- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

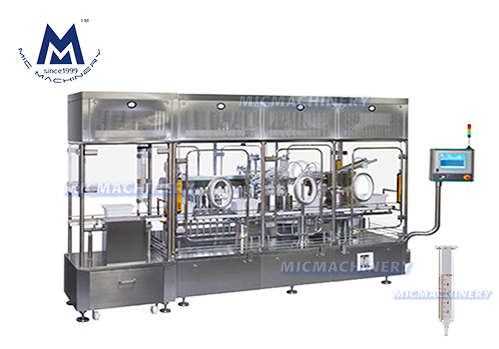

In the dynamic landscape of medical manufacturing, precision and efficiency intertwine with the Syringe Filling Machine. This advanced apparatus seamlessly blends technological prowess with industrial precision, offering medical device manufacturers a streamlined solution for filling syringes with accuracy and speed. Let's explore the distinctive features, versatile applications, and intricate operational principles of this transformative device revolutionizing the medical industry.

Product Characteristics:

The Syringe Filling Machine showcases a plethora of exceptional features meticulously engineered for precise and efficient filling. Crafted from high-grade materials, including stainless steel and precision components, it ensures durability and adherence to rigorous quality standards. Equipped with automated dosing systems, customizable settings, and intuitive interfaces, this machine delivers seamless automation while maintaining control over the filling process. Its adjustable controls accommodate a wide range of syringe sizes and viscosities, ensuring consistent and accurate fills for each medical device. With anti-drip mechanisms and secure sealing, it preserves the integrity of medical formulations, delivering products of unmatched quality and reliability.

Product Applications:

The applications of the Syringe Filling Machine cater to the diverse needs of medical device manufacturing. Ideal for medium to large-scale production, it excels in filling syringes with pharmaceuticals, vaccines, and biologics where precision is paramount. Medical device manufacturers leverage its versatility for custom formulations, ensuring each syringe receives a precise dosage. Whether filling insulin cartridges or administering flu shots, the Syringe Filling Machine serves as an indispensable tool for achieving medical manufacturing excellence with precision and efficiency.

Operational Principle:

At its core, the Syringe Filling Machine operates on advanced mechanical principles designed for precision and adaptability. Utilizing automated dosing pumps, conveyor systems, and precision filling nozzles, it accurately measures and dispenses precise quantities of medical substances into individual syringes. Temperature controls maintain optimal viscosity, while integrated sensors and programmable logic controllers oversee the automated process. This precision ensures uniformity, minimizing errors and maximizing efficiency while upholding the stringent standards of medical manufacturing.

In conclusion, the Syringe Filling Machine represents the pinnacle of synergy between technology and industrial precision in medical device manufacturing. Its exceptional features, versatile applications, and balanced operational principles make it an indispensable asset for medical manufacturers seeking the perfect blend of precision and automation. As a cornerstone of medical device production, it continues to redefine industry standards, ensuring each syringe embodies the essence of accuracy, efficiency, and reliability.

MIC machine persist in their own ideals,remittance is responsible for development,dedicated to the field of prefillable packaging,made a brilliant achievenent After years of effort,general can provide the customer from tube loading &sterile bags removing machine.syringe nest off machine.syringe filling and closing machinge.visual inspection machine,toplunger rod screwing and labelingmachine a complere set of pre-filled syring packaging line equipment.

Product covers vacuum.liquid filling .laboratory series.more than ten varieties.fine details.stable performance won reputation.

