- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

In the manufacturing industry, efficiency is paramount, and the Barrel Filling Machine emerges as a game-changer. Seamlessly combining innovation with precision, this machine revolutionizes the process of filling barrels with unparalleled speed and accuracy. In this comprehensive guide, we explore the key features, diverse applications, and mechanical principles of the Barrel Filling Machine, ensuring your production line operates at peak efficiency while maximizing quality.

Product Characteristics:

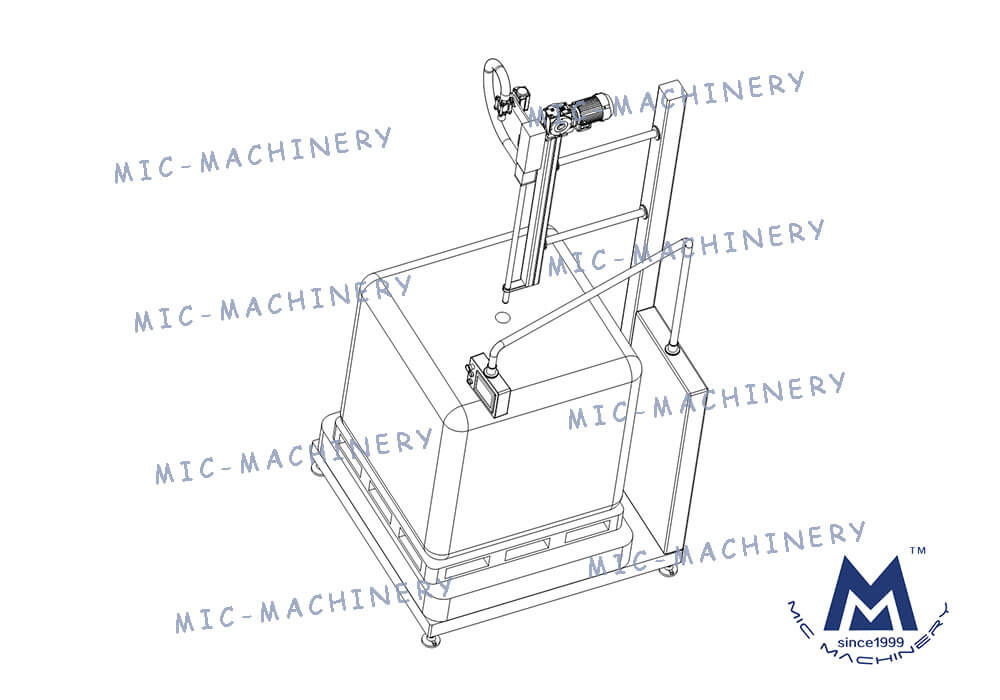

The Barrel Filling Machine boasts a host of exceptional features designed for optimal performance. Crafted from durable materials like stainless steel, it guarantees longevity and adherence to stringent quality standards. Equipped with advanced automation technologies, customizable settings, and intuitive interfaces, this machine offers seamless operation and precise control over the filling process. Its versatility accommodates various barrel sizes and types, ensuring consistent and accurate fills every time. With built-in safety features and robust construction, it ensures the integrity of your product while enhancing production efficiency.

Product Applications:

The applications of the Barrel Filling Machine span across industries, catering to diverse needs in the manufacturing landscape. From chemicals and lubricants to food and beverages, this machine is indispensable for filling barrels with liquids of varying viscosities. Ideal for medium to large-scale production, it excels in ensuring uniform fills and minimizing wastage, thereby optimizing resource utilization. Whether filling drums with oils, solvents, or syrups, the Barrel Filling Machine is your go-to solution for streamlined production and consistent quality.

Mechanical Principle:

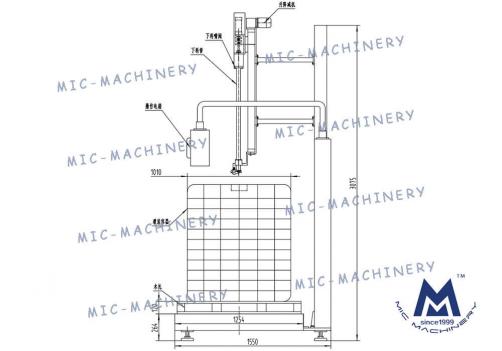

At its core, the Barrel Filling Machine operates on advanced mechanical principles designed for precision and reliability. Utilizing automated pumps, conveyor systems, and filling nozzles, it accurately measures and dispenses precise quantities of liquid into each barrel. Integrated sensors and programmable logic controllers oversee the entire process, ensuring uniform fills and minimizing errors. Temperature controls maintain product integrity, while anti-drip mechanisms prevent spillage, further enhancing efficiency and safety in the production environment.

In conclusion, the Barrel Filling Machine represents the epitome of efficiency and precision in barrel filling operations. Its exceptional characteristics, diverse applications, and robust mechanical principles make it an indispensable asset for manufacturers across industries. By investing in this cutting-edge technology, you can streamline your production processes, minimize wastage, and elevate the quality of your products, ensuring your business remains competitive in today's dynamic market landscape.

This machine is the most accurate and ideal weighing filling equipment for large drums.Intelligent weighing and feedback system makes the operation without manual adjustment and the filling dose more accurate.The operation is carried out through the touch-screen man-machine interface system: when the filling container reaches the fixed position, the photoelectric control positioner will position the filling head, and the filling head will automatically dive to start the filling.When the filling amount is close to the specified filling parameters, the solenoid valve closes the filling with large flow to small flow to ensure the filling accuracy.

Conveyor belt

When the barrel is placed on it, the conveyor belt takes the barrel into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of barrel,The width between the baffle plates on both sides of the conveyor belt can be adjusted according to your container,ensure smooth barrel safely from the conveyor belt moved .

Filling Head

when the barrel comes under the filling head, cylinder head began to move down the drive filling, filling process without dripping, do not waste material, also can ensure the barrel clean and tidy.

The size of the filling head can be customized according to the caliber of the barrel, ensuring that this machine is absolutely suitable for your product

In addition to,If you're looking for Barrel Filling Machine,automatic barrel filling machine,it is a pleasure for you to visit our website anytime

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.