- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In industries handling corrosive liquids, such as chemicals or cleaning agents, precision, safety, and efficiency are paramount for maintaining operational integrity and meeting stringent quality standards. Enter the 12-heads linear corrosive liquid filling machine, a state-of-the-art solution designed to optimize performance and ensure the safe and efficient filling of corrosive liquids. Let's delve into how this advanced equipment enhances machine performance, focusing on its role as an anti-corrosive liquid filling machine, corrosive liquid filling machine, and automatic corrosive liquid filling machine.

Maximizing Performance with the 12-Heads Linear Corrosive Liquid Filling Machine

Efficiency Enhancement: Equipped with twelve heads, this filling machine operates with exceptional efficiency, enabling rapid and simultaneous filling of multiple containers with corrosive liquids. This multi-head configuration significantly boosts production throughput, minimizing downtime, and maximizing resource utilization.

Precision Engineering: The linear filling mechanism ensures precise dosing of corrosive liquids into each container. Advanced control systems and precision dosing mechanisms maintain consistent fill levels, enhancing product quality, and minimizing wastage while reducing the risk of spills or leaks.

Safety Measures: Built with materials resistant to corrosion, such as stainless steel or specialized plastics, the 12-heads linear filling machine ensures the safe handling of corrosive liquids. Robust construction and stringent safety features mitigate the risk of chemical reactions or damage to the equipment, safeguarding both operators and the production environment.

Serving as an Anti-Corrosive Liquid Filling Machine, Corrosive Liquid Filling Machine, and Automatic Corrosive Liquid Filling Machine

Anti-Corrosive Liquid Filling Machine: As an anti-corrosive liquid filling machine, the 12-heads linear model is specifically designed to handle corrosive substances safely and efficiently. Its corrosion-resistant materials and specialized components protect against degradation, ensuring the integrity of both the equipment and the filled product.

Corrosive Liquid Filling Machine: Tailored for corrosive liquid filling applications, this machine streamlines the process of accurately dispensing corrosive liquids into various containers. Its advanced technology and robust construction provide reliable performance, even in demanding industrial environments.

Automatic Corrosive Liquid Filling Machine: Designed for fully automated operation, this machine offers hands-free filling of corrosive liquids, maximizing efficiency and minimizing operator intervention. Its intuitive controls and programmable settings enable seamless integration into automated production lines, optimizing workflow and productivity.

Conclusion

In industries handling corrosive liquids, the 12-heads linear filling machine stands as a symbol of efficiency, precision, and safety. Its role as an anti-corrosive liquid filling machine, corrosive liquid filling machine, and automatic corrosive liquid filling machine underscores its importance in maintaining operational integrity and meeting regulatory requirements. By investing in this advanced equipment, manufacturers can optimize their processes, enhance safety standards, and ensure the consistent quality of their products, even in the most challenging environments.

This filling machine is suitable for:

pesticides, chemicals, bottled agent type liquid dispensing, bottle filling, Applicable to a variety of different types of containers.

This machine function is:

1. This machine combines optical, mechanical, electrical, gas in one machine.

2. Adopt through control filling time to reach different volume filling.

3. Filling time can be precisely controlled to a hundredth of a second.

4. The filling process is completed under the PLC program control on the touch screen.

5. Having a stable and reliable operation, high efficiency, adaptability, the filling volume of measurement specification can be changed within a few minutes.

6. Filling valve use imported brands, advanced technology, sophisticated, non-drip filling phenomenon.

7. All parts frame, conveyor ,valve ,filling nozzle use anti-corrosion material.

8. Can customize vacuum or diving filling avoid have foma when filling.

This machine is our MIC automatic inline straight line normal pressure filling machine, can Prevent corrosion.

It can be used with capping machine, labeling machine supporting the formation of the production line.

This machine is guaranteed for one year and you can extent your guarantee easily by discuss with our sales.

Which you might be interested, under guaranteed, machine parts got broken by daily use, we will replace it once we are informed by free DHL.

filling head

This machine is specially designed for filling corrosive liquids. All parts in contact with the liquid are made of antiseptic materials.

Main work process: When the bottle is under the filling head, the internal system controls the anti-corrosion filling head to move down, precise filling, no bottle no filling, special design can achieve no bubble filling.

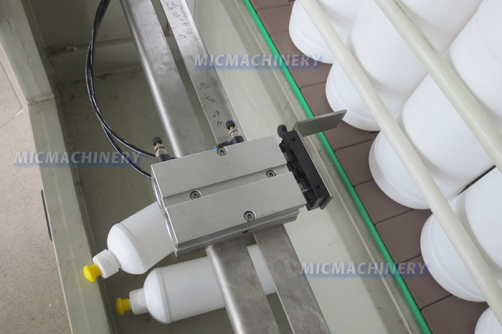

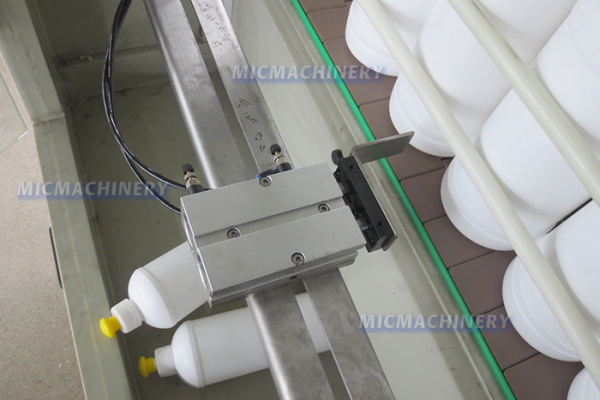

Bottle block air cylinder

When the bottle can reach a certain number, there is a special infrared sensor on the bottle track to receive the induction, and then automatically stuck behind the bottle, in front of the bottle after the bottle filling, and then let the behind the bottle to fill the vacancy, so as to achieve no bottle no filling

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of bottle,The width between the two pipes can be adjusted according to your container,ensure smooth bottle safely from the conveyor belt moved .

on the side of the conveyor is equipped with sensors that can automatically identify when the bottle to go out or, in order to send signals to filling station of screw cap

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback: