- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In modern manufacturing, precision and efficiency in powder packaging are paramount for product integrity and customer satisfaction. The Powder Bag Packing Machine serves as a versatile solution, offering seamless and accurate packaging for various powdered products. Let's explore how this equipment optimizes performance, focusing on its role as a powder packing machine, powder filler, and powder packaging machine.

Maximizing Performance with the Powder Bag Packing Machine

Efficient Powder Packaging: The Powder Bag Packing Machine operates with exceptional efficiency, facilitating rapid and precise packaging of powdered products into bags. With its advanced filling and sealing mechanisms, this equipment streamlines the packaging process, minimizing production downtime, and maximizing throughput.

Versatile Packaging Solutions: Whether it's individual bags or bulk packaging, this machine offers versatile solutions to meet diverse product requirements. It efficiently fills and seals powdered products into bags of various sizes, providing flexibility in packaging options and ensuring products are accurately packaged for distribution or retail.

Precision and Consistency: Equipped with advanced filling and sealing mechanisms, the Powder Bag Packing Machine ensures precise and consistent packaging results. Whether filling small sachets or large bags, the equipment delivers uniform packaging, enhancing product presentation and customer satisfaction.

Serving as a Powder Packing Machine, Powder Filler, and Powder Packaging Machine

Powder Packing Machine: The Powder Bag Packing Machine serves as a dedicated powder packing machine, efficiently filling powdered products into bags. This method of packaging offers accuracy and reliability, ensuring product integrity and minimizing wastage during the packaging process.

Powder Filler: Excelling as a powder filler, this equipment accurately measures and dispenses powdered products into bags. Whether filling small sachets or large bags, the Powder Bag Packing Machine ensures precise filling levels, optimizing product consistency and quality.

Powder Packaging Machine: As a powder packaging machine, the Powder Bag Packing Machine efficiently fills, seals, and packages powdered products into bags. The packaging process is seamless, ensuring products are securely packaged and ready for distribution or retail.

Conclusion

The Powder Bag Packing Machine represents a pinnacle of efficiency, precision, and versatility in the powder packaging industry. Whether serving as a powder packing machine, powder filler, or powder packaging machine, it plays a crucial role in streamlining packaging processes and maintaining product quality. By investing in this advanced equipment, manufacturers can elevate their operations, enhance product presentation, and meet consumer expectations with confidence.

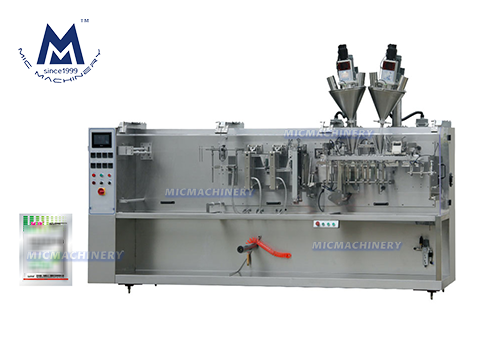

The fully automatic horizontal bagging machine includes a film laying, bag forming, bag bottom sealing, vertical sealing, cutting, bag opening filling, bag transfer, bag top sealing and the like. Through the motor drive the cam on the main shaft to complete the coordinated action of each mechanism, and the encoder on the spindle feedback position signal, under the programmable control of the PLC, realizes the film roll → bag forming → bag making → filling → sealing → finished product conveying The function, the final product enters the bag picking and counting device for shunting, and is manually packed or boxed. The machine is reasonable in design, novel in appearance, and adopts standard stripe sealing. The filling of the filling device can realize automatic filling of various materials such as powder, granule, suspension agent, emulsifiable oil and water agent on the machine.

Main Features

1) Can customize Three or four sides can be sealed as needed

2) Single and double bag options are also available

3) The whole machine is made of SUS304 stainless steel, which has good anti-corrosion effect on corrosive materials.

4) The plexiglass cover prevents dust from leaking out, making it more environmentally friendly and non-polluting.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.ent bottle or material.