- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the realm of liquid packaging, precision and efficiency are essential for maintaining product quality and streamlining manufacturing processes. The Small Pet Bottle Filling Machine serves as a valuable solution, offering meticulous and efficient filling for various liquid products. Let's explore how this equipment optimizes performance, focusing on its role as a pet bottle filling machine, plastic bottle filling machine, and plastic bottle packing machine.

Maximizing Performance with Small Pet Bottle Filling Machine

Accurate Bottle Filling: The Small Pet Bottle Filling Machine ensures precise and consistent filling of pet bottles with liquid products. Equipped with advanced filling mechanisms and precise controls, this equipment delivers uniform filling levels, minimizing product waste and ensuring packaging integrity.

Compact Design: Serving as a plastic bottle filling machine, this equipment features a small footprint, making it ideal for space-constrained manufacturing environments. Despite its size, it maintains high efficiency and accuracy in bottle filling operations, catering to the needs of small-scale producers.

Reliable and Versatile Operation: As a plastic bottle packing machine, the Small Pet Bottle Filling Machine excels in reliability and versatility. Its adaptable design accommodates various bottle sizes and shapes, catering to diverse packaging requirements without compromising performance.

Serving as a Pet Bottle Filling Machine, Plastic Bottle Filling Machine, and Plastic Bottle Packing Machine

Pet Bottle Filling Machine: The Small Pet Bottle Filling Machine serves as a dedicated solution for filling pet bottles with liquid products. Its precise engineering ensures accurate dosing and efficient filling, making it an essential asset in liquid packaging operations.

Plastic Bottle Filling Machine: Specifically designed for plastic bottle filling, this equipment automates the filling process, optimizing efficiency in manufacturing operations. Its compact design and high-speed operation ensure seamless integration into production lines, maximizing throughput and minimizing downtime.

Plastic Bottle Packing Machine: With its comprehensive packaging capabilities, the Small Pet Bottle Filling Machine offers versatility and reliability in plastic bottle packing applications. Whether packaging beverages, household cleaners, or personal care products, this equipment delivers consistent and high-quality packaging, meeting diverse market demands with ease.

Conclusion

The Small Pet Bottle Filling Machine represents a fusion of precision, efficiency, and versatility in liquid packaging. Whether serving as a pet bottle filling machine, plastic bottle filling machine, or plastic bottle packing machine, it plays a crucial role in optimizing manufacturing processes and ensuring product quality. By investing in this advanced equipment, manufacturers can streamline operations, reduce costs, and meet consumer demands with confidence.

This E-Liquid filling machine is suitable for:

Daily chemistry, cosmetics. Smallglass bottles and plastic bottles such as electronic liquids, essential oils, syrups, etc.

This machine function is:

1. Man-machine dialogue system setting,visual convenient operation ,accurate filling level

2. The mainframe running speed is step frequency conversion.

3. The product quantity can be controlled.

4. Multi-failure prompt function (such as depression, no filling and no inserting plug etc).

5. Automatic stop function, if there is no filling, no inner plug in any rail, it may stop automatically.

This machine body made by stainless steel, and the working process is controlled by touch screen, and the filling volume is adjustable.

This machine is suitable for filling capping e-liquid bottle of various specifications. According to customer filling material viscosity to choose piston filling system or peristaltic pump filling system.

According to customer’s requirement, we will offer our technician for oversea to install and adjust machine , We provide the full-lifetime warranty consult with one year free accessories, even two years. If you need, we also can arrange the engineer to your factory do field installation guidance.

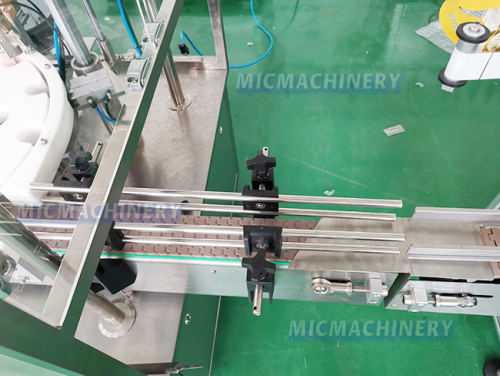

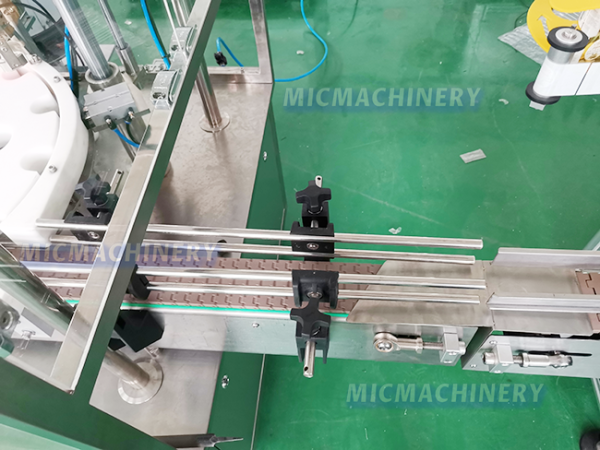

Conveyor belt

When the bottle is placed on it, the conveyor belt takes the bottle into the filling machine and starts filling. After filling, it is sent out through the conveyor belt. The whole process is convenient to save time.

This conveyor belt can be different size of bottle,The width between the two pipes can be adjusted according to your container,ensure smooth bottle safely from the conveyor belt moved .

on the side of the conveyor is equipped with sensors that can automatically identify when the bottle to go out or, in order to send signals to filling station of screw cap

Filling head

When the bottle through the conveyor belt was sent to the location of the chuck, automatic identification of sensors, control by internal program to send signals for filling station, when the bottle comes under the filling head, cylinder head began to move down the drive filling, filling process without dripping, do not waste material, also can ensure the bottle clean and tidy, convenient after labeling.

Automatic sorting device for the lid

Its main role is going to filling the bottle, hand put the bottle to the machine, open the bottle on the button on the touch screen, start automatically on the bottle, the bottle to the filling machine by the conveyor belt This process greatly save labor costs, and its work efficiency is very high, save time and effort.

If you want to know more models of filling machine, you can refer to the table below:

|

Vial Filling Machine |

||||||||

|

model |

FC-30 |

FC-X40 |

FC-P35 |

FC-P40 |

FC-T30 |

FC-N25 |

FC-E35 |

FC-Z40 |

|

application |

cosmetics, daily chemical and pharmaceutical industries such as nail polish, e-liquid, eye drop,etc |

|||||||

|

Packing type |

various round and flat glass and plastic bottles,etc |

|||||||

|

speed |

23-30 pcs/min |

30-50 pcs/min |

30-40 pcs/min |

25-30 pcs/min |

20-30 pcs/min |

15-25 pcs/min |

30-40 pcs/min |

30-50 pcs/min |

|

Filling arrange |

50-250ML |

10-100 ML |

10-100 ML |

10-100 ML |

30-120 ML |

2-30 ML |

10-100 ML |

20-150 ML |

|

power |

5kw |

2KW |

2KW |

5KW |

2KW |

2KW |

2KW |

2KW |

|

size |

2000*1000*1700mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

2000*1000*1500mm |

|

weight |

650KG |

550KG |

650KG |

650KG |

650KG |

650KG |

650KG |

600KG |

in short, we will try our best to provide you with satisfactory service,the following is our customer feedback.