- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Enhancing Efficiency and Precision: Deodorant Roll-On Bottle Filling and Capping Machine

In the personal care industry, precision and efficiency are paramount to meet consumer demands and maintain product quality. The Deodorant Roll-On bottle filling capping machine stands out as an indispensable asset in this process, offering exceptional performance tailored to the specific needs of deodorant production. Let's delve into its significance, focusing on its role as a deodorant filling machine, deodorant bottle filling machine, and deodorant stick filling machine.

Optimizing Filling Precision

Accurate Deodorant Dispensing: The Deodorant Roll-On bottle filling capping machine is engineered to dispense deodorant into roll-on bottles with unmatched precision. Leveraging advanced dosing mechanisms and precise filling technologies, this machine ensures consistent fills, maintaining product integrity and quality. Whether filling glass or plastic bottles, it guarantees uniform deodorant distribution, minimizing product wastage and maximizing yield.

Efficient Filling and Capping Operations: Tailored for high-volume deodorant production, this machine offers swift and efficient filling and capping processes. Its automated functionalities enable uninterrupted operation, significantly reducing production time and labor costs. With adjustable filling speeds and customizable settings, it accommodates varying production requirements, ensuring optimal efficiency across different deodorant formulations and bottle sizes.

Versatility and Adaptability: The Deodorant Roll-On bottle filling capping machine excels in handling a wide range of bottle styles, sizes, and materials commonly used in the industry. Whether filling roll-on bottles, spray bottles, or stick applicators, it seamlessly adapts to diverse packaging formats. Its flexible design allows for quick changeovers between different bottle types, facilitating production versatility and minimizing downtime.

Significance in Deodorant Production

Deodorant Filling Machine: This machine plays a pivotal role in deodorant production, providing precise and efficient filling solutions. With its ability to accurately dispense deodorant into roll-on bottles, it ensures consistent product dosing and fragrance potency, meeting regulatory standards and consumer expectations. By automating the filling process, it enhances production efficiency and minimizes product wastage, contributing to cost savings and profitability.

Deodorant Bottle Filling Machine: Engineered for fully automated production lines, this machine optimizes the filling and capping process for high-speed operations. Equipped with advanced features such as PLC control systems and servo-driven filling heads, it delivers precise and reliable fills with minimal human intervention. The Deodorant Roll-On bottle filling capping machine ensures uniform filling levels and secure sealing, enhancing product presentation and consumer satisfaction.

Deodorant Stick Filling Machine: Ideal for small to medium-scale production, this machine offers a blend of efficiency and flexibility. Operators can manually load and unload bottles while the machine handles the filling and capping process. It serves as a cost-effective solution for manufacturers looking to increase production capacity without fully automating their operations.

Conclusion

The Deodorant Roll-On bottle filling capping machine is an indispensable asset in deodorant production, offering precision, efficiency, and versatility in bottle filling and capping operations. Whether as a deodorant filling machine, deodorant bottle filling machine, or deodorant stick filling machine, its performance optimizes production processes, upholds product integrity, and satisfies consumer demand. By investing in this advanced filling solution, deodorant manufacturers can streamline their production operations, meet market demands, and maintain a competitive edge in the personal care industry.

In the personal care industry, precision and efficiency are paramount to meet consumer demands and maintain product quality. The Deodorant Roll-On bottle filling capping machine stands out as an indispensable asset in this process, offering exceptional performance tailored to the specific needs of deodorant production. Let's delve into its significance, focusing on its role as a deodorant filling machine, deodorant bottle filling machine, and deodorant stick filling machine.

Optimizing Filling Precision

Accurate Deodorant Dispensing: The Deodorant Roll-On bottle filling capping machine is engineered to dispense deodorant into roll-on bottles with unmatched precision. Leveraging advanced dosing mechanisms and precise filling technologies, this machine ensures consistent fills, maintaining product integrity and quality. Whether filling glass or plastic bottles, it guarantees uniform deodorant distribution, minimizing product wastage and maximizing yield.

Efficient Filling and Capping Operations: Tailored for high-volume deodorant production, this machine offers swift and efficient filling and capping processes. Its automated functionalities enable uninterrupted operation, significantly reducing production time and labor costs. With adjustable filling speeds and customizable settings, it accommodates varying production requirements, ensuring optimal efficiency across different deodorant formulations and bottle sizes.

