- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

This filling machine is suitable for:

Widely used in food, chemical industry, medicine, cosmetics, pesticides and other industries, suitable for liquid filling, such as plastic bottles, glass bottles, gorilla bottles and so on.

This machine function is:

1. Automatic conveyor belt running

2. Automatic bottles feeding

3. Automatic four filling heads and filling

4. No bottles no filling

5. Can be customized according to different bottles shape and size

Product Description:

1) This machine is suitable for filling aqueous solutions and cream products, particularly for high viscosity materials (such as cosmetics, seed coating agent, motor lubricating oil, suspending agent etc.) the effect is obvious.

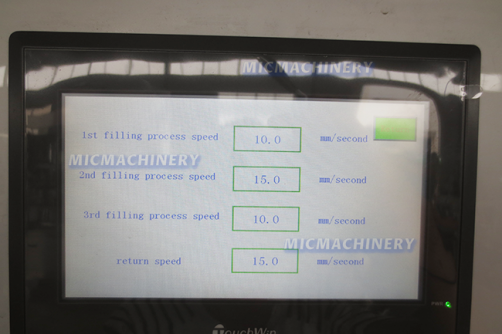

2) Using PLC programmable control, with touch screen and man-machine interface system; automatic bottle feeding, automatic filling, automatic send bottle out; driven by a servo motor, double screw drive, control the movement of the piston rod to ensure the stability of the filling, filling precision higher.

3) Used double liquid box and is provided with a filter plate, mechanical three-way easy to clean and replace the material more convenient. It can be with the capping machine, labeling machine supporting the formation of whole production line.

4) It integrates light, machine, electricity and gas into one body. Is an easy to operate filling machine. With stable and reliable operation, high production efficiency, strong adaptability.

Using the servo motor drive, double ball screw drive, to ensure the stability of the piston movement, high precision, from the surface to achieve accurate filling.

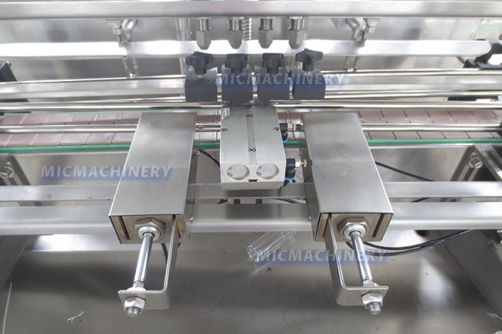

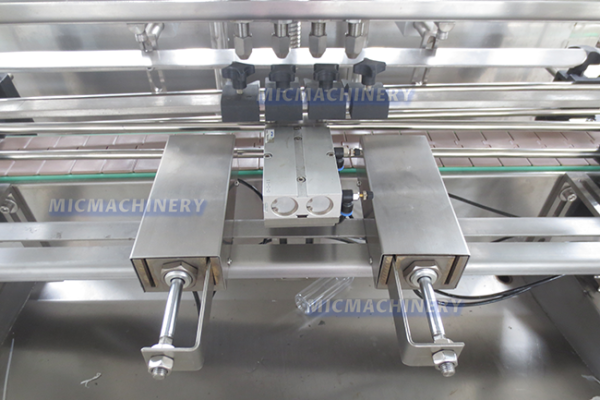

filling head

The material is put into the material cylinder, the piston to pump the material into the measuring cylinder. Then the piston moves up to send the material to the filling pipe. At the same time, when the bottle enters the filling machine through the conveyor belt, the filling head moves down to start filling. After filling, the conveyor belt will automatically send the bottle to the capping station.

(Filling process without drip leakage, the number of filling head can be customized according to your needs and diameter of filling head basis on the diameter of your barrel’s mouth)

the three-way valve and Measuring cylinder

the three-way valve is controlled by PLC system, The three-way valve rotates internally to adjust the connection between the material box and the measuring cylinder cylinder or the measuring cylinder cylinder and the filling pipe. Accordingly it controls the movement of materials from the material tank to the dosing cylinder and then to the filling pipe.

Measuring the effect of cylinder is primarily a quantitative filling, it allows you to have higher filling accuracy,

Main working process: downward movement of the piston to fill the material from the material cylinder to the measuring cylinder, and then controls the upward movement of the piston to send the material to the filling pipe and start filling.

Bottle block air cylinder

When the bottle can reach a certain number, there is a special infrared sensor on the bottle track to receive the induction, and then automatically stuck behind the bottle, in front of the bottle after the bottle filling, and then let the behind the bottle to fill the vacancy, so as to achieve no bottle no filling

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

About the machine use problem, after the sales,

we will take video for:

1. how to connect the power

2. how to operate the machine

3. how to maintain the machine and how often to do it

4. how to adjust machine to different bottle or material.

Thank you for the reading this article,

you can also check for:

→ QC Adjustment ←

→ Manual ←

|

Filling Nozzle |

4Pieces |

|

Filling Volume |

50ml-500ml |

|

Filling Speed |

≤2000bottle/hr base on 100ML |

|

Filling Form |

Piston Pump Type (Servo Control) |

|

Accuracy |

≤±3‰ |

|

Suitable Bottle Diameter |

Ф40mm-Ф200mm |

|

Material |

Surface: SUS304 Material Contact Part: SUS316 |

|

Control |

PLC and Touch Screen |

|

Air Pressure |

0.55Mpa-0.65Mpa |

|

Power |

3Kw |

|

Voltage |

380V/50Hz 3phase (Can be customized) |

|

Machine Size |

2000*1000*2500MM(L*W*H) |

|

Weight |

1500Kg |

|

Name |

Brand |

|

Press-button |

Schneider |

|

Magnetic Contactor |

Schneider |

|

Relay |

Omron |

|

Frequency Transformer |

Mitsubishi |

|

Motor |

JSCC Made in Germany |

|

Air Cylinder |

Airtac |

|

Solenoid Valve |

Airtac |

|

Speed Reducer |

Made in Taiwan |

|

Bearing |

NSK |

|

PLC |

Mitsubishi |

|

Touch Screen |

Mitsubishi |

|

Fibre-optical |

Autonics |

|

Switching Mode Power Supply |

NWELL |

|

Step Motor |

SNAYO Made in Japan |

- Penicillin bottle filling machine ( MIC-L40 Small glass Bottle Filling Corking And Seaming Machine )

- Gorilla Bottle Filling Machine(MIC-ZF4 Automatic small plastic bottle liquid filling machine)

- Oral liquid filling machine(MIC-L45 linear syrup and oral liquid filling machine)

- Syrup Filling Machine ( Speed 60-90 bottles per minute )

- Eye drops filling machine(MIC-L45 eyes drops plastic bottle with inner plug filling and capping machine)

- Gorilla Bottle Filling capping machine 2 in 1

- Eye drops high speed small volume bottle filling machine