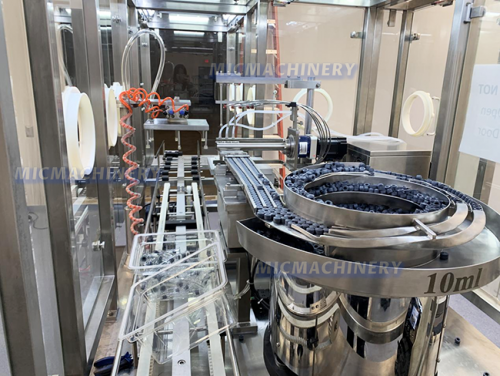

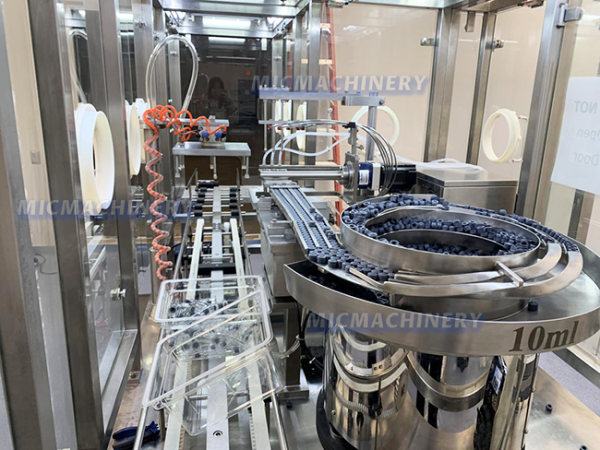

Syringe container filling head

The syringes are arranged neatly in the matching slot, and the filling starts row by row when they reach the designated position. This machine can ensure accurate filling and no drip leakage. Accurate filling during the filling process, reliable and accurate line by line movement.

Inside plug loading automatically

Inside plug feeding cage with vibrating disk is connected to a pipe that carries the Inside plug ,They automatically arranges the Inside plug and deliver the Inside plug.

In this way, the syringe is covered in a consistent process, reducing the manual contact with the syringe process, and ensuring syringe hygiene,At the same time, labor costs are reduced

cap station

vacuum cap to avoido air bubbles inside

If you want to know more models of filling machine, you can refer to the table below:

|

Syringe Filling Machine |

||||

|

model |

SGJ |

SGJ-1 |

SGJ-2 |

SGJ-3 |

|

application |

medicine, chemistry, biology,etc |

|||

|

Packing type |

various syringes, boosters, injection tubes,etc |

|||

|

speed |

5000pcs/h |

20-30pcs/min |

800-1000pcs/h |

800-1000pcs/h |

|

Filling arrange |

0.5-50ML |

5-100ML |

0.5-50ML |

0.5-50ML |

|

power |

3.5KW |

2KW |

2KW |

2KW |

|

size |

2500*1350*1600mm |

1380*1030*1800mm |

1800*800*1700mm |

1800*800*1700mm |

|

weight |

1500KG |

390KG |

450KG |

450KG |

In addition to,If you're looking for syringe filling machine,pre filled syringe filling machine manufacturers,syringe filling equipment,pfs filling machine,automatic syringe filler,syringe filling machine manufacturer,automatic syringe filling machine,syringe filling machine manufacturers,prefilled syringe filling machine,prefilled syringe machine,oral syringe filling machine,aseptic syringe filling equipment,sterile syringe filling machine,prefilled syringe machine manufacturers,syringe filling machine price.You can browse our product website more.

If you are more than interested in the machine ,you can contact us at market@micmachinery.com

|

Weight |

1500KG |

|

Voltage |

220V 50Hz |

|

Filling range |

0.5-50ml |

|

Air supply |

0.6Mpa |

|

Dimension |

2500*1350*1600mm |

|

Power |

3.5KW |

|

Filling speed |

5000pieces/hour |

|

Air consumption |

10 m ³ /h |

- MIC Syringe Filling Machine ( 5000 Syringes/h )

- MIC Prefilled Syringe Filling Machine ( 5000 Syringes/h )

- MIC Pre Filled Syringe Filling Machine Manufacturers ( 800-1500 Syringes/h )

- MIC Aseptic Syringe Filling Equipment ( 2000 Syringes/h )

- MIC Prefilled Syringe Machine ( 2000-3500 Syringes/h )

- MIC Automatic Syringe Filler ( 200-1200 Bottles/h )

- MIC-SGJ1 Syringe Filling Equipment ( 20-30 Syringes/min )

- MIC Automatic Syringe Filling Machine ( 3000 Syringes/h )

- MIC Pfs Filling Machine ( 10-30 Syringes/min )