- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Product Characteristics:

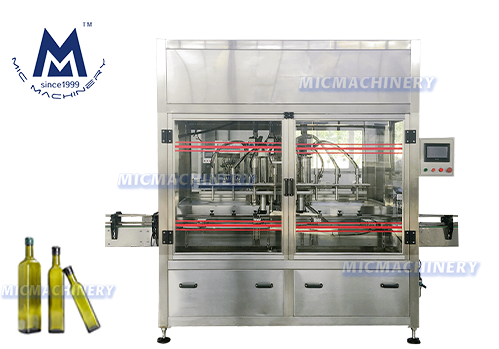

The glass bottle filling machine we present boasts a remarkable set of characteristics designed to meet the highest industry standards. Featuring a four-head linear filling mechanism, this machine is a testament to precision and speed. Its state-of-the-art design ensures a seamless filling process, guaranteeing accuracy and consistency with every cycle. The reliability and durability of this machine make it an indispensable asset for businesses seeking excellence in their liquid packaging operations.

Product Application:

Versatility is a key aspect of this glass bottling marvel. Tailored for the filling of edible oil, it excels in handling various viscosities and ensures a spill-free, controlled filling process. Whether you are a small-scale artisanal producer or a large-scale industrial enterprise, this glass bottle filling line is adaptable to diverse production environments. It is your go-to solution for achieving optimal results in the packaging of edible oils in glass bottles, ensuring the integrity of your product from production line to end consumer.

Mechanical Principle:

At the heart of this glass bottle filling machine lies a sophisticated mechanical principle that sets it apart. The four heads linear filling mechanism operates seamlessly, allowing for the simultaneous filling of multiple bottles with unparalleled efficiency. This not only accelerates the production process but also maintains a high level of accuracy. The machine's intuitive design ensures minimal downtime, contributing to increased productivity and a more streamlined production line.

In conclusion, our glass bottle filling machine is more than just a piece of equipment; it's a game-changer in the world of liquid packaging. Its exceptional characteristics, versatile applications, and robust mechanical principles make it the ideal choice for businesses seeking precision and efficiency in filling glass bottles with edible oil. Elevate your packaging process with a machine that goes beyond expectations, ensuring your products reach consumers with the quality they deserve.

filling head

The oil is put into the material cylinder, and the piston to pump the oil into the measuring cylinder. Then the piston moves up to send the oil to the filling pipe. At the same time, when the bottle enters the filling machine through the conveyor belt, the filling head moves down to start filling. After filling, the conveyor belt will automatically send the bottle to the capping station.

(Filling process without drip leakage, the number of filling head can be customized according to your needs and diameter of filling head basis on the diameter of your barrel’s mouth)

the three-way valve

the three-way valve is controlled by PLC system, The three-way valve rotates internally to adjust the connection between the material box and the measuring cylinder cylinder or the measuring cylinder cylinder and the filling pipe. Accordingly it controls the movement of materials from the material tank to the dosing cylinder and then to the filling pipe.

Main working process: downward movement of the piston to fill the material from the material cylinder to the measuring cylinder, and then controls the upward movement of the piston to send the material to the filling pipe and start filling

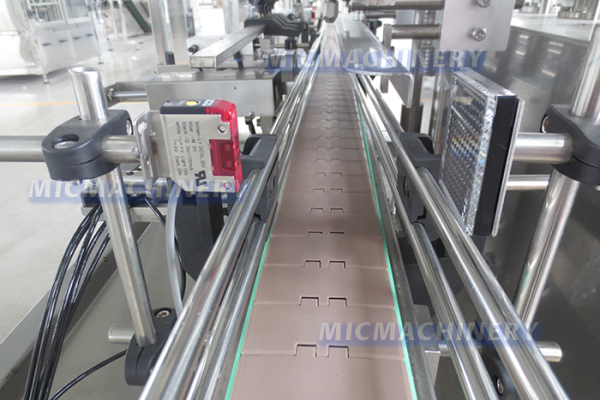

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of bottle,The width between the two pipes can be adjusted according to your container,ensure smooth bottle safely from the conveyor belt moved .

on the side of the conveyor is equipped with sensors that can automatically identify when the bottle to go out or, in order to send signals to filling station of screw cap

olive oil, sunflower oil, bean oil, seasam-seed oil, vegetables oil, edible oil, peanut oil, palm oil, corn oil, sauce and other similar products.

This machine function is:

1. Automatic bottle sensing system and filling

2. No bottle no filling

3. Filling error is control within 1‰

4. Filling arrange : mini volume: max volume =1:10

5. Automatic filling volume correction system.

6. Can be customized for different bottle and caps.

7. Can be equipped with cleaning system.

Olive Oil Filling Machine Mainly Shows:

1. Place the bottle on the conveyor belt

2. Servo motor piston filling when the bottle reaches the designated spot

3. Bottle cap sorting and corking one by one

4. Bottle cap screwing

5. Finally checking for sealing appearance

This machine filling system is made for cosmetics package food bottle medical products and chemical products, easy clean and changes, we have automatic piston opening for cleaning. it is a practical machine for production and clean, 24 hours runs none stops, hardly have machine break down once well adjusted.

Machine filling accuracy max is at 1%, from 100ML-1000ML, 1L-5L volume, and it is piston filling controlled by servo motor.

This machine is mechanical transmission, controlled by servo motor, it is well developed machine, use life more than 15 years.

This machine is guaranteed for one year and you can extent your guarantee easily by discuss with our sales.

Which you might be interested, under guaranteed, machine parts got broken by daily use, we will replace it once we are informed by free DHL.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

In addition to,we have edible oil filling machine,olive oil filling machine,cooking oil filling machine,vegetable oil filling machine,olive oil bottling machine

If you are more than interested in the machine ,you can contact us at market@micmachinery.com

This is the good comment we received from our customers.If you need anything,you can also contract our sales.They will try their best to meet your needs.