- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Welcome to the pinnacle of liquid packaging efficiency with our state-of-the-art glass bottle filling and capping machine. In an industry where precision and speed are paramount, our eight heads linear filling machine is designed to redefine your liquid packaging experience. Let's delve into the exceptional product characteristics, versatile applications, and robust mechanical principles that make this machine a game-changer, tailored for filling glass bottles with Detergent and Lube Oil.

Product Characteristics:

Our glass bottle filling and capping machine stand out with advanced features that set new benchmarks in the industry. Boasting an eight-head linear filling mechanism, this machine is a paragon of precision and speed, ensuring a seamless and reliable packaging process. Its design guarantees accuracy and consistency with every fill, making it a reliable asset for businesses seeking to enhance their liquid packaging operations. The durability and reliability of this machine make it indispensable for maintaining optimal production standards.

Product Application:

Versatility is a key feature of our glass bottle packaging machine, perfectly suited for filling glass bottles with both Detergent and Lube Oil. Tailored to handle a range of viscosities, the eight heads linear filling machine ensures a controlled and spill-free filling process. Whether you're a small-scale manufacturer or an industrial giant, this machine adapts seamlessly to various production environments. It stands as the optimal solution for achieving top-tier results in packaging detergents and lube oils in glass bottles, safeguarding the quality of your products throughout the production line.

Mechanical Principle:

At the heart of this glass bottle filling and capping machine lies a sophisticated eight-head linear filling mechanism that operates seamlessly. This enables the simultaneous filling of multiple bottles with unparalleled efficiency, accelerating the production process while maintaining precision. The machine's intuitive design minimizes downtime, contributing to heightened productivity and a more streamlined production line.

In conclusion, our glass bottle filling and capping machine is not just a piece of equipment; it's a revolutionary solution for liquid packaging needs. With exceptional product characteristics, versatile applications, and robust mechanical principles, it stands as the ideal choice for businesses seeking precision and efficiency in filling glass bottles with Detergent and Lube Oil. Elevate your packaging process with a machine that exceeds expectations, ensuring your products reach consumers with the quality they deserve.

filling head

The Liquid detergent is put into the material cylinder, and the piston to pump the Liquid detergent into the measuring cylinder. Then the piston moves up to send the Liquid detergent to the filling pipe. At the same time, when the bottle enters the filling machine through the conveyor belt, the filling head moves down to start filling. After filling, the conveyor belt will automatically send the bottle to the capping station.

(Filling process without drip leakage, the number of filling head can be customized according to your needs and diameter of filling head basis on the diameter of your barrel’s mouth)

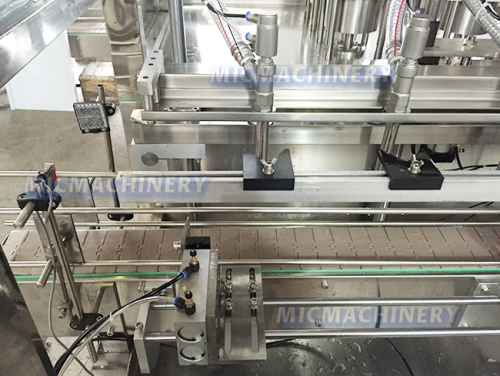

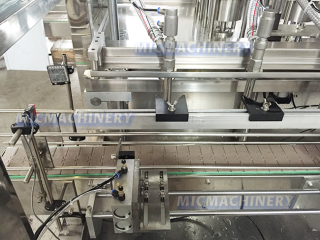

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of bottle,The width between the two pipes can be adjusted according to your container,ensure smooth bottle safely from the conveyor belt moved .

on the side of the conveyor is equipped with sensors that can automatically identify when the bottle to go out or, in order to send signals to filling station of screw cap

1. Adopt PLC programmable control system with touch screen interface.

2. Automatic bottle feeding, automatic filling, automatic bottle.

3. Adopt servo motor drive, double screw-rod drive, Control the movement of the piston rod to ensure the stability of the filling.

4. Adopt double-ball screw rod filling the filling nozzle dive

5. It can be used with capping machine, labeling machine supporting the formation of the production line

6. It combines optical, mechanical, electrical, gas in one. It is easy to operate a filling machine.

7. Having a stable and reliable operation, high production efficiency, strong adaptability.

Honey Filling Machine Mainly Shows:

1.Place the bottle on the conveyor belt

2.Servo motor piston filling when the bottle reaches the designated spot

3.Manually cap the bottle

4.Bottle cap screwing

5.Label the bottle on both sides

6.Finally checking for sealing appearance and packing in the boxes

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |