- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

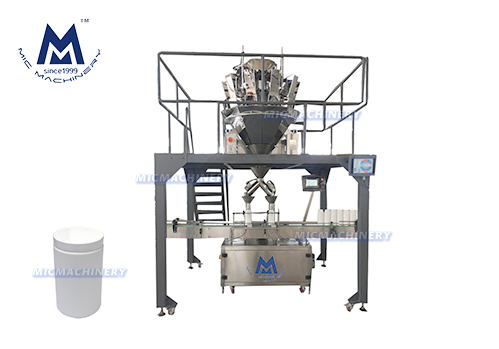

In the realm of granule packaging, precision and efficiency are paramount for ensuring product quality and optimizing manufacturing processes. The Double-Head Linear Granule Filling Machine stands out as an invaluable solution, offering meticulous and efficient filling for granular products. Let's explore how this equipment optimizes performance, focusing on its role as a granule filling machine, granule packing machine, and granule packaging machine.

Maximizing Performance with Double-Head Linear Granule Filling Machine

Accurate Granule Filling: The Double-Head Linear Granule Filling Machine ensures precise and consistent filling of containers with granular products. Equipped with two filling heads and advanced dosing mechanisms, this equipment delivers uniform filling levels, minimizing product variations and ensuring packaging integrity.

Enhanced Efficiency: Serving as a granule packing machine, this equipment streamlines the packaging process by doubling the filling capacity. With its dual-head design, it significantly reduces filling time, increasing production throughput and optimizing operational efficiency.

Reliable and Versatile Operation: As a granule packaging machine, the Double-Head Linear Granule Filling Machine excels in reliability and versatility. Its adaptable design accommodates various container sizes and shapes, catering to diverse packaging requirements without compromising performance.

Serving as a Granule Filling Machine, Granule Packing Machine, and Granule Packaging Machine

Granule Filling Machine: The Double-Head Linear Granule Filling Machine serves as a dedicated solution for filling containers with granular products. Its precise engineering and dual-head design ensure accurate dosing and efficient filling, making it an essential asset in granule filling operations.

Granule Packing Machine: Specifically designed for granule packing, this equipment automates the filling process, doubling the packaging efficiency. Its intuitive controls and high-speed operation ensure seamless integration into production lines, optimizing packaging operations for granular products.

Granule Packaging Machine: With its comprehensive packaging capabilities, the Double-Head Linear Granule Filling Machine offers versatility and reliability in granule packaging applications. Whether packaging snacks, grains, or powders, this equipment delivers consistent and high-quality packaging, meeting diverse market demands with ease.

Conclusion

The Double-Head Linear Granule Filling Machine represents a fusion of precision, efficiency, and versatility in granule packaging. Whether serving as a granule filling machine, granule packing machine, or granule packaging machine, it plays a pivotal role in optimizing manufacturing processes and ensuring product quality. By investing in this advanced equipment, manufacturers can streamline operations, reduce costs, and meet consumer demands with confidence.

This machine is suitable for bottle filling of granules and powders. Measuring cup type. Easy to operate, PLC control, all operations are done on the touch screen. This machine complies with GMP requirements.With PLC programmable touch screen control, it can be used for double hoppers to cut materials at the same time. Used in combination with a combination scale, it has high speed and high precision.

1.The appearance and material contact part of the equipment and material contact part of the production line is used for 304 stainless steel, and all the machine structures are selected and designed according to the food hygiene standard.

2. The structure of frequent disassembly and washing adopts the connection of detachable parts to ensure that it is convenient to handle the shift or change the product.

3.With PLC control, it has stable work, anti-interference and high weighing precision.

4.High speed and high precision.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.