Versatility and Adaptability: The Deodorant Roll-On bottle filling capping machine excels in handling a wide range of bottle styles, sizes, and materials commonly used in the industry. Whether filling roll-on bottles, spray bottles, or stick applicators, it seamlessly adapts to diverse packaging formats. Its flexible design allows for quick changeovers between different bottle types, facilitating production versatility and minimizing downtime.

Significance in Deodorant Production

Deodorant Filling Machine: This machine plays a pivotal role in deodorant production, providing precise and efficient filling solutions. With its ability to accurately dispense deodorant into roll-on bottles, it ensures consistent product dosing and fragrance potency, meeting regulatory standards and consumer expectations. By automating the filling process, it enhances production efficiency and minimizes product wastage, contributing to cost savings and profitability.

Deodorant Bottle Filling Machine: Engineered for fully automated production lines, this machine optimizes the filling and capping process for high-speed operations. Equipped with advanced features such as PLC control systems and servo-driven filling heads, it delivers precise and reliable fills with minimal human intervention. The Deodorant Roll-On bottle filling capping machine ensures uniform filling levels and secure sealing, enhancing product presentation and consumer satisfaction.

Deodorant Stick Filling Machine: Ideal for small to medium-scale production, this machine offers a blend of efficiency and flexibility. Operators can manually load and unload bottles while the machine handles the filling and capping process. It serves as a cost-effective solution for manufacturers looking to increase production capacity without fully automating their operations.

Conclusion

The Deodorant Roll-On bottle filling capping machine is an indispensable asset in deodorant production, offering precision, efficiency, and versatility in bottle filling and capping operations. Whether as a deodorant filling machine, deodorant bottle filling machine, or deodorant stick filling machine, its performance optimizes production processes, upholds product integrity, and satisfies consumer demand. By investing in this advanced filling solution, deodorant manufacturers can streamline their production operations, meet market demands, and maintain a competitive edge in the personal care industry.

Introducing the Deodorant Bottle Filling Machine:

Our liquid filling and capping machine is an advanced solution designed to efficiently fill various liquid products such as cream, deodorant, e-liquid, essential oil, VG, PG, and seed oil into round bottles. With a customizable filling range from 10 to 100 ml, this versatile machine caters to a wide array of packaging needs.

Key Features:

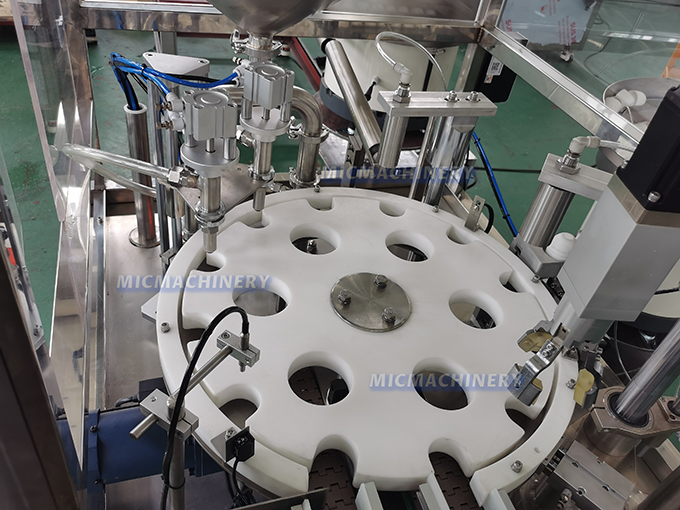

High Precision Cam: Equipped with a high precision cam mechanism, the machine ensures accurate positioning of bottles, corks, and caps, guaranteeing uniformity in packaging.

Accelerating Cam Technology: The accelerating cam facilitates swift movement of capping heads, streamlining the capping process for enhanced efficiency.

Constant Turning Arm: Our machine incorporates a constant turning arm that securely screws caps onto bottles, maintaining seal integrity and preventing leakage.

Peristaltic Pump Filling: Utilizing a peristaltic pump, the machine precisely measures and dispenses the desired volume of liquid, ensuring consistency in product dosage.

