- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

In the pharmaceutical manufacturing landscape, where precision and efficiency are paramount, the Liquid Vial Filling Machine emerges as a game-changer. Seamlessly integrating cutting-edge technology with meticulous craftsmanship, this innovative device offers pharmaceutical producers a reliable solution for filling liquid vials with precision and speed. Let's delve into the unique characteristics, versatile applications, and intricate mechanical principles of this transformative equipment reshaping the pharmaceutical industry.

Product Characteristics:

The Liquid Vial Filling Machine boasts an array of exceptional features meticulously engineered for precise and efficient filling. Crafted from durable materials, such as stainless steel, it ensures longevity and adherence to the highest quality standards. Equipped with advanced dosing systems, customizable settings, and user-friendly interfaces, this machine provides seamless automation while retaining control over the filling process. Its adjustable controls accommodate various liquid viscosities, guaranteeing consistent and accurate fills for each vial. With anti-drip mechanisms and secure sealing, it preserves the integrity of pharmaceutical formulations, delivering products of unparalleled quality and reliability.

Product Applications:

The applications of the Liquid Vial Filling Machine cater to the diverse needs of pharmaceutical formulations. Ideal for medium to large-scale production, it excels in filling liquid vials with precision, whether for vaccines, injectables, or other pharmaceutical solutions. Pharmaceutical manufacturers leverage its versatility for custom formulations, ensuring each vial receives a precise and uniform fill. Whether dispensing lifesaving medications or specialized treatments, the Liquid Vial Filling Machine serves as an indispensable tool for achieving pharmaceutical excellence with finesse.

Mechanical Principle:

At its core, the Liquid Vial Filling Machine operates on advanced mechanical principles designed for precision and adaptability. Utilizing automated dosing pumps, conveyor systems, and precision filling nozzles, it accurately measures and dispenses precise quantities of liquid pharmaceuticals into individual vials. Temperature controls maintain optimal consistency, while integrated sensors and programmable logic controllers oversee the automated process. This precision ensures uniformity, minimizing errors and maximizing efficiency while upholding the stringent quality standards of pharmaceutical production.

In conclusion, the Liquid Vial Filling Machine represents the epitome of synergy between technology and pharmaceutical craftsmanship. Its exceptional characteristics, diverse applications, and balanced mechanical principles make it an indispensable asset for pharmaceutical producers seeking the perfect blend of precision, efficiency, and reliability. As a cornerstone of pharmaceutical manufacturing, it continues to redefine industry standards, ensuring each liquid vial embodies the essence of precision, safety, and pharmaceutical excellence.

This filling capping machine is suitable for:

A variety of small doses of liquid filling & capping such as oil, injection. Widely used in food, pharmaceutical, chemical industries and scientific research.

This machine function is:

1. Automatic conveyor belt running

2. Automatic bottles feeding

3. Automatic rubber plug feeding and loading

4. Automatic aluminum Caps capping

5. Automatic double filling heads and filling

6. No bottles no filling

7. No bottles no plug

8. No bottles no capping

9. Can be customized according to different bottles shape and size

Characteristic:

1、 Human-machine interface settings, an easy and intuitive, PLC control, the amount of precision equipment.

2、 Frequency control, the production rate be adjusted automatically count.

3、 No bottle no filling.

4、 SUS304 and 316L stainless steel, full compliance with GMP requirements.

This machine is built in the absorption of foreign advanced technology, based on independently developed by our company.

Full compliance with the GMP requirements.

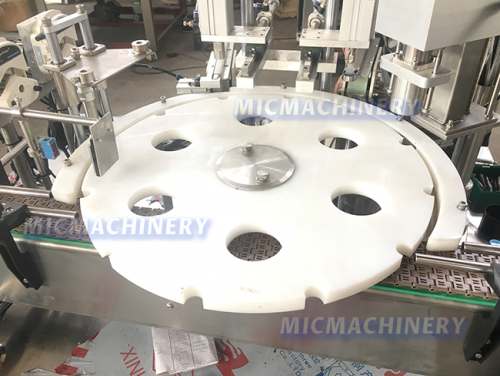

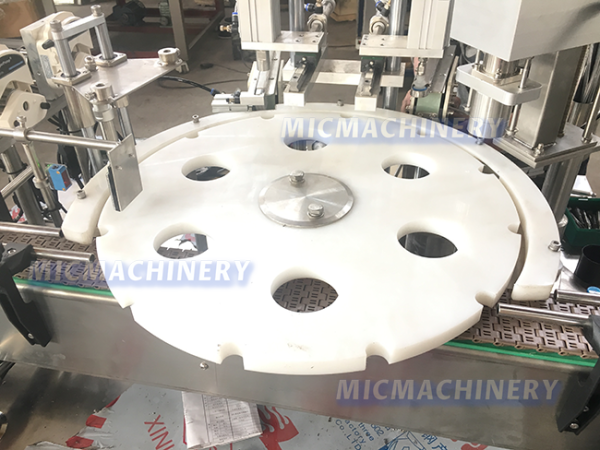

The main platform

The picture includes chuck, sensor.filling head,and automatic plug feeding and lid tightening stations.They are clear function and easy to clean.

Among them, the chuck is used to fix the filling container and drive the container to move to the filling、capping and other stations. The circular design can save space while setting up multiple positions, so that the filling process is time-saving and efficient

We can customize this turntable, filling head, screw cap and so on

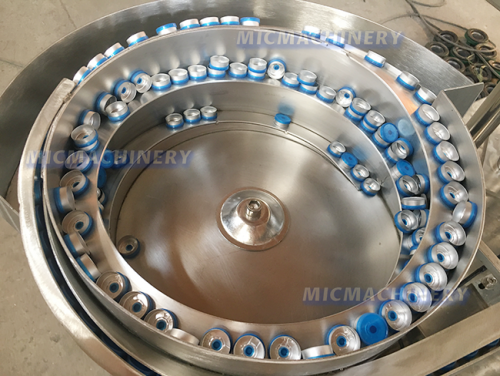

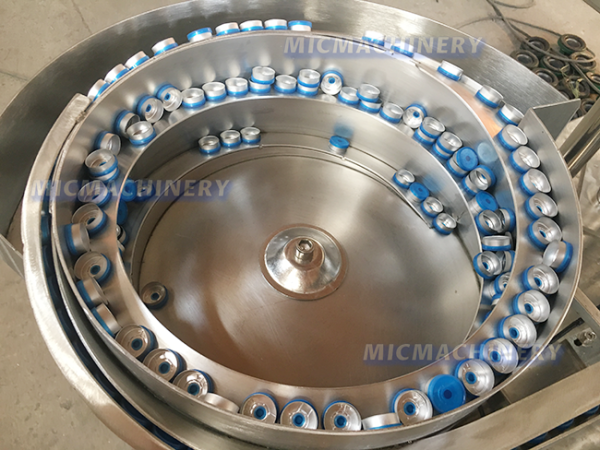

outside cover loading automatically

outside cover feeding cage with vibrating disk is connected to a pipe that carries the outside cover ,They automatically arranges the outside cover and deliver the outside cover.

In this way, the small bottle is covered in a consistent process, reducing the manual contact with the syringe process, and ensuring bottle hygiene,At the same time, labor costs are reduced.

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of bottle,The width between the two pipes can be adjusted according to your container,ensure smooth bottle safely from the conveyor belt moved .

on the side of the conveyor is equipped with sensors that can automatically identify when the bottle to go out or, in order to send signals to filling station of screw cap

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback:

|

Filling volume |

5-50ml |

|

Loading error |

≤ ±1% |

|

Rotation (rolling) Cover pass rate |

≥99% |

| Production capacity |

30-50BPM |

|

60-90BPM |

|

|

Power supply |

380V/50Hz |

|

Power |

2.0 kw |

|

Weight |

600 kg |

|

Dimension |

2000*1000*1500mm |

|

Name |

Brand |

|

Press-button |

Schneider |

|

Magnetic Contactor |

Schneider |

|

Relay |

Omron |

|

Frequency Transformer |

Mitsubishi |

|

Motor |

JSCC made in Germany |

|

Air Cylinder |

Airtac |

|

Solenoid Valve |

Airtac |

|

Speed Reducer |

Made in Taiwan |

|

Bearing |

NSK |

|

PLC |

Mitsubishi |

|

Touch Screen |

Mitsubishi |

|

Fibre-optical |

Autonics |

|

Switching Mode Power Supply |

NWELL |

|

Step Motor |

SNAYO made in Japan |

- Vial Filling Machine ( 7000-24000 pcs/h )

- Vial Liquid Filling Machine ( 130 bottles/min )

- Small Vial Filling Machine ( 200 Bottles/min )

- Automatic Vial Filling Machine ( 20-30 Bottles/min )

- Liquid Vial Filling Machine ( 30-90 bottles/min )

- Spray vial filling line(30-150 Bottles/min)

- Sterile Vial Filling Machine(60-600 Bottles/min)

- Vial Filling Machine(30-200 Bottles/min)

- Automatic Vial Filling Machine(16 large-dose tracking 30-150 Bottles/min)

- Vial Filling Equipment ( 20-40 Bottles/min )

- Vial Filling And Capping Machine ( 20-40 Bottles/min )

- Vial Filler ( 20-30 Bottles/min )

- High Speed Vial Filling Machine(16 Heads 30-450 Bottles/min)

- Plastic Vial Filling Machine

- Powder Vial Filling Machine