- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

In the dynamic landscape of pharmaceutical manufacturing, precision and efficiency are indispensable, and the Prefilled Syringe Machine emerges as a pivotal innovation. Seamlessly integrating advanced technology with meticulous craftsmanship, this cutting-edge device offers pharmaceutical companies a reliable solution for automating the production of prefilled syringes with precision and speed. Let's delve into the distinctive characteristics, versatile applications, and intricate mechanical principles of this transformative tool reshaping the pharmaceutical industry.

Product Characteristics:

The Prefilled Syringe Machine boasts a myriad of exceptional features meticulously engineered for precise and efficient production. Crafted from premium materials, such as stainless steel, it ensures durability and adherence to stringent quality standards. Equipped with fully automated dosing systems, customizable settings, and user-friendly interfaces, this machine provides seamless automation while retaining control over the manufacturing process. Its adjustable controls accommodate various pharmaceutical formulations, guaranteeing consistent and accurate fills for each prefilled syringe. With anti-drip mechanisms and secure sealing, it upholds the integrity of pharmaceutical products, delivering solutions of unparalleled quality and reliability.

Product Applications:

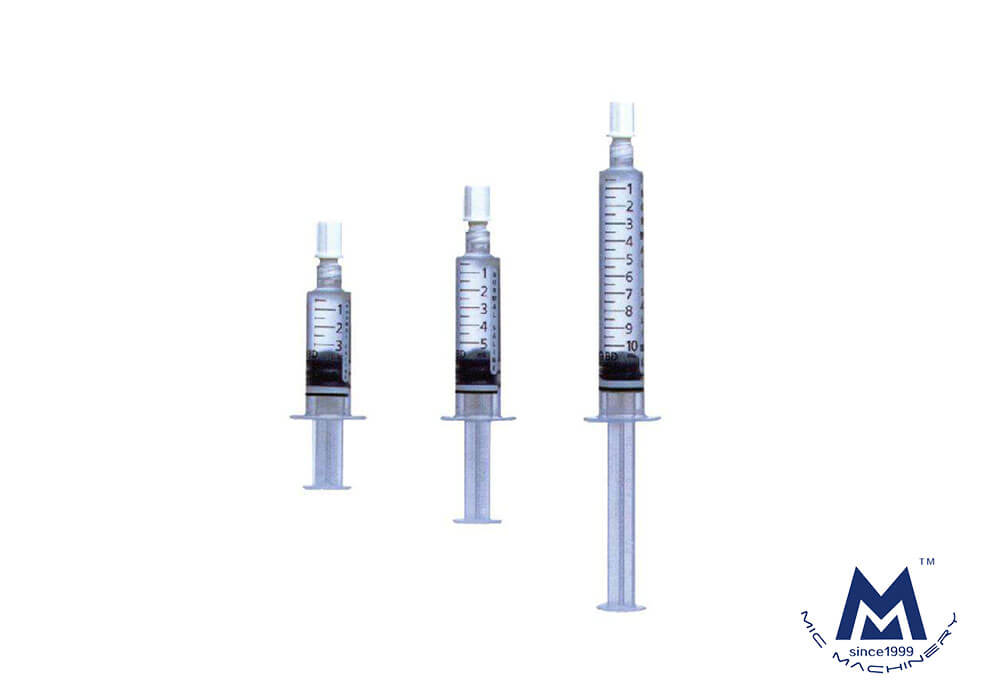

The applications of the Prefilled Syringe Machine cater to the diverse needs of pharmaceutical formulations. Ideal for medium to large-scale production, it excels in manufacturing prefilled syringes with precision and efficiency. Pharmaceutical companies leverage its versatility for custom formulations, ensuring each prefilled syringe meets rigorous quality and safety standards. Whether delivering vaccines, biologics, or injectable medications, the Prefilled Syringe Machine serves as an indispensable tool for achieving pharmaceutical excellence with finesse.

