- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the world of glass bottle packaging, precision and efficiency are key to maintaining product integrity and enhancing production processes. The 12-Heads Linear Glass Bottle Filling Machine serves as a crucial solution, offering meticulous and efficient filling for various liquid products. Let's delve into how this equipment performs, focusing on its role as a glass bottle filling machine, glass bottling machine, and glass bottle packing machine.

Maximizing Performance with 12-Heads Linear Glass Bottle Filling Machine

Accurate Filling Precision: The 12-Heads Linear Glass Bottle Filling Machine ensures precise and consistent filling for glass bottles. Equipped with twelve filling heads and advanced dosing controls, this equipment delivers uniform filling levels, minimizing product variations, and maintaining packaging integrity.

Enhanced Efficiency: Serving as a glass bottle filling machine, this equipment optimizes production efficiency by automating the filling process. Its linear design allows for simultaneous filling of multiple bottles, reducing cycle times and increasing throughput, thus enhancing overall productivity.

Versatile and Reliable Operation: As a glass bottle packing machine, the 12-Heads Linear Glass Bottle Filling Machine offers versatility and reliability. Its adaptable design accommodates various bottle shapes and sizes, catering to diverse packaging requirements while ensuring consistent performance levels.

Serving as a Glass Bottle Filling Machine, Glass Bottling Machine, and Glass Bottle Packing Machine

Glass Bottle Filling Machine: The 12-Heads Linear Glass Bottle Filling Machine serves as a dedicated solution for filling glass bottles. Its precise engineering and multi-head design ensure accurate dosing and efficient filling, making it an indispensable asset in glass bottle packaging operations.

Glass Bottling Machine: Specifically tailored for glass bottle applications, this equipment automates the bottling process, optimizing packaging efficiency. Its linear configuration enables seamless integration into production lines, maximizing throughput, and minimizing manual intervention.

Glass Bottle Packing Machine: With its comprehensive filling capabilities, the 12-Heads Linear Glass Bottle Filling Machine offers reliability in packing glass bottles. Whether filling beverages, condiments, or pharmaceuticals, this equipment delivers consistent and high-quality filling, meeting diverse market demands with precision and efficiency.

Glass Bottle Packing Machine: With its comprehensive filling capabilities, the 12-Heads Linear Glass Bottle Filling Machine offers reliability in packing glass bottles. Whether filling beverages, condiments, or pharmaceuticals, this equipment delivers consistent and high-quality filling, meeting diverse market demands with precision and efficiency.

Conclusion

The 12-Heads Linear Glass Bottle Filling Machine represents a fusion of precision, efficiency, and versatility in glass bottle packaging. Whether serving as a glass bottle filling machine, glass bottling machine, or glass bottle packing machine, it plays a crucial role in optimizing manufacturing processes and ensuring product quality. By investing in this advanced equipment, manufacturers can streamline operations, reduce costs, and meet consumer demands with confidence, thus securing a competitive edge in the market.

This machine is suitable for filling a liquid and cream products, especially for high viscosity materials, the effect is obvious.

1. Adopt PLC programmable control system with touch screen interface.

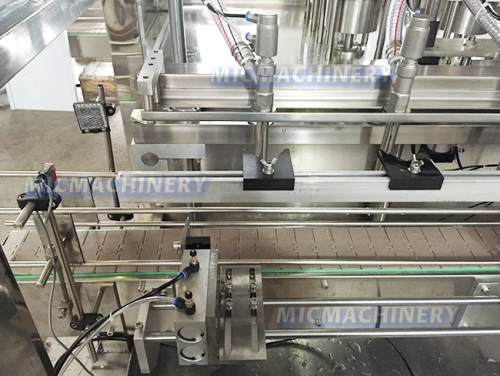

2. Automatic bottle feeding, automatic filling, automatic bottle.

3. Adopt servo motor drive, double screw-rod drive, Control the movement of the piston rod to ensure the stability of the filling.

4. Adopt double-ball screw rod filling the filling nozzle dive

5. It can be used with capping machine, labeling machine supporting the formation of the production line

6. It combines optical, mechanical, electrical, gas in one. It is easy to operate a filling machine.

7. Having a stable and reliable operation, high production efficiency, strong adaptability.

filling head

The liquid is put into the material cylinder, and the piston to pump the liquid into the measuring cylinder. Then the piston moves up to send the liquid to the filling pipe. At the same time, when the bottle enters the filling machine through the conveyor belt, the filling head moves down to start filling. After filling, the conveyor belt will automatically send the bottle to the capping station.

(Filling process without drip leakage, the number of filling head can be customized according to your needs and diameter of filling head basis on the diameter of your barrel’s mouth)

Measuring cylinder

The function of measuring cylinder cylinder is mainly quantitative filling, its use can make your filling accuracy higher, driven by servo motor, control the movement of the piston rod, the Piston moving down extract the material from the material cylinder to the measuring cylinder cylinder, and then the piston moves up to the dose of the cylinder cylinder in the material to the filling pipeline.

Heat preservation device is added outside the measuring cylinder, especially suitable for some materials that need high temperature filling.

(The size of dose cylinder can be customized according to your needs)

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed (basis on 50-500ml) |

1500 B/h |

2000B/h |

2500B/h |

3000 B/h |

4000B/h |

5000 B /h |

6000 B/h |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.5Kw |

3.6kw |

3.7kw |

3.8kw |

3.9Kw |

4.0Kw |

|

Size |

1000*480*700 mm |

1400*1450*2270 mm |

1400*1450*2270 mm |

1700*1450*2270 mm |

2000*1450*2270 mm

|

2300*1450*2270 mm |

2600 *1450*2270 mm |

|

Weight |

35 Kg |

500kg |

600kg |

700kg |

800Kg |

900 kg |

1000 kg |

in short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

Filling head

8 heads

Filling volume range

50-1000ml(Use 1000ml piston cylinder)

Production speed

≤1800 Bph basis on 1000ml bottle

Voltage

220v/380v

Power

3kw

Suitable bottle’s diameter

Ф40mm-Ф100mm

Filling error

≤±1

Work pressure

0.55Mpa-0.65Mpa

Size

2000mm × 1400mm× 2500mm

Weight

1000kg

|

Touch screen |

Canada xinjie color |

|

PLC |

Schneider |

|

Solenoid valve |

Taiwan Airtac |

|

Optoelectronic system |

OPTEX |

|

Micro differential pressure switch |

Netherlands |

|

Servo motor |

Taiwan TECO |

|

Air source treatment |

Taiwan Airtac |

|

Button and low voltage electric appliance |

Schneider |

|

Ball screw |

Taiwan |

|

Reducer |

Taiwan VGM |

|

Switching power supply |

Taiwan meanwell |

|

Material |

Contact with the material parts of the 316 materials, and the rest of the 304 stainless steel |