- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the heart of apiaries, where honey's golden essence meets modern ingenuity, the Honey Stick Filling Machine stands as a beacon of efficiency and precision. This cutting-edge device seamlessly merges tradition with technology, revolutionizing the way honey sticks are filled and sealed. By delving into its unique product characteristics, versatile applications, and the fundamental mechanical principles guiding its operation, we uncover its pivotal role in the honey industry. From buzzing apiaries to the shelves of gourmet stores, this machine ensures that every honey stick brims with the sweetness of nature’s nectar.

Product Characteristics:

The Honey Stick Filling Machine boasts exceptional product characteristics designed for reliability and consistency. Crafted from high-quality materials, it guarantees durability and longevity, even under high-volume production. Its customizable filling options cater to various honey viscosities, ensuring the perfect consistency for every stick. Equipped with precision dosing systems, the machine ensures accurate filling, minimizing wastage and maximizing efficiency. Its user-friendly interface enables seamless operation, allowing producers to adjust filling quantities with ease. Anti-drip nozzles and advanced sealing mechanisms maintain the integrity of honey, preventing leaks and preserving freshness.

Product Applications:

The applications of the Honey Stick Filling Machine are as diverse as the honey varieties it accommodates. Small-scale beekeepers and large honey producers alike rely on this machine to create neatly filled honey sticks, perfect for farmers' markets, festivals, and souvenir shops. Health food stores and gourmet retailers benefit from the uniformity and visual appeal of these filled sticks, enhancing their offerings to health-conscious consumers. The machine is also invaluable for promotional events, allowing businesses to create branded honey sticks, a popular choice for corporate gifts and marketing campaigns. Moreover, it caters to honey enthusiasts who prefer the convenience of individually portioned sticks for their daily consumption.

Mechanical Principle:

At its core, the Honey Stick Filling Machine operates on fundamental mechanical principles designed for precision and speed. Utilizing advanced pumps and filling heads, the machine accurately measures and dispenses the specified quantity of honey into individual sticks. Automated conveyor systems facilitate the smooth movement of sticks throughout the filling process. Anti-foaming and anti-clogging mechanisms ensure uninterrupted operation, maintaining consistency in the fill levels. Sealing mechanisms, often utilizing heat or ultrasonic technology, secure the sticks, preserving the honey’s freshness. Integrated sensors and controllers oversee the entire process, ensuring uniformity and minimizing errors, making the filling operation seamless and reliable.

In conclusion, the Honey Stick Filling Machine represents the pinnacle of innovation in the honey industry. Its exceptional product characteristics, diverse applications, and fundamental mechanical principles make it an indispensable asset for businesses aiming for precision, efficiency, and quality in filling honey sticks. Embracing the latest technological advancements, this machine ensures that each honey stick encapsulates the natural sweetness of honey, delighting consumers and enhancing the market presence of honey producers and retailers alike.

This machine is suitable for automatic packaging of liquid of foods, medicine and chemicals,such as pesticide,shampoo,body foam bath lotion, facial cream, ingredient oil, fruit sauce,tomato ketchup and honey shower gel, skin lotion, toothpaste, cosmetic cream, fruit jam, edible oil, soy etc .

Machine features:

1. This machine can finish : forming bag--measuring--material filling—sealing—counting—date code printing, all the work automatically;

2. Photoelectric and tracing system or computer system can be provided without your specific requirements.

3. The PLC controller has the advantages such as setting the length of the bag; the out put alarm and the speed and quantity with buttons;

4. This machine can be installed to code printer for 1-3 lines characters such as production and expiry date according to your special request.

5.Eye Mark System ,machine can cut complete logo.

6.Machine Stop Automaticlly if it is out of film.

7.Fine Packaging performance.low noies .clear sealing texture and strong sealing performacnce.

Applicable packing film:

Paper/PE, PT/PE, PET/AL/PE, BOPP/PE, Tea filter paper and other compound materials can be heat sealed.

Control Panel

The control panel on the filling machine is the core of the machine,it consists of touch screen,power switch, emergency button You just need to press the corresponding button and the machine will follow the correct program.

The PLC controller has the advantages such as setting the length of the bag; the out put alarm and the speed and quantity with buttons;

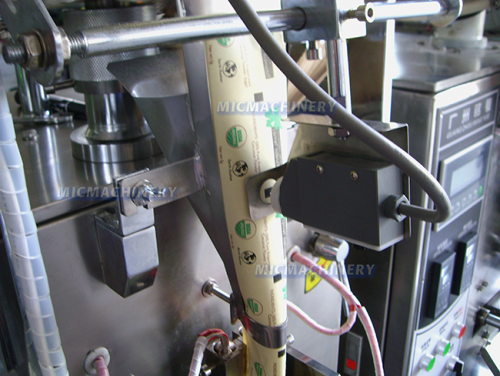

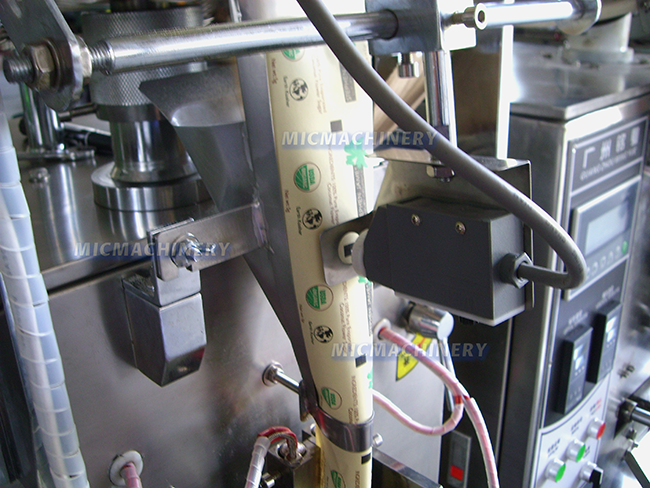

Sensor

The sensor senses the location of the film, telling the machine where to cut the bag.Photoelectric and tracing system or computer system can be provided without your specific requirements.

Bag Former

This machine can finish forming bag--measuring--material filling—sealing—counting—date code printing, all the work automatically;Fine Packaging performance.low noies .clear sealing texture and strong sealing performacnce.

In addition to,If you're looking for honey filling machine,honey packaging machine,honey packing machine,honey stick filling machine,honey straw filling machine,honey bottling machine,honey stick machine,swienty filling machines,honey sachet packing machine,manual honey filling machine,it is a pleasure for you to visit our website anytime

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.