- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

In the realm of medical manufacturing, precision and efficiency converge with the Automatic Syringe Filling Machine. This state-of-the-art innovation seamlessly combines advanced technology with meticulous craftsmanship, providing medical device manufacturers with a reliable solution for automating the filling of syringes with accuracy and efficiency. Let's delve into the unique characteristics, versatile applications, and intricate mechanical principles of this transformative device reshaping the medical industry.

Product Characteristics:

The Automatic Syringe Filling Machine boasts an array of exceptional features meticulously engineered for precise and efficient filling. Crafted from high-quality materials, such as stainless steel, it ensures durability and adherence to stringent quality standards. Equipped with fully automated dosing systems, customizable settings, and intuitive interfaces, this machine provides seamless automation while retaining control over the filling process. Its adjustable controls accommodate various medical viscosities, guaranteeing consistent and accurate fills for each syringe. With anti-drip mechanisms and secure sealing, it safeguards the integrity of medical formulations, delivering products of unparalleled quality and reliability.

Product Applications:

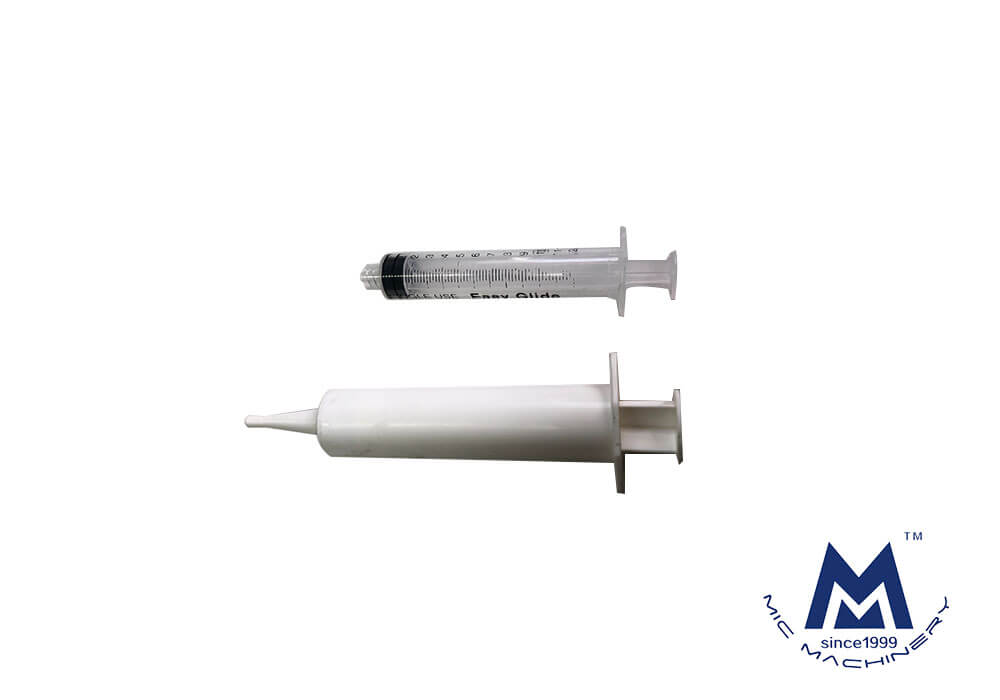

The applications of the Automatic Syringe Filling Machine cater to the diverse needs of medical device manufacturers. Ideal for medium to large-scale production, it excels in filling syringes with precision and efficiency. Medical companies leverage its versatility for custom formulations, ensuring each syringe meets the highest standards of quality and safety. Whether delivering vaccines, medications, or diagnostic agents, the Automatic Syringe Filling Machine serves as an indispensable tool for achieving medical manufacturing excellence with finesse.

Mechanical Principle:

At its core, the Automatic Syringe Filling Machine operates on advanced mechanical principles designed for precision and adaptability. Utilizing fully automated dosing pumps, conveyor systems, and precision filling nozzles, it accurately measures and dispenses precise quantities of medical solutions into individual syringes. Temperature controls maintain optimal consistency, while integrated sensors and programmable logic controllers oversee the fully automated process. This precision ensures uniformity, minimizing errors and maximizing efficiency while upholding the highest standards of medical device manufacturing.

In conclusion, the Automatic Syringe Filling Machine represents the pinnacle of synergy between technology and medical expertise. Its exceptional characteristics, diverse applications, and balanced mechanical principles make it an indispensable asset for medical device manufacturers seeking the perfect blend of precision and automation. As a cornerstone of medical manufacturing, it continues to redefine industry standards, ensuring each syringe embodies the essence of precision, efficiency, and medical excellence.

This machine suits for the plastic,prefilled,oral,aseptic syringe.syringe and can fill many kinds of liquid,gel or paste.

Working progress:

Adopt cap sorter to sort the syringe(the pusher has been placed in the syringe and pushed to the bottom.).Then it will transfer the syringe to the main working station by rotary wheel.

About the filling station:

Filling by ceramic filling pump,Filling nozzle will sealed the tip of the syringe from the bottom to top by pressure filling,the piston movement will drive by the servo motor,filling volume and speed both can set and adjust on the touch screen.

About the Capping station:

The cap will transfer to the bottom of the syringe by vibrating disk, and then the cap is driven upward by the cylinder

Discharge:

The dial wheel rotates to the discharge station, and the syringe is pulled down from the dial by the discharge lever, and then the slide is slid down to collect (single slide down).

