- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the dynamic landscape of CBD manufacturing, precision and efficiency are paramount for meeting consumer expectations and ensuring product quality. Small bottle filling machines play a pivotal role in this domain, offering unmatched performance tailored to the exacting standards of the industry. Let's explore their significance, focusing on their role as CBD filling machines, automatic CBD filling machines, and filling machines for CBD oil.

Optimizing Filling Precision

Accurate Volume Dispensing: Small bottle filling machines are engineered to dispense CBD oil with exceptional precision, ensuring accurate filling volumes in each bottle. Equipped with advanced dosing mechanisms and precise controls, these machines guarantee consistency across production batches, maintaining product quality and consumer satisfaction.

High-Speed Operation: Designed for efficient CBD production, small bottle filling machines offer rapid filling speeds, maximizing throughput while minimizing production time. Their automated processes enable continuous filling, significantly reducing manual labor and increasing overall efficiency. With adjustable filling speeds and customizable settings, these machines adapt to the fast-paced demands of the CBD industry.

Versatility and Adaptability: Small bottle filling machines boast versatility in accommodating various bottle sizes, shapes, and materials commonly used in CBD packaging. Whether filling glass bottles, plastic containers, or squeeze tubes, these machines ensure seamless integration into diverse CBD product manufacturing processes. Their flexible design allows for quick changeovers between different bottle formats, facilitating production versatility and minimizing downtime.

Significance in CBD Product Manufacturing

CBD Filling Machine: Small bottle filling machines serve as essential tools in CBD product manufacturing, providing precise filling solutions for a wide range of CBD products. Whether filling CBD oil tinctures, capsules, or topicals, these machines ensure accurate dosing and uniform product presentation, contributing to consumer trust and brand reputation.

Automatic CBD Filling Machine: In the rapidly evolving CBD market, automatic small bottle filling machines streamline production workflows by automating the filling process. These machines offer hands-free operation, minimizing manual intervention and ensuring consistent filling results across production runs. With their high-speed capabilities and reliable performance, automatic filling machines optimize production efficiency and product quality.

Filling Machine for CBD Oil: Small bottle filling machines play a crucial role in filling CBD oil bottles and containers with precision and efficiency. By seamlessly integrating into CBD oil production lines, these machines enhance filling accuracy, minimize product waste, and ensure compliance with regulatory standards. Their performance contributes to the overall success and competitiveness of CBD oil brands in the market.

Conclusion

Small bottle filling machines represent indispensable assets in CBD product manufacturing, offering precision, efficiency, and versatility in filling operations. Whether as CBD filling machines, automatic CBD filling machines, or filling machines for CBD oil, their performance optimizes production processes, enhances product quality, and ensures regulatory compliance. By investing in these advanced filling solutions, CBD manufacturers can streamline their production workflows, meet market demands, and maintain a competitive edge in the rapidly growing CBD industry.

This E-Liquid filling machine is suitable for:

Daily chemistry, cosmetics. Smallglass bottles and plastic bottles such as electronic liquids, essential oils, syrups, etc.

This machine function is:

1. Man-machine dialogue system setting,visual convenient operation ,accurate filling level

2. The mainframe running speed is step frequency conversion.

3. The product quantity can be controlled.

4. Multi-failure prompt function (such as depression, no filling and no inserting plug etc).

5. Automatic stop function, if there is no filling, no inner plug in any rail, it may stop automatically.

This machine body made by stainless steel, and the working process is controlled by touch screen, and the filling volume is adjustable.

This machine is suitable for filling capping e-liquid bottle of various specifications. According to customer filling material viscosity to choose piston filling system or peristaltic pump filling system.

According to customer’s requirement, we will offer our technician for oversea to install and adjust machine , We provide the full-lifetime warranty consult with one year free accessories, even two years. If you need, we also can arrange the engineer to your factory do field installation guidance.

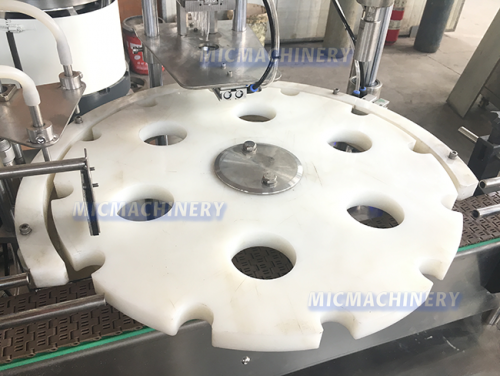

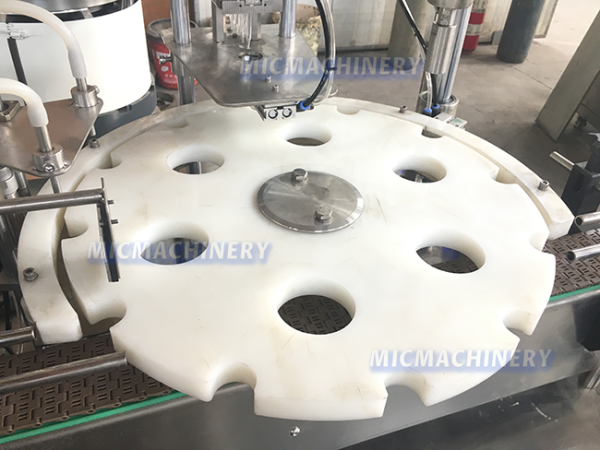

The main platform

The picture includes chuck, sensor.filling head,and automatic plug feeding and lid tightening stations.They are clear function and easy to clean.

Among them, the chuck is used to fix the filling container and drive the container to move to the filling、capping and other stations. The circular design can save space while setting up multiple positions, so that the filling process is time-saving and efficient

We can customize this turntable, filling head, screw cap and so on

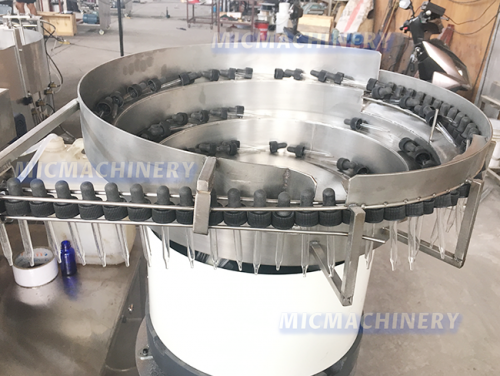

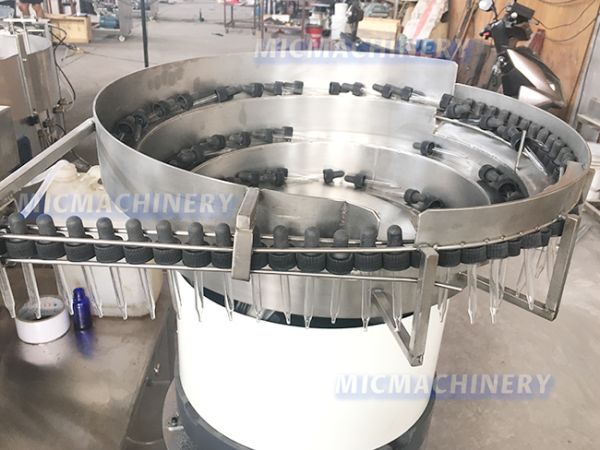

dropper loading automatically

Dropper feeding cage with vibrating disk is connected to a pipe that carries the dropper ,They automatically arranges the dropper and deliver the dropper.

In this way, the small bottle is covered in a consistent process, reducing the manual contact with the syringe process, and ensuring bottle hygiene,At the same time, labor costs are reduced.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback:er