- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

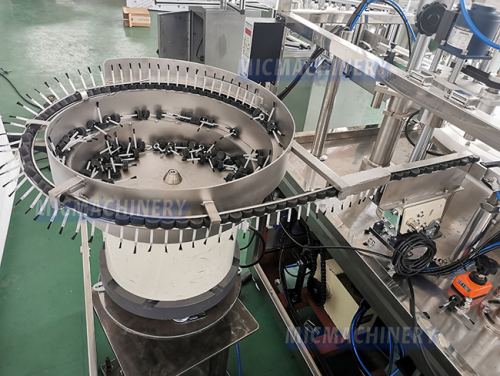

This machine is mainly available to fill nail glue into various round and flat glass and plastic bottles with the filling range from 5-20ml.High precision cam provides a regular plate to position, inner ,brush and cap; accelerating cam makes capping heads going up and down ;constant turning arm screws caps; peristaltic pump and pressure tank filling time measures filling volume; and touch screen controls all action. No bottle no filling and no capping. If there is no plug in the bottle, it must not cap until having been detected plug in the bottle. The machine with advantage of high position.

This machine function is :

1. Automatic feeding bottle

2. Adopt pressure tank and peristaltic pump fillling ,suitable different viscosity glue and liquids.

4. Automatic filling and three vibrating bowl uploading plug, brush and cap

5. Automatic capping , no bottle no filling and no cap loading

6. Adopt PLC touch screen control , easy to operate

This machine body made by stainless steel, and the working process is controlled by touch screen ,the filling speed and filling volume is adjustable.

This machine is suitable for filling, plug uploading, brush uploading,cap uploading and capping of glass bottle of various specifications. Filling volume is adjustable , the turntable could according to customer bottle shape and size to custom made . Also , it could connection with bottle feeding table , bottle collecting table and labeling machine to use.

Automatic Nail Polish Filling Machine with functions of automatic filling, loading brush and capping. The filling device adopts bottle positioning mechanism to solve the problem of large size deviation of the nail polish filling glass container that the filling nozzle can not be put into the container. The storage bucket uses the way of pressure feeding by separating from the main machine. The volume of the bucket can be customized by customers and place the storage bucket randomly. That alternate use of multiple storage buckets effectively shorten the time for replacement of different materials. Adopt the approach of mechanical arm fetching cap, pre-spin to cover, which solve the problem of brush poor positioning, and cannot cover .Capping device with a torque adjusting device, capping torque can be adjusted according to customer's requirement.

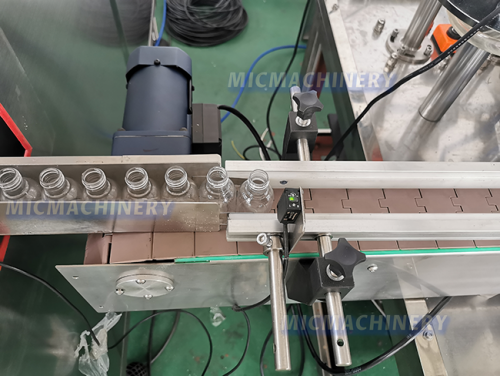

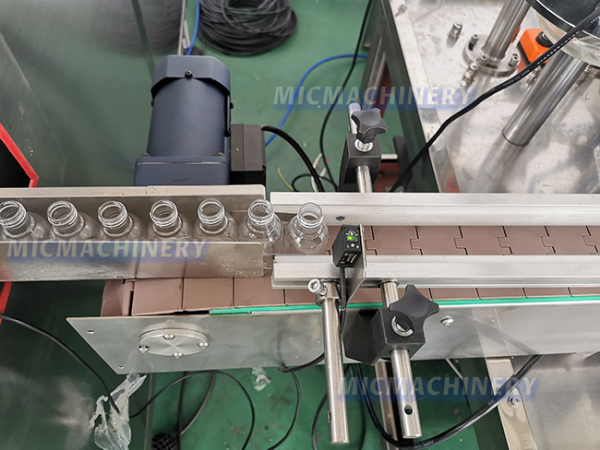

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of bottle,The width between the two pipes can be adjusted according to your container,ensure smooth bottle safely from the conveyor belt moved .

on the side of the conveyor is equipped with sensors that can automatically identify when the bottle to go out or, in order to send signals to filling station of screw cap.

