- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

This machine is suitable for filling a liquid and sauce cream products, especially for high viscosity materials, the effect is obvious.

1. Adopt PLC programmable control system with touch screen interface.

2. Automatic bottle feeding, automatic filling, automatic bottle.

3. Adopt servo motor drive, double screw-rod drive, Control the movement of the piston rod to ensure the stability of the filling.

4. Adopt double-ball screw rod filling the filling nozzle dive

5. It can be used with capping machine, labeling machine supporting the formation of the production line

6. It combines optical, mechanical, electrical, gas in one. It is easy to operate a filling machine.

7. Having a stable and reliable operation, high production efficiency, strong adaptability.

Elevating Nutty Delights: Introducing the Peanut Butter Filling Machine

Innovating Nut Butter Packaging: Introducing the Peanut Butter Filling Machine

Step into the future of precision packaging with our advanced Peanut Butter Filling Machine, a cornerstone in the evolution of nut butter packaging technology. Seamlessly integrating distinctive product characteristics, versatile applications, and cutting-edge mechanical principles, this machine redefines excellence in filling and packaging processes, extending its capability to fill Mayonnaise, Sauce, and Yogurt into bottles.

Product Characteristics: At the heart of this technological marvel are precision and efficiency. The Peanut Butter Filling Machine is meticulously engineered, boasting features that ensure a seamless and accurate filling process. Its adaptability shines through, making it suitable for filling not just peanut butter but also Mayonnaise, Sauce, and Yogurt into bottles. The machine's robust construction, user-friendly interface, and flexible configurations characterize it as a reliable asset for businesses seeking top-tier packaging solutions.

Product Application: Versatility is a defining feature of this machine, extending its capabilities beyond traditional peanut butter packaging. Specifically designed to fill Mayonnaise, Sauce, and Yogurt into bottles, the Peanut Butter Filling Machine becomes an indispensable solution for industries spanning from condiments to dairy. Whether you are a producer of creamy nut butter or savory sauces, this machine ensures a uniform and efficient bottle-filling process, enhancing the visual appeal and convenience of your products.

Mechanical Principle: The operational brilliance of this machine lies in its advanced mechanical principles, finely tuned for optimal efficiency. The Peanut Butter Filling Machine optimizes the filling process with precision and speed. The filling mechanism ensures a consistent and accurate distribution of Mayonnaise, Sauce, and Yogurt into each bottle, minimizing wastage and maximizing overall output. Embracing innovative features, this machine becomes a game-changer for businesses aiming to elevate their production processes.

In conclusion, the Peanut Butter Filling Machine is more than a packaging tool; it's a symbol of innovation in nut butter packaging. With its distinctive product characteristics, versatile applications, and advanced mechanical principles, this machine is poised to redefine the standards of precision and efficiency in the industry. Whether you are filling peanut butter or crafting other liquid delights, this forward-thinking solution is ready to elevate your bottle-filling processes and contribute to the success of your business.

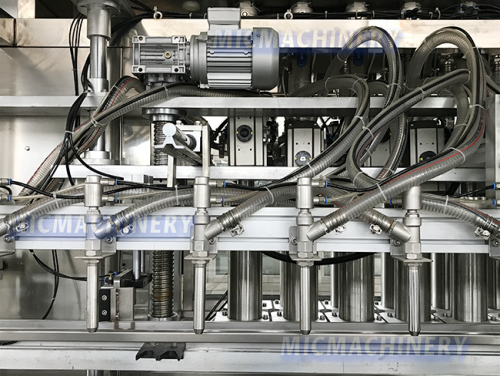

filling head

The Peanut Butter is put into the material cylinder, the piston to pump the Peanut Butter into the measuring cylinder. Then the piston moves up to send the Peanut Butter to the filling pipe. At the same time, when the bottle enters the filling machine through the conveyor belt, the filling head moves down to start filling. After filling, the conveyor belt will automatically send the bottle to the capping station.

