- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

In the ever-evolving world of skincare packaging, where innovation meets the pursuit of beauty, the Skincare Tube Filling Machine emerges as an indispensable tool, seamlessly integrating precision with the artistry of skincare formulation. This advanced machine stands at the forefront of cosmetic technology, offering skincare manufacturers a reliable solution to meet the demands of discerning consumers. By unraveling its unique product characteristics, diverse applications, and the intricate mechanical principles guiding its operation, we delve into the essence of excellence in skincare tube filling. From silky moisturizers to revitalizing masks, this machine ensures each skincare product is dispensed with accuracy, consistency, and the promise of radiant transformation.

Product Characteristics:

The Skincare Tube Filling Machine showcases an array of exceptional characteristics meticulously engineered for precision and efficiency. Crafted from high-grade materials, often stainless steel, these machines ensure durability while adhering to the highest standards of quality. Featuring automated dosing systems, filling nozzles, and customizable settings, they cater to a spectrum of skincare viscosities, guaranteeing each product receives a consistent and accurate fill. Versatile in design, these machines accommodate various tube sizes and materials, from plastic to aluminum, offering flexibility in packaging choices. Advanced sensors and user-friendly interfaces enhance operational efficiency, minimizing wastage and optimizing resource utilization. Equipped with anti-drip mechanisms and secure sealing, these machines preserve the integrity of skincare formulations, delivering products that captivate with their quality and presentation.

Product Applications:

The applications of the Skincare Tube Filling Machine span the entire spectrum of skincare packaging, offering manufacturers a solution for efficient and precise filling of creams, lotions, serums, and various formulations into tubes. Whether producing small batches of specialized products or large-scale manufacturing of popular lines, these machines ensure uniformity in dosage and presentation. The adaptability of the Skincare Tube Filling Machine caters to the dynamic needs of the skincare industry, where each product requires a tailored approach to dispensing, sealing, and preserving the integrity of the formulation within the confines of a tube.

Mechanical Principle:

At its core, the Skincare Tube Filling Machine operates on advanced mechanical principles designed for delicacy, speed, and accuracy. Utilizing precision dosing pumps, conveyor systems, and filling nozzles, the machine accurately measures and dispenses the specified quantity of skincare products into individual tubes. Sealing mechanisms, employing high-speed heat sealing or ultrasonic sealing technology, secure the tubes, preserving the freshness and effectiveness of the skincare formulations. Integrated sensors and programmable logic controllers (PLCs) oversee the entire process, ensuring uniformity, minimizing errors, and enhancing the overall efficiency of skincare tube filling operations.

In conclusion, the Skincare Tube Filling Machine stands as a symbol of precision and efficiency in the skincare packaging domain. Its exceptional product characteristics, diverse applications, and advanced mechanical principles make it an indispensable asset for skincare manufacturers globally. Embracing cutting-edge technology, this machine not only ensures the accuracy of skincare tube filling but also upholds the highest standards of presentation, consistency, and quality. As a fundamental component in the creation of skincare essentials, it continues to shape the way skincare products are filled, ensuring each product embodies the essence of precision and technological sophistication.

Sensor

Main role is to sense the tube, and automatically turn the tube to ensure the standard.

Workflow: When the tube enters the machine bench, the sensor is automatic, adjusts the position of the pipe, and sends a signal to the next filling station. The internal program controls automatic filling

The control panel

This is the main workbench of the machine, the function is clear, the operation is simple, as long as adjust the corresponding button, the internal program will control the machine to run smoothly

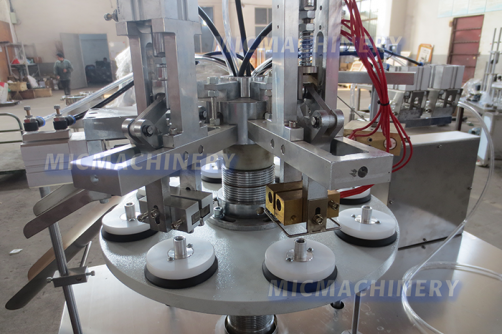

The main platform

Pictures include turntables, filling heads, sensors, heating heads, cutting and date printing stations. Its function is clear and easy to clean.

Main workflow: automatic on-line through pipeline. When the pipe comes, the sensor automatically recognizes it, sends a signal to the gas station, and begins refueling. After filling, the end of the pipe is heated, flattened, cut, date printed, and finally the pipe is topped.

We can customize this turntable, filling head, etc

pharmacy, cosmetic, cream, toothpaste, food and chemical etc.

This machine function is :1. Manual loading tube

2. Automatic benchmarking

3. Aumatic filling and no tube no filling and could be bottom filling system according to customer materail viscosity

4. Automatic heating (inner heating and outer heating)

5. Automatic sealing and printing the date code

6. Automatic cut the over part after sealing then output finish product

This machine body made by stainless steel, and the working process is controlled by buttons, and the filling speed is adjustable.

This machine is suitable for filling, sealing, printing and cutting of plastic tubes of various specifications. The shape of the sealing tail is beautiful and neat, the sealing is firm, the measuring accuracy is high, and the stability is good.According to customer materail viscosity could be heating and stiring hopper and bottom filling system.

According to customer’s requirement, we will offer our technician for oversea to install and adjust machine , We provide the full-lifetime warranty consult with one year free accessories, even two years. If you need, we also can arrange the engineer to your factory do field installation guidance.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

L30 |

L30I |

L45 |

L45I |

L60 |

L60I |

R30 |

R30I |

R45 |

R60 |

|

Application |

Pharmacy, cosmetic, food and chemical ,super glue, glue 502. etc. |

|||||||||

|

Packing Type |

Soft tube,aluminum tube,plastic tube. Etc |

|||||||||

|

Speed |

10-50 t/m |

25-45 t/m |

30-75 t/m |

40-45 t/m |

50-60 t/m |

50-60 t/m |

20-30 t/m |

20-30 t/m |

30-35 t/m |

30-65 t/m |

|

Filling Arrange |

1-300ml,2-300ml,3-20ml,5-75ml, 15-75ml, 75-250ml,5-75ml/75-150ml /150-300ml |

|||||||||

|

Power |

1.1Kw |

1.1kw |

2.2Kw |

2.2Kw |

2.2Kw |

2.2Kw |

1.1kw |

1.1Kw |

4KW |

5.5Kw |

|

Size |

1130*750*1680 mm |

1500*700*1800 mm |

1950*800*1850 mm |

1950*800*1850 mm |

1900*1400*2000 mm |

1900*1400*2000 mm |

1230*700*1400 mm

|

1230*700*1400 mm |

1450*1050*1750 mm |

1850*950*1980 mm |

|

Weight |

250Kg |

300Kg |

850Kg |

800 Kg |

850Kg |

1200 Kg |

250Kg |

250Kg |

475Kg |

850Kg |

In addition to,we have Skincare filling machine.If you are more than interested in the machine ,you can contact us at market@micmachinery.com

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.