Filling head

When the bottle through the conveyor belt was sent to the location of the chuck, automatic identification of sensors, control by internal program to send signals for filling station, when the bottle comes under the filling head, cylinder head began to move down the drive filling, filling process without dripping, do not waste material, also can ensure the bottle clean and tidy, convenient after labeling.

Control panel by Siemens touch screen

The control panel on the filling machine is the core of the machine,it consists of touch screen,power switch, emergency button You just need to press the corresponding button and the machine will follow the correct program.

An Alarm Screen will also be included on automatic filling equipment to notify packagers when there is an issue with the filling equipment or the packaging line in general. In addition to notification, the screen can assist with identifying the issue if the same is not immediately obvious.

If you want to know more models of filling machine, you can refer to the table below:

|

Vial Filling Machine |

||||||||

|

model |

FC-30 |

FC-X40 |

FC-P35 |

FC-P40 |

FC-T30 |

FC-N25 |

FC-E35 |

FC-Z40 |

|

application |

cosmetics, daily chemical and pharmaceutical industries such as nail polish, e-liquid, eye drop,etc |

|||||||

|

Packing type |

various round and flat glass and plastic bottles,etc |

|||||||

|

speed |

23-30pcs/min |

30-50pcs/min |

30-40pcs/min |

25-30pcs/min |

20-30pcs/min |

15-25pcs/min |

30-40pcs/min |

30-50pcs/min |

|

Filling arrange |

50-250ML |

10-100ML |

10-100ML |

10-100ML |

30-120ML |

2-30ML |

10-100ML |

20-150ML |

|

power |

5kw |

2KW |

2KW |

5KW |

2KW |

2KW |

2KW |

2KW |

|

size |

2000*1000*1700mm |

1800*1000*1500mm |

1800*1000*1500 mm |

1800*1000*1500 mm |

1800*1000*1500 mm |

1800*1000*1500 mm |

1800*1000*1500 mm |

2000*1000*1500 mm |

|

weight |

650KG |

550KG |

650KG |

650KW |

650KG |

650KG |

650KG |

600KG |

In addition to,If you're looking for nail polish filling machine ,nail polish bottle filling machine,automatic nail polish filling machine,nail polish filling and capping machine,it is a pleasure for you to visit our website anytime.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Voltage |

220V 50Hz/380v |

|

Power |

2.5kw |

|

Air Pressure |

0.6-0.8Mpa |

|

Air Consumption |

30dm^3/MIN |

|

Production Capacity |

20-30 bottles/minute |

|

Filling Error |

+/-1% |

|

Dimensions |

2000*1000*1800mm |

|

Weight |

500kg |

|

Filling Volume |

5-20ml |

| Parts | Brand |

|

Button |

Schneider |

|

AC Contactor |

Schneider |

|

Relay |

Schneider |

|

Frequency Converter |

Taian |

|

Motor |

Qi peng |

|

Air Cylinder |

AIR TAC |

|

The electromagnetic valve |

AIR TAC |

|

Bearing |

NSK |

|

PLC |

Schneider |

|

Touch Screen |

Schneider |

|

Photoelectric Detection |

Sick |

|

peristaltic pump control filling Servo motor + drive |

TouchWin |

- Nail glue filling capping machine(MIC Full automatic nail glue filling capping machine)

- Mascara filling machine(MIC-L40 mascara filling capping machine)

- Lip gloss filling machine (MIC-L45 lip gloss filling machine)

- Nail polish filling and capping machine (MIC-L45 nail polish filling capping machine)

- Automatic Mascara Pen Filling Capping Machine

- Semi automatic Mascara and Lip Gloss tube filling machine

- Semi-automatic mascara lipgloss filling machine