- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Product Characteristics:

Our automatic cup filling and sealing machine is distinguished by advanced features that make it a standout in the market. Compact and efficient, this small cup filling machine is a powerhouse of precision and speed. Its design incorporates the latest technological innovations, ensuring each fill is executed with seamless accuracy. The machine's commitment to reliability and consistency makes it an indispensable asset for businesses seeking to optimize their liquid packaging operations. Despite its size, this machine embodies durability, speed, and precision, setting new standards in the industry.

Product Application:

Versatility is the key strength of our rotary cup filling machine, tailored to fill plastic cups with a variety of products such as Sauce, Honey, and Yogurt. This machine excels in handling diverse viscosities, ensuring a controlled and mess-free filling process. Whether you're a small-scale producer or a burgeoning enterprise, the automatic cup filling and sealing machine seamlessly adapts to various production environments. It stands as the optimal solution for achieving exceptional results in packaging sauces, honey, and yogurt in plastic cups, maintaining the highest standards of product integrity.

Mechanical Principle:

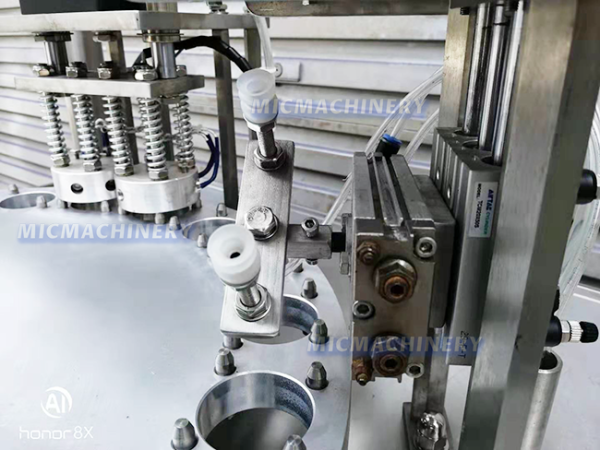

At the heart of this cup filling sealing machine lies a sophisticated rotary filling mechanism, operating seamlessly to provide unparalleled efficiency. The machine is designed to fill and seal cups with precision, ensuring a seamless packaging process. Its intuitive design minimizes downtime, contributing to enhanced productivity and a more streamlined production line. As a result, it stands as an excellent choice for businesses looking to elevate their liquid packaging operations while maintaining a compact footprint.

In conclusion, our automatic cup filling and sealing machine is not just a solution; it's a revolution in liquid packaging. With outstanding product characteristics, versatile applications, and robust mechanical principles, it stands as the ideal choice for businesses seeking precision and efficiency in filling plastic cups with Sauce, Honey, and Yogurt. Elevate your packaging process with a machine that goes beyond expectations, ensuring your products reach consumers with the quality they deserve.

The machine adopts PLC control, according to the filling cup, fixed discharging mouth, the rest all operation can be finished on a touch screen. In addition to have common automatic piston filling machine advantages, also the widened the range of filling material. Such as filling material contains particles, long strips of solid content, also can be a very effective filling.

1. Available with standard conveyor or with pucks for unstable cups

2. Flexible design

3. Very fast and easy changeover of format size

4. Docking filling station model available

5. Anti-dripping filling nozzle

cup loading station

Put the finished cups into the cup loading station. When the machine receives the start signal, the cup loading station will automatically drop the cups to be filled into the mold accurately, which is convenient for later filling.

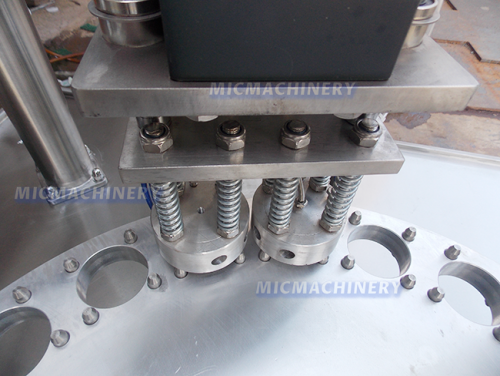

foil loading sucking disks

The device is designed to absorb the sealed tin foil film with a moderate suction force. When the cup reaches the desired position, the two pieces of foil are automatically absorbed and placed on the cup with precision. The working process is time-saving and stable

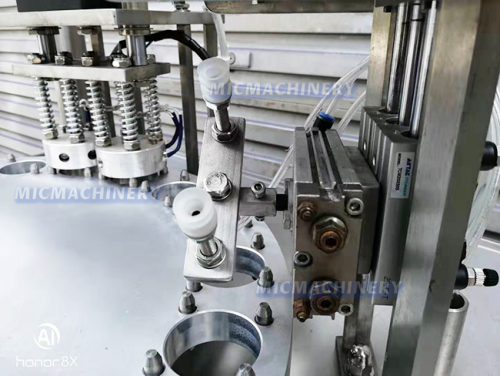

filling head

This machine adopts automatic piston filling, can ensure the precise filling you need filling quantity, the whole process without drip leakage, no waste of materials.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback: