- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

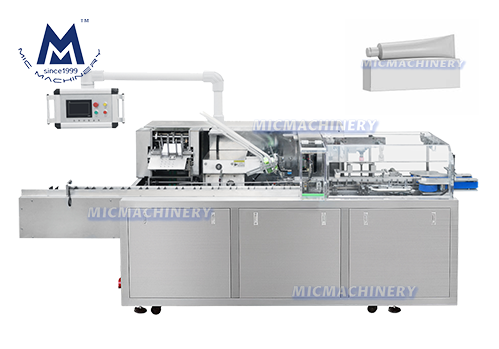

In the realm of efficient and precise packaging solutions, the Small Carton Packing Machine emerges as a compact powerhouse, seamlessly integrating innovation with the demands of diverse industries. This advanced machine stands as a versatile player, offering manufacturers a reliable solution to streamline their packaging processes. As we delve into its distinctive product characteristics, diverse applications, and the intricate mechanical principles guiding its operation, we embark on a journey to uncover the essence of excellence in small carton packaging. From pharmaceuticals to cosmetics and beyond, this machine ensures each carton is packed with accuracy, efficiency, and the promise of optimal production workflow.

Product Characteristics:

The Small Carton Packing Machine boasts an array of exceptional characteristics meticulously engineered for compact precision. Crafted from durable materials, often stainless steel, these machines ensure longevity while maintaining the highest standards of quality. Featuring automated carton feeding, filling, and sealing mechanisms, they strike a delicate balance between space efficiency and the intricacies of varied packaging needs. Designed with user-friendly interfaces and adjustable controls, these machines accommodate different carton sizes and specifications, ensuring each product receives a consistent and accurate packaging. Equipped with anti-jamming features and secure sealing capabilities, these machines preserve the integrity of packaged items, delivering products that resonate with both quality and the promise of efficient packaging.

Product Applications:

The applications of the Small Carton Packing Machine span a wide spectrum of industries, offering a comprehensive solution for efficient and precise carton packaging. Whether packaging pharmaceuticals, cosmetics, or small consumer goods, these machines ensure uniformity in dosage and presentation. The adaptability of the Small Carton Packing Machine caters to the dynamic needs of industries, where each product requires a tailored approach to packaging, labeling, and preserving its unique characteristics.

Mechanical Principle:

At its core, the Small Carton Packing Machine operates on advanced mechanical principles designed for compact efficiency. Utilizing carton feeding systems, filling mechanisms, and sealing components, the machine accurately and swiftly packages products into individual cartons. Sealing mechanisms, employing high-speed technology, secure the cartons, ensuring a tight seal and preserving the freshness and integrity of the packaged items. Integrated sensors and programmable logic controllers (PLCs) oversee the entire process, ensuring uniformity, minimizing errors, and enhancing the overall efficiency of small carton packaging operations.

In conclusion, the Small Carton Packing Machine stands as a symbol of precision and efficiency in the packaging industry. Its exceptional product characteristics, diverse applications, and advanced mechanical principles make it an indispensable asset for manufacturers globally. Embracing cutting-edge technology, this machine not only ensures the accuracy of small carton packaging but also upholds the highest standards of presentation, consistency, and quality. As a fundamental component in various production workflows, it continues to shape the way products are packaged, ensuring each carton embodies the essence of precision and the promise of efficient delivery to end-users.

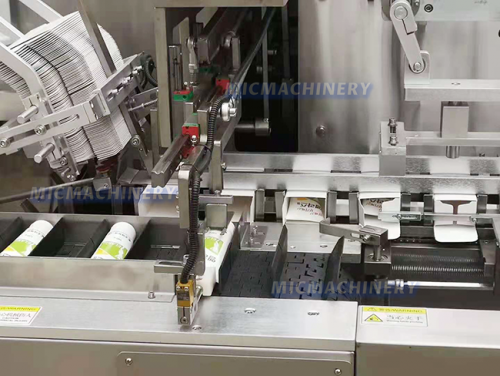

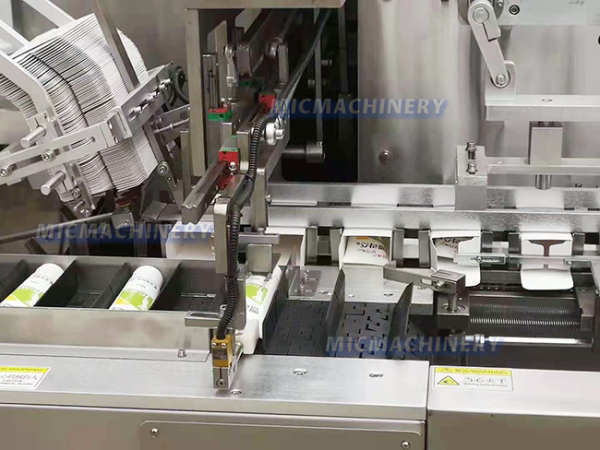

box opening

When the sensor senses that there is a tube coming in, it will send a signal to the automatic opening of the box through the internal system. The servo motor drives the efficient opening of the box. This process will automatically display the packaging speed and packaging situation, to ensure that one tube one box, no waste of materials, the packaging effect is very good.

Push tube system

The conveyor belt sends the products to the packing station one by one. When the products arrive, the box will be opened and the machine will automatically push the products into the box accurately.

When there is no product or product supply is not in place, the machine will sit idle without pushing the product. It will run automatically when the product is returned to supply.

Feature:

Carton automatically open and transfer, automatically load the material into carton; And complete both ends of the paper tongue and other complex packaging process. The appearance of the machine is all made of high quality stainless steel shell, strictly in accordance with the pharmaceutical industry "GMP" standard innovative design. The transmission part designed overload protection function, and set up an emergency stop device, the control system adopts man-machine interface video screen, to ensure the safety of the operator.

Main performance and structural characteristics:

1. Adopt automatic feeding, box opening, box entering, box sealing and output. Packaging form, compact and reasonable structure, simple operation and adjustment;

2. Servo/stepper motor and touch screen, PLC programmable control system, man-machine interface display operation is more clear and simple, high degree of automation, more humanized;

3. Photoelectric eye automatic detection and tracking system, no product no box, save the packaging material to the greatest extent;

4. Large packing range, convenient adjustment, quick conversion between various specifications and sizes;

5. No need to change the mold to replace the specifications, just adjust it to achieve;

6. When there is no product or product supply is not in place, the machine idles without pushing the product. When the product is restored to supply, it will automatically run.

7. Automatic display of packing speed and counting:

8. According to customer requirements, the use of upturn type safety cover, easy to operate, beautiful appearance.

9. Linkage production can be realized with other production lines and other equipment;

10. Automatic feeder and box feeding system can be designed according to packaging requirements;

11. Hot melt glue machine can be selected according to customer requirements.

Operation brief:

Pre-operation preparation

Check whether the power/air source is connected properly before operation

The cartons are put into the carton bin in sequence, and the equipment can be run after the protective cover is closed

The operating process principle is introduced

1. When the packing machine connects with the sealing filling machine, the products will be transferred to the material conveyor belt of the packing machine automatically and orderly

2. There are light eyes on the material conveyor belt, which will control the carton warehouse to open the box after detecting the product

3. The product and carton will be synchronized to the push port

4. Push rod work, push the product into the corresponding carton, sealing mechanism work, carton sealing

In addition to,If you're looking for toothpaste packaging machine ,Toothpaste Filling Machine,toothpaste tube filling machine,toothpaste tube filling and sealing machine,toothpaste filling and sealing machine price,Please feel free to visit our website

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback: