|

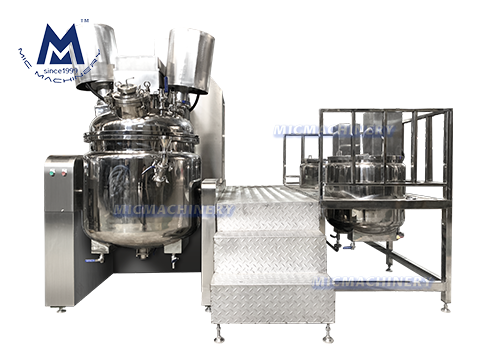

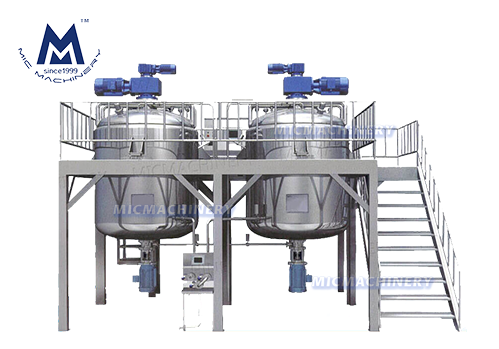

Vacuum Homogenizer Mixer |

|||||||||||

|

Model |

10L |

30L |

50L |

100L |

150L |

200L |

300L |

500L |

600L |

1000L |

|

|

Working Capaicty |

10 |

30 |

50 |

100 |

150 |

200 |

300 |

500 |

600 |

1000 |

|

|

Emulsify |

KW |

0.75 |

1.1 |

2.2 |

3 |

4 |

4 |

4 |

7.5 |

11 |

11 |

|

|

Min/r |

0-2800 |

0-2900 |

0-2800 |

0-2800 |

0-2800 |

0-2800 |

0-2900 |

0-3500 |

0-3500 |

0-3500 |

|

Agitator |

KW |

0.55 |

1.1 |

1.1 |

1.1 |

1.5 |

1.5 |

2.2 |

2.2 |

4 |

4 |

|

|

Min/r |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

|

Machine Dimension |

Length |

1100 |

1650 |

1500 |

1700 |

1100 |

2600 |

1100 |

3000 |

3000 |

4800 |

|

|

Width |

600 |

600 |

600 |

650 |

600 |

1900 |

600 |

2500 |

1300 |

3000 |

|

|

Height |

1500 |

1700-2300 |

1900-2500 |

1700-2700 |

1700-2700 |

2500-3500 |

2500-3500 |

3200-4500 |

3200-4500 |

2500-3850 |

Master Efficient Emulsification with an Emulsifying Machine

Introduction:

In industries where precise emulsification is a critical process, the emulsifying machine takes center stage as a powerful tool. This technical article explores the features, benefits, and applications of emulsifying machines, shedding light on their significance in achieving superior emulsion quality and stability.

Emulsifying Machine:

An emulsifying machine is a specialized piece of equipment designed to facilitate the emulsification process. This machine utilizes mechanical force and shear to break down larger droplets and disperse them uniformly throughout the mixture. With precise control over parameters such as speed, temperature, and mixing time, the emulsifying machine ensures efficient and consistent emulsification in various industries, including cosmetics, food, pharmaceuticals, and chemicals.

Emulsifying Mixer Machine:

An emulsifying mixer machine combines the functions of mixing and emulsifying in a single device. This versatile machine offers efficient blending of two or more immiscible liquids, resulting in stable and homogeneous emulsions. With adjustable speed settings, temperature control, and advanced mixing technologies, the emulsifying mixer machine enables manufacturers to achieve optimal emulsion quality and consistency in their products.

Emulsifying Mixer:

An emulsifying mixer is a key component of emulsion production processes. This machine operates by subjecting the mixture to intense shear forces, effectively breaking down large droplets and promoting the dispersion of immiscible liquids. The emulsifying mixer ensures uniformity, stability, and superior texture in emulsion-based products, making it an essential tool in industries that require precise control over emulsification.

Vacuum Emulsifying Machine:

A vacuum emulsifying machine takes emulsion production to the next level by incorporating a vacuum system into the emulsification process. This machine eliminates air bubbles and reduces oxidation, resulting in emulsions with improved stability, extended shelf life, and enhanced product integrity. The vacuum emulsifying machine finds wide application in industries such as cosmetics, pharmaceuticals, and food manufacturing.

Vacuum Emulsifying Mixer Machine:

The vacuum emulsifying mixer machine combines the benefits of a vacuum system with efficient mixing and emulsifying capabilities. This advanced machine operates under reduced pressure conditions, ensuring the elimination of air bubbles and enhanced emulsion stability. The vacuum emulsifying mixer machine offers precise control over emulsification parameters, resulting in consistent and high-quality emulsions for industries requiring superior product performance.

Vacuum Emulsifying Mixer Price:

The price of a vacuum emulsifying mixer can vary depending on factors such as capacity, features, and the manufacturer. Factors like the quality of materials used, technological advancements, and additional functionalities also impact the price. It's advisable for buyers to consider their specific requirements and budget while comparing prices from reputable manufacturers to make an informed decision.

Vacuum Emulsifying Mixer:

A vacuum emulsifying mixer is a versatile and high-performance machine used in emulsion production. By operating under vacuum conditions, this mixer minimizes air entrapment and ensures the production of stable and uniform emulsions. The vacuum emulsifying mixer is commonly used in industries such as cosmetics, pharmaceuticals, and food, where precise control over emulsion quality and stability is crucial.

Conclusion:

Emulsifying machines play a vital role in achieving efficient and precise emulsification processes across various industries. Whether it's an emulsifying machine, emulsifying mixer machine, or vacuum emulsifying machine, these advanced devices enable manufacturers to produce stable and high-quality emulsions. By incorporating these machines into their production processes, industries can achieve superior emulsion performance, enhanced product stability, and a competitive edge in the market.