- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

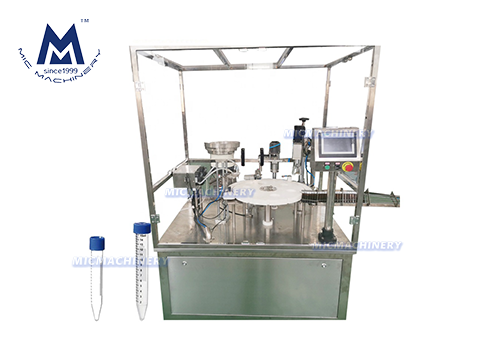

In the critical landscape of vaccine manufacturing, precision, and efficiency are paramount to uphold the safety and efficacy of medical products. The 15ml Tube Vaccine Filling Machine stands as a crucial component, offering meticulous and automated filling for vaccine tubes. Let's delve into how this equipment performs, focusing on its role as a vaccine filling machine, automatic vaccine filling machine, and vaccine packing machine.

Maximizing Performance with 15ml Tube Vaccine Filling Machine

Accurate Filling Precision: The 15ml Tube Vaccine Filling Machine guarantees precise and consistent filling of vaccine tubes. Equipped with advanced dosing mechanisms and controls, this equipment delivers uniform filling levels, ensuring dosage accuracy crucial for vaccine potency and patient safety.

Efficient Production Process: Serving as an automatic vaccine filling machine, this equipment streamlines vaccine production by automating the filling process. Its automated features, including dosage adjustments and tube handling, minimize human intervention, reduce errors, and increase production throughput, thereby optimizing efficiency.

Reliable and Versatile Operation: As a vaccine packing machine, the 15ml Tube Vaccine Filling Machine offers reliability and versatility. Its adaptable design accommodates various tube sizes and configurations, catering to diverse vaccine packaging requirements while maintaining consistent performance levels.

Serving as a Vaccine Filling Machine, Automatic Vaccine Filling Machine, and Vaccine Packing Machine

Vaccine Filling Machine: The 15ml Tube Vaccine Filling Machine serves as a specialized solution for accurately filling vaccine tubes. Its robust construction and precise engineering ensure accurate dosing, critical for maintaining vaccine potency and ensuring patient safety.

Automatic Vaccine Filling Machine: Tailored specifically for vaccine manufacturing, this equipment automates the filling process, optimizing efficiency and reducing the risk of contamination. Its automated features, such as sterile filling and sealing, adhere to stringent regulatory standards, ensuring product integrity and compliance.

Vaccine Packing Machine: With its comprehensive capabilities, the 15ml Tube Vaccine Filling Machine facilitates efficient vaccine packing. Whether filling single-dose tubes or multi-dose packages, this equipment ensures proper sealing and labeling, essential for vaccine distribution and administration.

Conclusion

The 15ml Tube Vaccine Filling Machine plays a pivotal role in vaccine production, ensuring precision, efficiency, and adherence to regulatory standards. Whether serving as a vaccine filling machine, automatic vaccine filling machine, or vaccine packing machine, it contributes to the timely and safe delivery of critical medical products. By investing in this advanced equipment, manufacturers can streamline vaccine manufacturing processes, enhance product quality, and ultimately safeguard public health.

This New upgrade MIC-L45 filling CAPPING machine is suitable for:

Medical, Daily chemistry, cosmetics. Small glass bottles and plastic bottles such as electronic liquids, vaccine, essential oils, syrups, etc.

Main Features

1. Microcomputer setting, high filling accuracy

2. The main engine is equipped with stepless frequency speed control.

3. Automatic production capacity quantitative control.

4. With all kinds of fault alerting, for low pressure, no filling, no inner cap etc.

5. The machine can stop automatically in case of no filling, no inner cap etc.

This machine body made by stainless steel, and the working process is controlled by touch screen, and the filling volume is adjustable.

This machine is suitable for filling capping small bottle of various specifications.

According to customer filling material viscosity to choose piston filling system or peristaltic pump filling system.

According to customer’s requirement, we will offer our technician for oversea to install and adjust machine.

We provide the full-lifetime warranty consult with one-year free accessories, if you need.

We also can arrange the engineer to your factory do field installation guidance.

Filling head

When the bottle through the conveyor belt was sent to the location of the chuck, automatic identification of sensors, control by internal program to send signals for filling station, when the bottle comes under the filling head, cylinder head began to move down the drive filling, filling process without dripping, do not waste material, also can ensure the bottle clean and tidy, convenient after labeling.

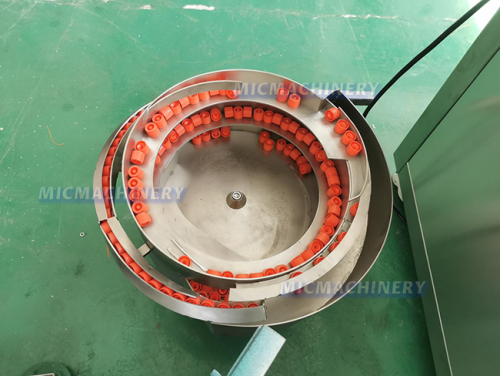

Screw capping head

His job is to tighten the lid on a bottle that has been filled , which is the last step on the main bench.

When the bottle reaches under the Screw capping head, the machine automatically recognizes and the Screw capping head moves downward to tighten the cap quickly.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback: