- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

This machine is suitable for syrup and oral liquid filling and capping. It is widely used in food, pharmaceutical, chemical industries and scientific research as well.

Characteristic:

1. Human-machine interface settings, an easy and intuitive, PLC control.

2. Frequency control, the production rate be adjusted automatically count.

3. No bottle no filling.

4. High-precision cam meter control, precise positioning.

5. SUS304 and 316L stainless steel

Screw capping head

His job is to tighten the lid on a bottle that has been filled , which is the last step on the main bench.

When the bottle reaches under the Screw capping head, the machine automatically recognizes and the Screw capping head moves downward to tighten the cap quickly.

cover loading automatically

Cover feeding cage with vibrating disk is connected to a pipe that carries the outside cover ,They automatically arranges the outside cover and deliver the outside cover.

In this way, the small bottle is covered in a Coherent process, reducing the manual contact with the syringe process, and ensuring bottle hygiene,At the same time, labor costs are reduced.

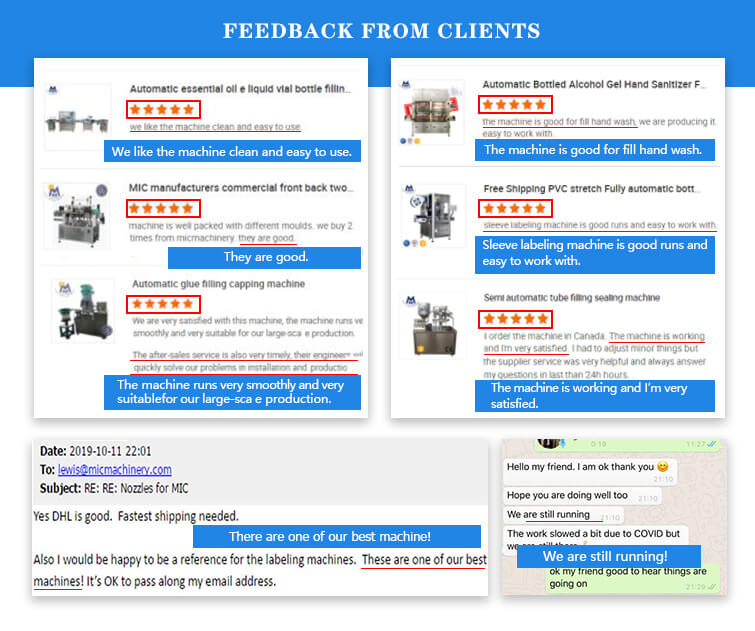

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback:

| Model | MIC-L45 |

| Filling volume | 25-80 ML (As requirement) |

| Filling nozzle | 4 nozzles |

| loading error | ≤ ±1% |

| Rotation (rolling) Cover pass rate | ≥99% |

| Production capacity | 30-50BPM |

| Power supply | 380V/50Hz(According to customer) |

| Power | 2.0 kw |

| Weight | 600 kg |

| Dimension | 2000*1000*1500mm |

| Name | Brand |

| Button | Schneider |

| AC contactor | Schneider |

| Relay | Schneider |

| Frequency converter | Schneider |

| Motor | Qi peng |

| Air cylinder | AIR TAC |

| The electromagnetic valve | AIR TAC |

| Bearing | NSK |

| PLC | Schneider |

| Touch screen | Schneider |

| Photoelectric detection | Sick |

| If the peristaltic pump control filling will use servo motor Servo motor + drive | Schneider |

- Penicillin bottle filling machine ( MIC-L40 Small glass Bottle Filling Corking And Seaming Machine )

- Gorilla Bottle Filling Machine(MIC-ZF4 Automatic small plastic bottle liquid filling machine)

- Oral liquid filling machine(MIC-L45 linear syrup and oral liquid filling machine)

- Syrup Filling Machine ( Speed 60-90 bottles per minute )

- Eye drops filling machine(MIC-L45 eyes drops plastic bottle with inner plug filling and capping machine)

- Gorilla Bottle Filling capping machine 2 in 1

- Eye drops high speed small volume bottle filling machine