(Filling process without drip leakage, the number of filling head can be customized according to your needs and diameter of filling head basis on the diameter of your barrel’s mouth)

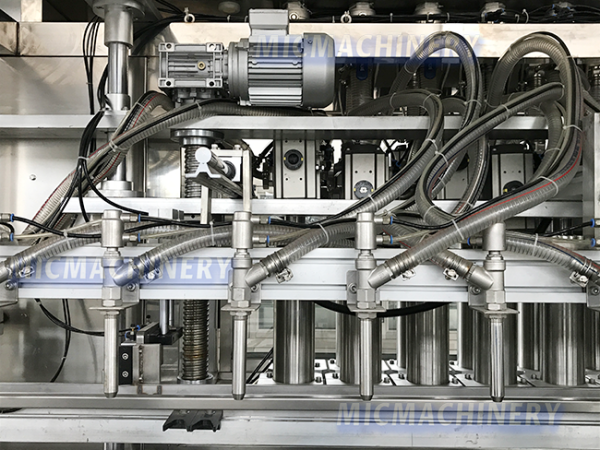

the three-way valve

the three-way valve is controlled by PLC system, The three-way valve rotates internally to adjust the connection between the material box and the measuring cylinder cylinder or the measuring cylinder cylinder and the filling pipe. Accordingly it controls the movement of materials from the material tank to the dosing cylinder and then to the filling pipe.

Main working process: downward movement of the piston to fill the material from the material cylinder to the measuring cylinder, and then controls the upward movement of the piston to send the material to the filling pipe and start filling

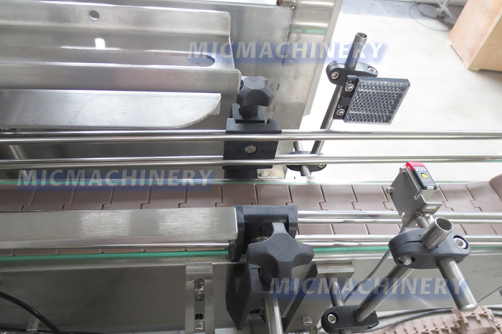

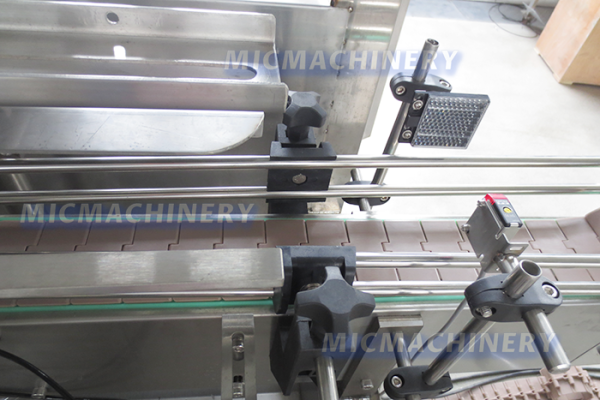

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time .

This conveyor belt can be different size of bottle,The width between the two pipes can be adjusted according to your container,ensure smooth bottle safely from the conveyor belt moved.

on the side of the conveyor is equipped with sensors that can automatically identify when the bottle to go out or, in order to send signals to filling station of screw cap

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed |

5-25 B/M |

192-220 B/h (basis on 25L) |

1300-1500 B/h (basis on100ml bottle) |

≤1800 B/h ( basis on 1000ml bottle) |

3000B/h (basis on 350ml) |

3200 B /h |

≤4000 B/h (basis on1L bottle) |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.0Kw |

2.8kw |

3kw |

2.8kw |

2Kw |

3.0Kw |

|

Size |

1000*480*700 mm |

2500*1600*2500 mm |

1840*1400*2500 mm |

2000*1400*2500 mm |

1600*1400*2300 mm

|

2440*1240*2350 mm |

2800 *1400*2500 mm |

|

Weight |

35 Kg |

700 kg |

600kg |

1000kg |

3000Kg |

700 kg |

1000 kg |

In addition to,we have jam filling machine,jam packing machine,jam jar filling machine,jam packaging machine,manual jam filling machine,sauce filling machine,tomato sauce filling machine,hot sauce bottling machine,sauce bottling machine.

If you are more than interested in the machine ,you can contact us at market@micmachinery.com

in short, we will try our best to provide you with satisfactory service,the following is our customer feedback.