- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

In the landscape of industrial manufacturing, efficiency and precision intersect with the Drum Filling Machine. This advanced apparatus seamlessly integrates technological innovation with operational excellence, providing businesses with a reliable solution for automating the filling of drums with accuracy and speed. Let's explore the distinctive features, versatile applications, and intricate mechanical principles of this transformative device reshaping industrial processes.

Product Characteristics:

The Drum Filling Machine embodies a host of exceptional features meticulously engineered for precise and efficient filling. Constructed from durable materials like stainless steel, it ensures longevity and adherence to the highest quality standards. Equipped with fully automated dosing systems, customizable settings, and user-friendly interfaces, this machine offers seamless automation while retaining control over the filling process. Its adjustable controls accommodate various viscosities of liquids, ensuring consistent and accurate fills for each drum. With anti-drip mechanisms and secure sealing, it preserves the integrity of contents, delivering products of unparalleled quality and reliability.

Product Applications:

The applications of the Drum Filling Machine cater to the diverse needs of industrial operations. Ideal for medium to large-scale production, it excels in filling drums with liquids such as chemicals, lubricants, and food products where precision is paramount. Businesses leverage its versatility for custom formulations, ensuring each drum receives a precise fill. Whether handling hazardous substances or processing bulk materials, the Drum Filling Machine serves as an indispensable tool for achieving operational excellence with finesse.

Mechanical Principle:

At its core, the Drum Filling Machine operates on advanced mechanical principles designed for precision and adaptability. Utilizing fully automated dosing pumps, conveyor systems, and precision filling nozzles, it accurately measures and dispenses precise quantities of liquids into individual drums. Temperature controls maintain optimal consistency, while integrated sensors and programmable logic controllers oversee the fully automated process. This precision ensures uniformity, minimizing errors and maximizing efficiency while upholding safety standards in industrial environments.

In conclusion, the Drum Filling Machine represents the pinnacle of synergy between technology and operational excellence in industrial manufacturing. Its exceptional characteristics, diverse applications, and balanced mechanical principles make it an indispensable asset for businesses seeking the perfect blend of precision and automation. As a cornerstone of streamlined operations, it continues to redefine industry standards, ensuring each filled drum embodies the essence of efficiency, reliability, and operational excellence.

1.This machine adopt PLC control system combine with weight system to control all machine.

2.Use fixed flow pipeline to set parameter.

3. Adopt large flow quality to control to reach approaching numerical( the set flow quality,such as set 20L, it will flow large quality to approaching 20L)

4.Then through small flow quality to supplement remain quality, in order to reach set quality filling, promise the filling quality is accuracy, and do not waste the material.

5.Filling volume range can adjust between 5L-25L.

6.This machine meeting GMP standard.

barrel block air cylinder

When the barrel can reach a certain number, there is a special infrared sensor on the barrel track to receive the induction, and then automatically stuck behind the barrel, in front of the barrel after the barrel filling, and then let the behind the barrel to fill the vacancy, so as to achieve no barrel no filling

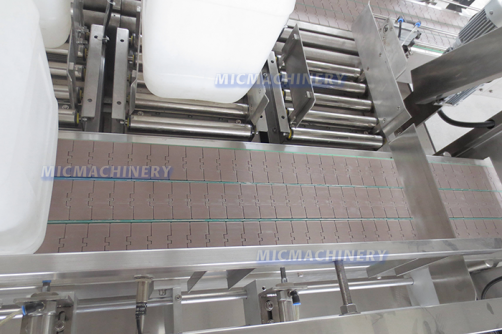

Glide wheel conveyor

This kind of roller track is particularly suitable for the use of large capacity barrels, because large capacity barrels are not convenient to move, time-consuming and laborious, if the machine is equipped with this kind of rolling track can be convenient to move, effectively save manpower.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

pesticides,chemical,cosmetic and other corrosive,High Viscosity Materials, Liquid soap , oil product ,Lotion And So On |

|||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

|||||

|

Speed (basis on 50-500ml) |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

|||||

|

Power |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

In addition to,If you're looking for Barrel Filling Machine,automatic barrel filling machine,it is a pleasure for you to visit our website anytime

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

Filling head

4 heads

Filling volume range

5L-25L

Production speed

192-220 b/h (25L for example)

Voltage

380V three-phase four-wire

Power

3.0Kw

Long barrels

180mm-300mm

Wide application barrels

120mm-250mm

Apply high barrel

280mm-450mm

Filling error

≤±3‰

Air consumption

0.6m3/min

Work pressure

0.55Mpa-0.65Mpa

Size

2500mm × 1600mm× 2500mm

Weight

700 kg

|

Touch screen |

Canada xinjie color |

|

PLC |

Schneider |

|

Solenoid valve |

Taiwan Airtac |

|

Optoelectronic system |

OPTEX |

|

Micro differential pressure switch |

Netherlands |

|

Servo motor |

Taiwan TECO |

|

Air source treatment |

Taiwan Airtac |

|

Button and low voltage electric appliance |

Schneider |

|

Ball screw |

Taiwan |

|

Reducer |

Taiwan VGM |

|

Switching power supply |

Taiwan meanwell |

|

Material |

Contact with the material parts of the 316 materials, and the rest of the 304 stainless steel |

- MIC-ZF4 Automatic Barrel Filling Machine ( 300 Barrels/h )

- MIC-ZF4 Drum Filling Machine ( 190-220 Drums/h )

- MIC2T-200L Automatic Drum Filling Machine ( 50-100 Drums/h )

- MIC1T-200L Drum Filling Line ( 20-30 Drums/h )

- MIC1T-20L IBC Filling Machine ( 60-150 Barrels/h )

- MIC Barrel Filling Machine ( 5 Barrle/h )

- MICIT-1000L Semi Automatic Barrel Filling Machine ( 8-12 Barrels/h )

- MIC-XG2 2 Two Heads Drum Filling Machine (600-1200Bottles/h)