- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

This Tincture Bottle Filler is a fully automatic model specially designed for perfume bottles.

The process is: bottle feeding-filling-press the spray-seal spray(crimping) -put the outer cover-press the outer cover Of course you can also choose to put the spray and outer cover manually.

Advantages:

1.Small and saving space

2.Efficient and precise

3.Easy to operate and flexible

4.Stainless steel body, neat and beautiful

This Tincture Bottle Filler main features

1) Adopting advanced world famous brand components in pneumatic parts, electric parts and operation parts.

2) Running in a high automatization and intellectualization, no pollution

3) Self bottle loaded

4) The body is made of stainless steel, which is clean and durable

5) Precision filling, no tube will not be filled

The machine accepts customization, please contact us for more information.

mould and negative vacuum filling

The mould used to fix the filling container Then the circular reels carry the bottles to the filling and capping stations

Cap loading automatically

cap feeding cage with vibrating piate is connected to a pipe that carries the cap,They automatically arranges the cap and deliver the cap Put the cap on the filled bottle.

In this way, the bottle is covered in a consistent process, reducing the manual contact with the bottle process, and ensuring better hygiene,At the same time, labor costs are reduced

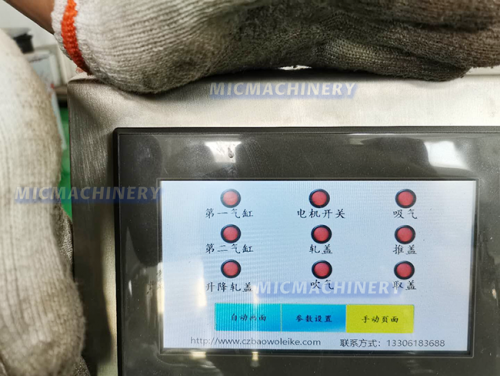

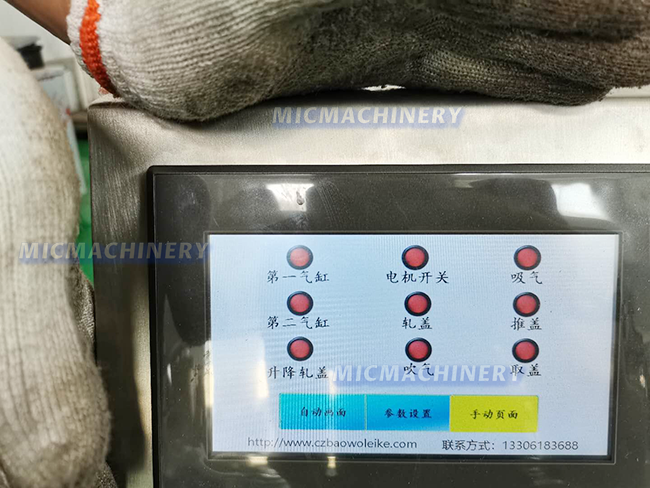

Control panel by Siemens touch screen

The control panel on the filling machine is the core of the machine,it consists of touch screen,power switch, emergency button you just need to press the corresponding button and the machine will follow the correct program.

An Alarm Screen will also be included on automatic filling equipment to notify packagers when there is an issue with the filling equipment or the packaging line in general. In addition to notification, the screen can assist with identifying the issue if the same is not immediately obvious.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Filling Volume |

10-100ml |

|

Filling nozzle |

2 or 3 nozzles |

| Output |

20-30 bottles each minute |

|

Filling Error |

≤±1% |

| Power Supply |

220v 50Hz |

| Capping Rate |

≥99% |

|

Air supply |

1.3 m3/h 0.4-0.8Mpa |

|

Power |

2.0 kw |

|

Weight |

2.0 kw |

|

Dimension |

1800*1000*1500mm |

|

Setup component

|

Brand |

|

Rack material |

SUS 304 |

|

Tank, nozzle, liquid touches place |

SUS 304 / medical silica gel |

|

Air componnet |

Airtac |

|

Touch screen |

Siemens Germany 21 cm color |

|

Sensor |

LEUZE Germany or SICK |

|

Relay & air switch |

Schneider French |

|

Transducer Motor |

Schneider French |

|

Conveyor material |

82mm width SUS 304 Chain belt |

|

Conveyor motor |

AC motor China brand |

|

Filling form |

Piston filling (80-90) and vacuum filling (for accuracy) |

|

Turnable tray motor, capping motor, |

China brand |

|

Explore parts |

SUS 304, Positive oxidation treatment aluminum alloy Electroplate No.#45 steel and plastic. |

|

Vacuum pump |

China brand |

- MIC Automatic Tincture Filling Machine ( Syrup, Essential Oil, Tincture, 20-30 Bottles/min )

- MIC Semi Automatic Tincture Bottle Filling Machine ( Perfume, Tincture, 20-30 Bottles/min )

- MIC Tincture Bottle Filler ( Syrup, Tincture, Essential Oil, 10-40 Bottles/min )

- MIC Automatic Tincture Bottle Filler ( Vial, Tincture, Syrup, 20-30 Bottles/min )

- MIC Tincture Filling Machine ( Syrup, Vial, Tincture, 20-30 Bottles/min )

- MIC-L40 Tincture Bottle Filling Machine ( Syrup, Tincture, Vial, 20-30 Bottles/min )