|

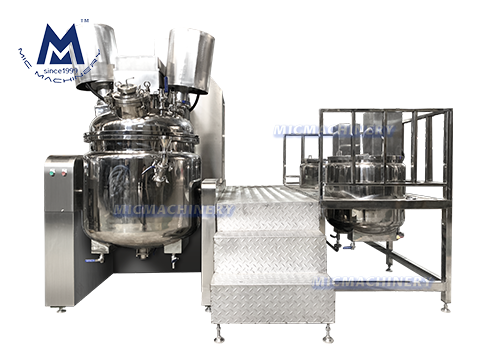

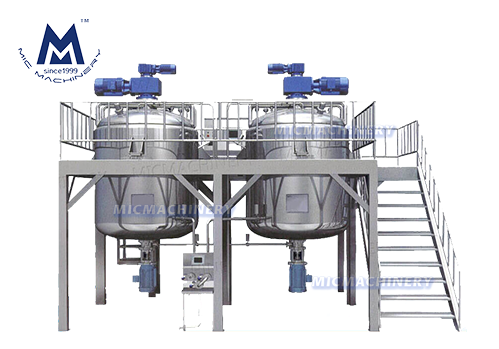

Vacuum Homogenizer Mixer |

|||||||||||

|

Model |

10L |

30L |

50L |

100L |

150L |

200L |

300L |

500L |

600L |

1000L |

|

|

Working Capaicty |

10 |

30 |

50 |

100 |

150 |

200 |

300 |

500 |

600 |

1000 |

|

|

Emulsify |

KW |

0.75 |

1.1 |

2.2 |

3 |

4 |

4 |

4 |

7.5 |

11 |

11 |

|

|

Min/r |

0-2800 |

0-2900 |

0-2800 |

0-2800 |

0-2800 |

0-2800 |

0-2900 |

0-3500 |

0-3500 |

0-3500 |

|

Agitator |

KW |

0.55 |

1.1 |

1.1 |

1.1 |

1.5 |

1.5 |

2.2 |

2.2 |

4 |

4 |

|

|

Min/r |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

|

Machine Dimension |

Length |

1100 |

1650 |

1500 |

1700 |

1100 |

2600 |

1100 |

3000 |

3000 |

4800 |

|

|

Width |

600 |

600 |

600 |

650 |

600 |

1900 |

600 |

2500 |

1300 |

3000 |

|

|

Height |

1500 |

1700-2300 |

1900-2500 |

1700-2700 |

1700-2700 |

2500-3500 |

2500-3500 |

3200-4500 |

3200-4500 |

2500-3850 |

Revolutionize Emulsification with a Vacuum Emulsifier Mixer

Introduction:

In industries that demand precise and efficient emulsification processes, the vacuum emulsifier mixer stands out as a versatile and powerful tool. This technical article explores the features, benefits, and applications of vacuum emulsifier mixers, highlighting their role in achieving superior emulsion quality and stability.

Vacuum Emulsifier Mixer:

A vacuum emulsifier mixer is an advanced piece of equipment specifically designed to create stable and high-quality emulsions. This machine combines the benefits of a mixer and a homogenizer while operating under vacuum conditions. The vacuum emulsifier mixer ensures efficient dispersion, uniform particle distribution, and reduced air entrapment, leading to emulsions with improved stability and texture.

Vacuum Emulsifier Homogenizer:

The vacuum emulsifier homogenizer is a versatile tool widely used in industries such as cosmetics, pharmaceuticals, food, and chemicals. This equipment combines the functions of emulsification and homogenization while operating under vacuum conditions. The vacuum emulsifier homogenizer enables precise control over parameters such as speed, temperature, and pressure, resulting in stable emulsions with fine droplet sizes and enhanced product quality.

Vacuum Emulsifier Machine:

A vacuum emulsifier machine is a highly efficient and reliable piece of equipment used for emulsion production. With its vacuum capabilities, this machine eliminates air bubbles and reduces the oxidation of sensitive ingredients. The vacuum emulsifier machine delivers consistent emulsion quality, improved stability, and extended shelf life, making it an essential tool in industries where product integrity and preservation are crucial.

Vacuum Emulsifier:

The vacuum emulsifier is a specialized device designed to create emulsions by dispersing two immiscible liquids under vacuum conditions. This equipment operates by reducing pressure, which minimizes air entrapment and enhances the stability and quality of the emulsion. Vacuum emulsifiers find extensive use in industries such as cosmetics, pharmaceuticals, and food, where fine emulsions and product consistency are vital.

Vacuum Homogenizer Emulsifier:

The vacuum homogenizer emulsifier is a versatile machine that combines the benefits of homogenization and emulsification while operating under vacuum conditions. This equipment ensures the reduction of particle sizes, uniform distribution of ingredients, and elimination of air bubbles, resulting in stable and homogeneous emulsions. The vacuum homogenizer emulsifier is commonly used in industries requiring precise control over the emulsification process, such as cosmetics, pharmaceuticals, and food manufacturing.

Vacuum Homogenizing Emulsifier:

The vacuum homogenizing emulsifier is an advanced piece of equipment that combines homogenization and emulsification capabilities under vacuum conditions. This machine effectively disperses and mixes immiscible liquids, resulting in stable emulsions with fine droplet sizes. With its precise control and superior emulsification performance, the vacuum homogenizing emulsifier is widely employed in industries seeking to achieve consistent and high-quality emulsion-based products.

Vacuum Mixer Emulsifier:

The vacuum mixer emulsifier is a versatile machine designed to mix and emulsify materials under vacuum conditions. This equipment provides efficient blending and dispersion, resulting in stable emulsions with enhanced product quality and stability. The vacuum mixer emulsifier is widely used in industries such as cosmetics, pharmaceuticals, and food, where precise emulsion control and high-performance mixing are paramount.

Conclusion:

Vacuum emulsifier mixers have revolutionized the emulsification process in various industries. With their ability to create stable and high-quality emulsions under vacuum conditions, these machines deliver superior product consistency, texture, and stability. By incorporating vacuum emulsifier mixers into their manufacturing processes, industries can achieve precise control, reduced air entrapment, and extended shelf life of emulsion-based products, leading to enhanced customer satisfaction and a competitive edge in the market.