- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the fast-paced world of liquid soap manufacturing, precision, efficiency, and reliability are essential for meeting consumer expectations and staying ahead of the competition. Enter the 8-heads linear filling machine, a cutting-edge solution designed to optimize performance in liquid soap filling and packaging processes. Let's explore how this advanced equipment enhances efficiency and why it's an indispensable asset for liquid soap manufacturers, serving as both a liquid soap bottle filling machine and a liquid soap packaging machine.

Maximizing Performance with the 8-Heads Linear Filling Machine

Efficiency Enhancement: With eight heads, this filling machine operates with exceptional efficiency, allowing for simultaneous filling of multiple liquid soap bottles. This multi-head configuration significantly increases production throughput, minimizing downtime, and maximizing resource utilization.

Precision Engineering: The linear filling mechanism of the 8-heads machine ensures accurate dosing of liquid soap into each bottle. Equipped with advanced control systems and precise dosing mechanisms, it maintains consistent fill levels, improving product quality, and reducing wastage.

Versatility: Designed to accommodate various bottle sizes and types, the 8-heads linear filling machine offers unmatched flexibility in liquid soap packaging. Whether it's PET bottles, HDPE containers, or glass jars, this machine caters to diverse packaging requirements, empowering manufacturers with adaptability.

Serving as a Liquid Soap Filling and Packaging Machine

Liquid Soap Filling Machine: As a liquid soap filling machine, the 8-heads linear model excels in accurately and efficiently dispensing liquid soap into bottles. Its advanced technology ensures precise dosing, reducing product waste, and ensuring consistent fill levels.

Liquid Soap Packaging Machine: Beyond filling, this machine serves as a comprehensive liquid soap packaging solution. Its versatility allows for seamless integration into packaging lines, facilitating labeling, capping, and sealing processes to create a finished product ready for distribution.

Soap Bottle Filling Machine: Designed specifically for soap bottle filling applications, this machine streamlines the process of filling liquid soap into various bottle types. Its linear configuration and high-speed operation ensure rapid and efficient filling, maximizing production output.

Conclusion

In the competitive landscape of liquid soap manufacturing, the 8-heads linear filling machine stands as a symbol of efficiency, precision, and versatility. Its dual role as both a liquid soap bottle filling machine and a liquid soap packaging machine underscores its importance in streamlining production processes and meeting market demands effectively. By investing in this advanced equipment, liquid soap manufacturers can optimize their operations, reduce costs, and maintain a competitive edge in the industry.

This filling machine is suitable for:

pesticides, chemicals, bottled agent type liquid dispensing, bottle filling, Applicable to a variety of different types of containers.

Such as pesticides, pesticides, disinfectants, medical alcohol, detergents, preservatives, etc.

This machine function is:

1. This machine combines optical, mechanical, electrical, gas in one machine.

2. Adopt through control filling time to reach different volume filling.

3. Filling time can be precisely controlled to a hundredth of a second.

4. The filling process is completed under the PLC program control on the touch screen.

5. Having a stable and reliable operation, high efficiency, adaptability, the filling volume of measurement specification can be changed within a few minutes.

6. Filling valve use imported brands, advanced technology, sophisticated, non-drip filling phenomenon.

7. All parts frame, conveyor ,valve ,filling nozzle use anti-corrosion material.

8. Can customize vacuum or diving filling avoid have foma when filling.

This machine is our MIC automatic inline straight line normal pressure filling machine, can Prevent corrosion.

It can be used with capping machine, labeling machine supporting the formation of the production line.

This machine is guaranteed for one year and you can extent your guarantee easily by discuss with our sales.

Which you might be interested, under guaranteed, machine parts got broken by daily use, we will replace it once we are informed by free DHL.

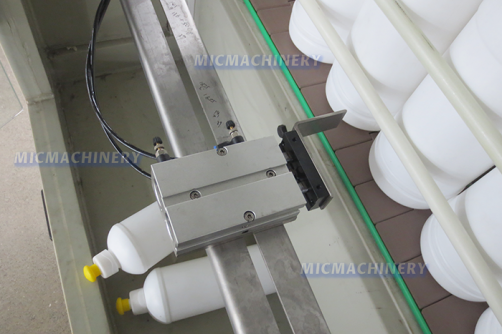

Bottle block air cylinder

When the bottle can reach a certain number, there is a special infrared sensor on the bottle track to receive the induction, and then automatically stuck behind the bottle, in front of the bottle after the bottle filling, and then let the behind the bottle to fill the vacancy, so as to achieve no bottle no filling

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of bottle,The width between the two pipes can be adjusted according to your container,ensure smooth bottle safely from the conveyor belt moved .

on the side of the conveyor is equipped with sensors that can automatically identify when the bottle to go out or, in order to send signals to filling station of screw cap

Two-way valve and filling head

This machine is designed for highly corrosive liquid filling tailored. All parts in contact with the liquid have adopted anti-corrosion materials.

The machine uses pressure-type fixed flow parameters,control filling material time to achieve different measurement filling.

We can customize the quantity of filling head for you according to your needs. In addition, the size of filling head can be adjusted according to the diameter of the barrel

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

pesticides,chemical,cosmetic and other corrosive,High Viscosity Materials, Liquid soap , oil product ,Lotion And So On |

|||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

|||||

|

Speed (basis on 50-500ml) |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

|||||

|

Power |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback: