High-Performance Emulsifying Mixer Solutions from Micmachinery

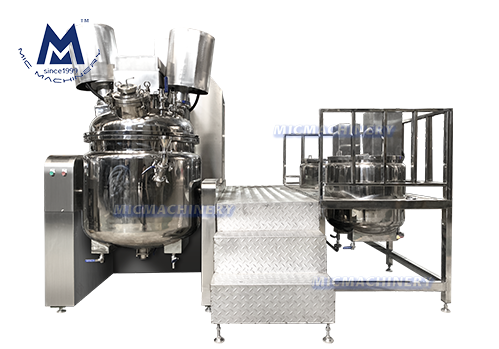

The Emulsifying Machine ensures fast, uniform mixing of liquids, powders, and semi-solids, producing smooth and stable products. Built with stainless steel and precision controls, it meets high hygiene and safety standards.

● High-shear rotor–stator system for ultra-fine particle dispersion

● Adjustable speed and temperature control for different recipes● Easy-to-clean design with CIP (Clean-In-Place) compatibility

The Cosmetic Homogenizer is ideal for creams, lotions, and serums, dispersing active ingredients evenly for premium quality. Its micron-level processing prevents separation and improves shelf life.

● Ideal for creams, lotions, and gels with smooth, luxurious texture

● Micron-level particle reduction for better product stability

● Vacuum option available to remove air bubbles and oxidation

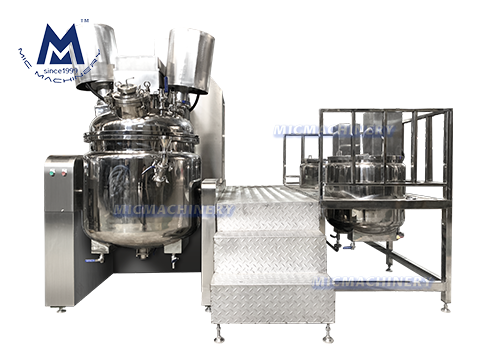

The Vacuum Homogenizer Mixer combines high-shear mixing with vacuum processing to remove air bubbles and prevent oxidation, ensuring dense, smooth, and stable emulsions.

● Vacuum system to eliminate air pockets and improve product density

● Maintains ingredient integrity by preventing oxidation

● Suitable for cosmetics, pharmaceuticals, and food products

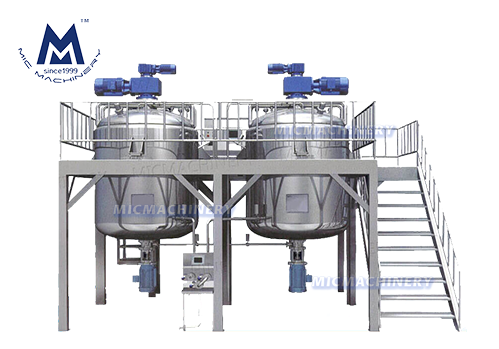

The Emulsifier Machine efficiently blends oil and water phases into long-lasting emulsions with powerful shear forces and flexible controls, suitable for diverse production needs.

● Powerful emulsification for stable, uniform products

● User-friendly controls for easy operation and parameter adjustment

● Durable stainless steel construction for long-term use

Micmachinery provides Emulsifying Machine, Cosmetic Homogenizer, Vacuum Homogenizer Mixer, Emulsifier Machine, and Vacuum Emulsifier Mixer solutions engineered for efficiency, stability, and quality. Our equipment supports a wide range of production needs with consistent results.

Your Reliable Partner in Emulsification Technology

Partnering with Micmachinery means getting advanced equipment, tailored configurations, and expert support. From high-speed Cosmetic Homogenizers to versatile Vacuum Emulsifier Mixers, we deliver long-term value and help you stay competitive.