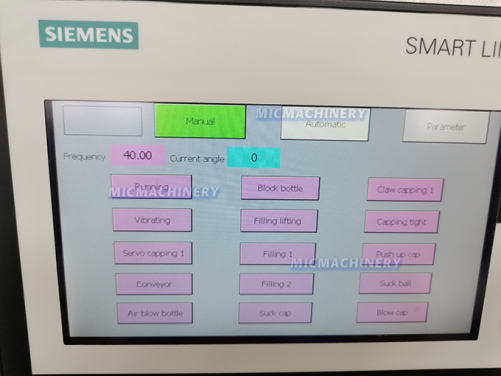

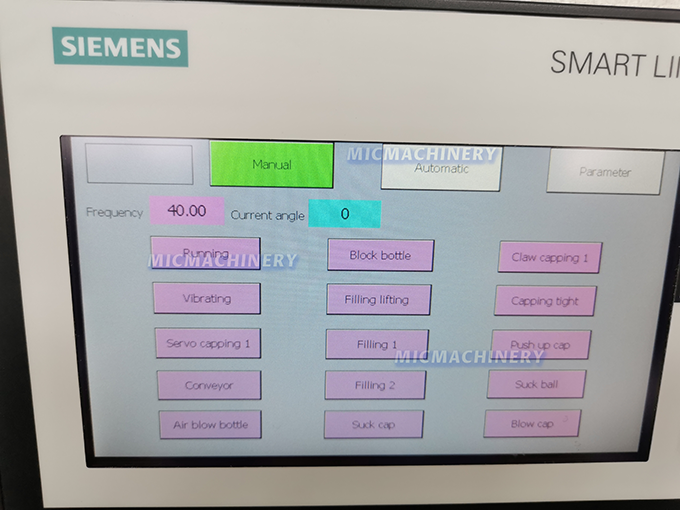

Touch Screen Control: Seamlessly manage all machine functions through an intuitive touch screen interface, allowing for effortless operation and precise control over filling and capping processes.

Automatic Bottle Detection: Incorporating a smart sensor system, the machine automatically detects the presence of bottles, initiating filling and capping processes only when bottles are properly positioned, thus minimizing wastage and optimizing efficiency.

Customizable Filling Range: Tailor the machine to meet your specific requirements with a customizable filling range, accommodating various bottle sizes and product volumes.

Streamlined Operation: Simplify your production process with intuitive touch screen controls and automated functions, reducing labor requirements and maximizing productivity.

Experience unparalleled efficiency and precision in liquid packaging with our Liquid Filling and Capping Machine. Elevate your production capabilities and deliver superior products to your customers with confidence.

Our liquid filling and capping machine is an advanced solution designed to efficiently fill various liquid products such as cream, deodorant, e-liquid, essential oil, VG, PG, and seed oil into round bottles. With a customizable filling range from 10 to 100 ml, this versatile machine caters to a wide array of packaging needs.

Key Features:

High Precision Cam: Equipped with a high precision cam mechanism, the machine ensures accurate positioning of bottles, corks, and caps, guaranteeing uniformity in packaging.

Accelerating Cam Technology: The accelerating cam facilitates swift movement of capping heads, streamlining the capping process for enhanced efficiency.

Constant Turning Arm: Our machine incorporates a constant turning arm that securely screws caps onto bottles, maintaining seal integrity and preventing leakage.

Peristaltic Pump Filling: Utilizing a peristaltic pump, the machine precisely measures and dispenses the desired volume of liquid, ensuring consistency in product dosage.

Touch Screen Control: Seamlessly manage all machine functions through an intuitive touch screen interface, allowing for effortless operation and precise control over filling and capping processes.

Automatic Bottle Detection: Incorporating a smart sensor system, the machine automatically detects the presence of bottles, initiating filling and capping processes only when bottles are properly positioned, thus minimizing wastage and optimizing efficiency.

Advantages:

High Positioning Accuracy: With its advanced technology and precision engineering, our machine delivers unmatched positioning accuracy, resulting in consistently high-quality packaging.Customizable Filling Range: Tailor the machine to meet your specific requirements with a customizable filling range, accommodating various bottle sizes and product volumes.

Streamlined Operation: Simplify your production process with intuitive touch screen controls and automated functions, reducing labor requirements and maximizing productivity.

Experience unparalleled efficiency and precision in liquid packaging with our Liquid Filling and Capping Machine. Elevate your production capabilities and deliver superior products to your customers with confidence.

Siemens PLC touch screen

All operate control by touch screen panel . Such as filling speed and volume , capping speed . Also , the machine is no bottle no filling .

All movements are Programming in the PLC

Turn table chuck

According to customer bottle size to customize . Automatic bottle feeding in the table chuck,finish filling, cap uploading , capping and output.

Servo capping head mechanical claw capping head (servo motor controlled capping claw),the servo claw capping head'sTorque and torque distance are controlled by servo motor, Torque can adjust in touch screen directly), don’t need change capping heads for the different diameter cap (In a fixed diameter range)