Mechanical Principle:

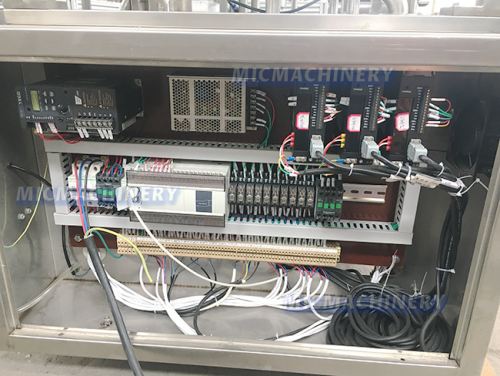

At its core, the Prefilled Syringe Machine operates on advanced mechanical principles designed for precision and adaptability. Utilizing fully automated dosing pumps, conveyor systems, and precision filling mechanisms, it accurately measures and dispenses precise quantities of pharmaceutical solutions into individual prefilled syringes. Temperature controls maintain optimal consistency, while integrated sensors and programmable logic controllers oversee the fully automated process. This precision ensures uniformity, minimizing errors and maximizing efficiency while upholding the highest standards of pharmaceutical manufacturing.

In conclusion, the Prefilled Syringe Machine represents the epitome of synergy between technology and pharmaceutical expertise. Its exceptional characteristics, diverse applications, and balanced mechanical principles make it an indispensable asset for pharmaceutical companies seeking the perfect blend of precision and automation. As a cornerstone of pharmaceutical production, it continues to redefine industry standards, ensuring each prefilled syringe embodies the essence of precision, efficiency, and pharmaceutical excellence.

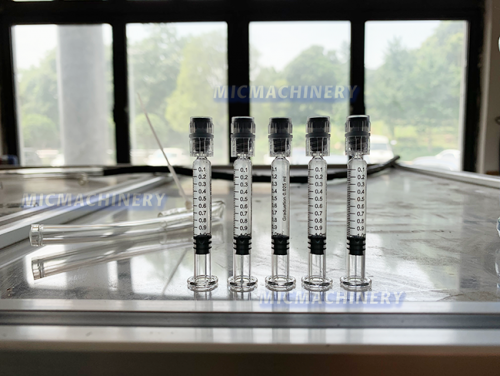

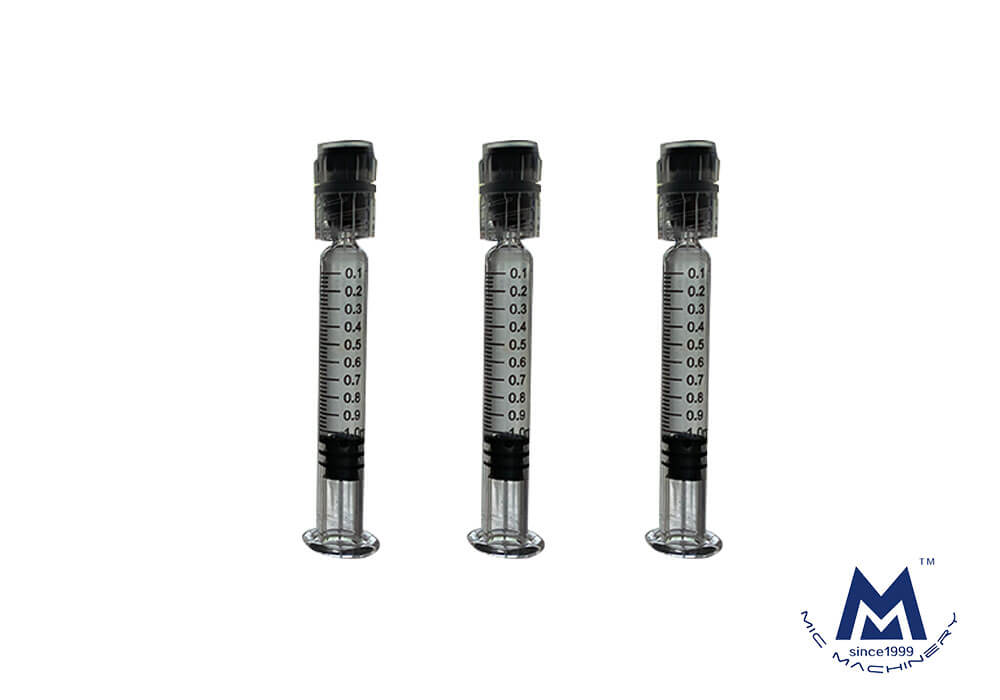

Accurately fill and control bubbles when plugging. Automatic operation, full monitoring. In addition to normal liquids, it is also suitable for filling prefilled,oral,aseptic syringe.

5 synovial fluid filling nozzle. 4 sets of servo motors (Jingchuan, Japan), accurate filling and plugging in the filling process, reliable and accurate line-by-line movement.