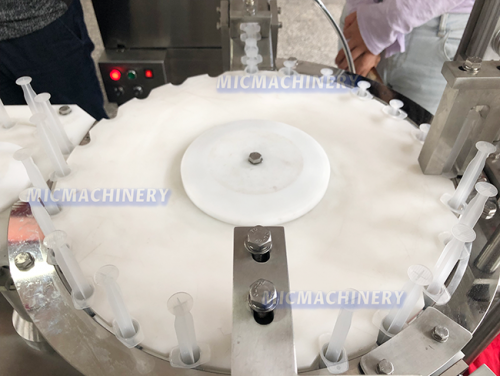

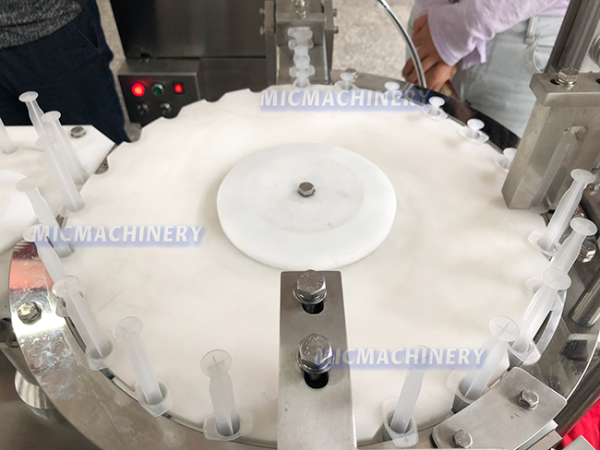

The main platform

The picture includes chuck, filling head,and automatic syinge feeding and syinge piston feeding stations.They are clear function and easy to clean.

Among them, the chuck is used to fix the filling container and drive the container to move to the filling、capping. The circular design can save space while setting up multiple positions, so that the filling process is time-saving and efficient

We can customize this turntable, filling head, screw cap and so on

Automatic cap feeding system

cap feeding cage with vibrating pate is connected to a pipe that carries the syinge' cap ,They automatically arranges the cap and deliver the cap into the filling machine

In this way, reducing the manual contact with the cap, and ensuring syinge hygiene,At the same time, labor costs are reduced

If you want to know more models of filling machine, you can refer to the table below:

|

Syringe Filling Machine |

||||

|

model |

SGJ |

SGJ-1 |

SGJ-2 |

SGJ-3 |

|

application |

medicine, chemistry, biology,etc |

|||

|

Packing type |

various syringes, boosters, injection tubes,etc |

|||

|

speed |

5000pcs/h |

20-30pcs/min |

800-1000pcs/h |

800-1000pcs/h |

|

Filling arrange |

0.5-50ML |

5-100ML |

0.5-50ML |

0.5-50ML |

|

power |

3.5KW |

2KW |

2KW |

2KW |

|

size |

2500*1350*1600mm |

1380*1030*1800mm |

1800*800*1700mm |

1800*800*1700mm |

|

weight |

1500KG |

390KG |

450KG |

450KG |

In addition to,If you're looking for syringe filling machine,pre filled syringe filling machine manufacturers,syringe filling equipment,pfs filling machine,automatic syringe filler,syringe filling machine manufacturer,automatic syringe filling machine,syringe filling machine manufacturers,prefilled syringe filling machine,prefilled syringe machine,oral syringe filling machine,aseptic syringe filling equipment,sterile syringe filling machine,prefilled syringe machine manufacturers,syringe filling machine price.You can browse our product website more.

If you are more than interested in the machine ,you can contact us at market@micmachinery.com

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Voltage |

220V 50Hz |

|

Motor Power |

2KW |

|

Filling speed |

3000pieces/hour |

|

Filling accuracy |

+-1% |

|

Filling volume |

5-50ml |

|

Material tank |

20L(SUS 316) |

|

Air supply |

0.6Mpa |

|

Air consumption |

10 m³/h |

|

Filling nozzle |

1 |

|

Plugging nozzle |

1 |

|

Touch screen |

Proface(Japan) |

|

PLC |

Mitsubshi( Japan) |

|

Frequency converter |

Danfoss(Denmark) |

|

Servo motor |

Dorna |

|

High precision ball screw |

ABBA(Taiwan) |

|

Filling pump |

Ceramic filling pump(customized for gel) |

|

Switching power |

Mean Well(Taiwan) |

|

Pneumatic element |

SNS |

|

Photoelectric detection switch |

Autonics(Korea) |

|

Proximity switch |

Alif(Taiwan) |

|

Machine surface |

SUS 304 |

|

Filling nozzle |

SUS316 |

- MIC Syringe Filling Machine ( 5000 Syringes/h )

- MIC Prefilled Syringe Filling Machine ( 5000 Syringes/h )

- MIC Pre Filled Syringe Filling Machine Manufacturers ( 800-1500 Syringes/h )

- MIC Aseptic Syringe Filling Equipment ( 2000 Syringes/h )

- MIC Prefilled Syringe Machine ( 2000-3500 Syringes/h )

- MIC Automatic Syringe Filler ( 200-1200 Bottles/h )

- MIC-SGJ1 Syringe Filling Equipment ( 20-30 Syringes/min )

- MIC Automatic Syringe Filling Machine ( 3000 Syringes/h )

- MIC Pfs Filling Machine ( 10-30 Syringes/min )