- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the realm of modern coffee culture, where convenience meets the art of brewing, the Coffee Capsule Filling Machine emerges as a game-changing innovation. This cutting-edge device harmoniously blends technology with the nuanced craft of coffee making, redefining how coffee enthusiasts enjoy their favorite blends. By exploring its unique product characteristics, diverse applications, and the intricate mechanical principles guiding its operation, one can truly understand its pivotal role in the coffee industry. From busy households to trendy cafes, this machine ensures that every coffee capsule encapsulates the essence of freshly brewed perfection.

Product Characteristics:

The Coffee Capsule Filling Machine is distinguished by its exceptional product characteristics. Crafted from high-quality materials, these machines are designed for precision and durability, ensuring consistent performance even under high-volume demands. Their adaptability shines through in customizable filling options, accommodating various capsule sizes and coffee blends, catering to the diverse tastes of consumers. Equipped with state-of-the-art dosing systems, these machines ensure accurate filling, minimizing wastage and maximizing the quality of each capsule. Leak-proof seals and aroma-preserving mechanisms maintain the freshness and flavor of the coffee, delivering an exceptional coffee experience to enthusiasts.

Product Applications:

The applications of the Coffee Capsule Filling Machine are versatile and indispensable within the coffee industry. Homebrewers and coffee aficionados benefit from the machine's ability to create perfectly measured capsules, offering the convenience of cafe-quality coffee at home. Cafes and specialty coffee shops utilize these machines to streamline their brewing process, serving patrons with consistently excellent coffee. Office spaces and hospitality services incorporate these machines, providing employees and guests with a convenient and high-quality coffee experience. Furthermore, coffee producers and retailers leverage these machines to offer a wide range of blends, appealing to the diverse palates of consumers.

Mechanical Principle:

At its core, the Coffee Capsule Filling Machine operates on intricate mechanical principles designed for precision and efficiency. Utilizing advanced pumps, filling heads, and conveyor systems, the machine accurately measures and dispenses the specified quantity of freshly ground coffee into individual capsules. Automated sealing mechanisms, employing advanced technology such as pneumatic or servo-driven systems, secure the capsules, preserving the freshness and aroma of the coffee. Integrated sensors and controllers oversee the entire process, ensuring consistency, minimizing errors, and enhancing the overall efficiency of the capsule filling operation.

In conclusion, the Coffee Capsule Filling Machine represents the epitome of innovation and reliability in the coffee industry. Its exceptional product characteristics, diverse applications, and advanced mechanical principles make it an indispensable asset for businesses and coffee enthusiasts alike. Embracing the latest technological advancements, this machine not only encapsulates the essence of freshly brewed coffee but also ensures that every cup delivers a delightful and aromatic experience, making it an essential component in the ever-evolving world of coffee brewing.

Fully automatic rotary cup filling & sealing machine can auto loading the empty cups, empty cups detecting, auto quantitative filling product into cup, auto loading the aluminum foil seal lids, auto sealing cup, auto discharging the finish product. Base on different mold quantity, its capacity from 1000-3000 cups per hour, suitable for the foods and beverage factory production needs.

1.Made by stainless steel 304 and anodizing aluminum, ensures it can run in bad food factory environment which has damp, steam, oil, acidity, coffee and salt etc.

2.Using high quality imported electrical parts and pneumatic parts which ensures and stable running in long time, reduces the stop and maintenance time.

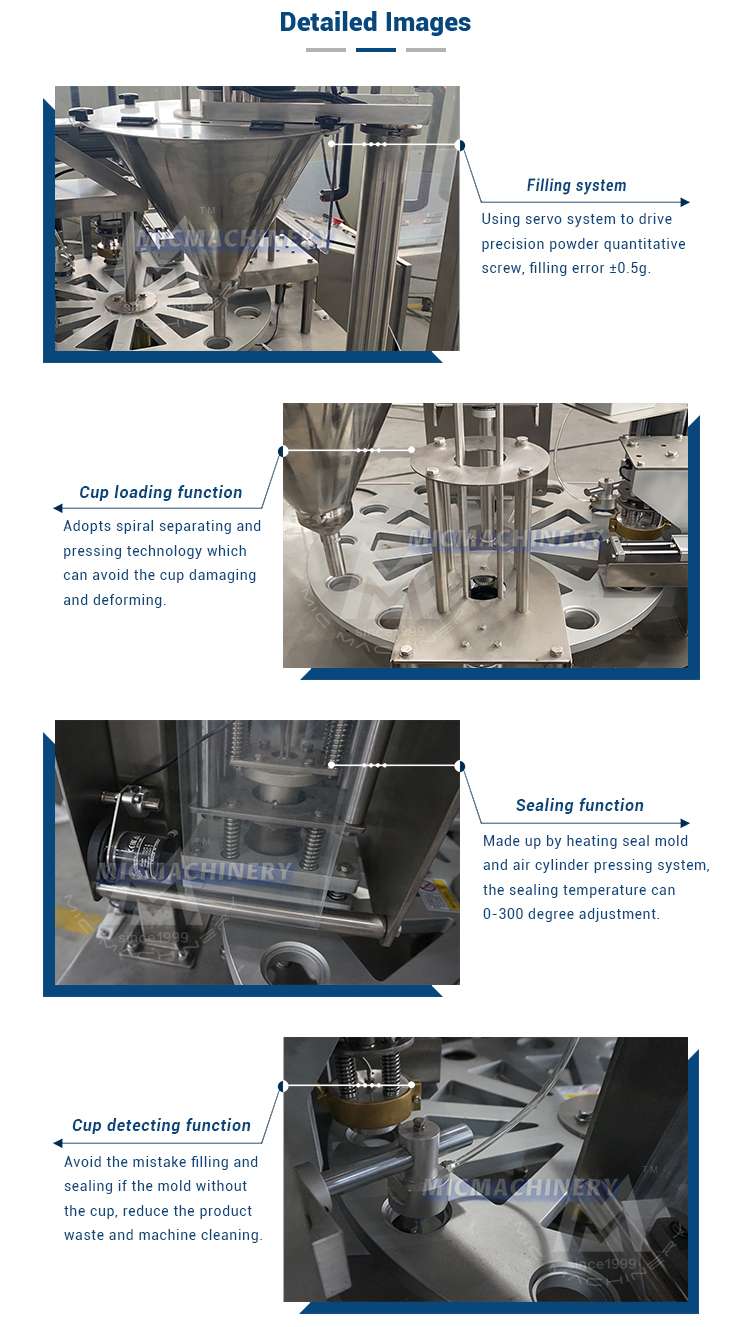

3.Using servo system to drive precision powder quantitative screw, high filling accuracy, reliable operation, easy to adjust.

4.Adopts spiral separating and pressing technology which can avoid the cup damaging and deforming.

5.Has vacuum sucker which can guide the cup to enter into mold accuracy.