S/S rotary pump. Filling volume settings and precision adjustments operate on the touch screen without any tools.

Siemens color touch screen. Real-time monitoring and display of various operating conditions, vacuum pressure, nitrogen pressure, C/A pressure, fault alarm and position indication, fault indication and recording. Multi-language display.

Use MVS (Machine Vision System) to monitor plug quality to ensure greater acceptability (optional).

Process parameters can be printed, stored and retrieved in a timely manner.

All contact parts are made of SUS316L and medical silicone rubber. The machine is coated with SUS304 and 6061 oxidized aluminum alloy.

The main platform and control panel

The picture includes chuck, filling head,and automatic plug feeding stations and control.They are clear function and easy to clean.

Among them, the chuck is used to fix the filling container and drive the container to move to the filling、plugging. The circular design can save space while setting up multiple positions, so that the filling process is time-saving and efficient

We can customize this turntable, filling head, screw cap and so on

Automatic plugging system

The automatic plug feeding system arranges the soft plugs and the soft plugs are arranged neatly into the plugging position. When the syringe reaches the specified position after filling, the servo motor drives to insert the soft plug accurately, with vacuum seal and no bubbles

|

Syringe Filling Machine |

||||

|

model |

SGJ |

SGJ-1 |

SGJ-2 |

SGJ-3 |

|

application |

medicine, chemistry, biology,etc |

|||

|

Packing type |

various syringes, boosters, injection tubes,etc |

|||

|

speed |

5000pcs/h |

20-30pcs/min |

800-1000pcs/h |

800-1000pcs/h |

|

Filling arrange |

0.5-50ML |

5-100ML |

0.5-50ML |

0.5-50ML |

|

power |

3.5KW |

2KW |

2KW |

2KW |

|

size |

2500*1350*1600mm |

1380*1030*1800mm |

1800*800*1700mm |

1800*800*1700mm |

|

weight |

1500KG |

390KG |

450KG |

450KG |

In addition to,If you're looking for syringe filling machine,pre filled syringe filling machine manufacturers,syringe filling equipment,pfs filling machine,automatic syringe filler,syringe filling machine manufacturer,automatic syringe filling machine,syringe filling machine manufacturers,prefilled syringe filling machine,prefilled syringe machine,oral syringe filling machine,aseptic syringe filling equipment,sterile syringe filling machine,prefilled syringe machine manufacturers,syringe filling machine price.You can browse our product website more.

If you are more than interested in the machine ,you can contact us at market@micmachinery.com

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Production capacity |

2000-3500 syringes / hour |

|

Filling amount |

0.1-0.5ml, 0.5-3ml, 3-10ml, 10-30ml |

|

Machine vision system resolution (optional) |

752*480dpi |

|

Vacuum degree |

0-98kpa (0-750mmHg) |

|

Nitrogen |

1kg/cm2, 0.1m3/min, 0.25U |

|

Compressed air |

6kg/cm m2, 0.35m m2/min |

|

Power supply |

380V/220V, 50-60Hz, 5.5KW, 3P (including vacuum pump) |

|

Size |

3050x1600x1900mm (length x width x height) |

|

Machine weight |

950kg |

|

Touch screen |

Siemens |

PLC |

Siemens |

|

Button |

Schneider |

Power switch |

Omron |

|

Air switch |

Schneider |

Intermediate relay |

Schneider |

| Optoelectronic switch |

Germany sick |

Proximity switch |

Pefun |

|

Air cylinder |

Taiwan AirTAC |

Solenoid valve |

Taiwan AirTAC |

|

Encoder |

Japan Koyo |

Main motor |

Wuxi Qipeng |

|

Bearing |

Germany FAG |

Rack |

SUS304 |

- MIC Syringe Filling Machine ( 5000 Syringes/h )

- MIC Prefilled Syringe Filling Machine ( 5000 Syringes/h )

- MIC Pre Filled Syringe Filling Machine Manufacturers ( 800-1500 Syringes/h )

- MIC Aseptic Syringe Filling Equipment ( 2000 Syringes/h )

- MIC Prefilled Syringe Machine ( 2000-3500 Syringes/h )

- MIC Automatic Syringe Filler ( 200-1200 Bottles/h )

- MIC-SGJ1 Syringe Filling Equipment ( 20-30 Syringes/min )

- MIC Automatic Syringe Filling Machine ( 3000 Syringes/h )

- MIC Pfs Filling Machine ( 10-30 Syringes/min )