- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

It can be widely used in chemical, food, light industry, pharmaceutical, building materials and other industries.

Proction Interduction:

a. Integrate mixture, dispersion and wall scraper in one machine.

b. Mechanical seal, O ring seal or trapezoid seal for option material reaction can happen under vacuum condition.

c. High and low speed impellers rotate rapidly and exert strong impact force to mix materials thoroughly in a very short time. No deposit and residuals.

d. Inverter control, various speed adjustment.

e. Mirror polishing to ensure its smoothness.

If you are interested in this machine,please contract us.We will be glad to recieve your inquiry.

Versatile Mixing Solutions for Pharmaceutical Formulations:

planetary mixer in pharmaceutical industry in pharmaceutical industry have garnered widespread recognition for their versatility in handling various pharmaceutical formulations. These mixers employ a unique mixing action that combines rotation and revolution, enabling thorough blending of ingredients. With the ability to accommodate different viscosities and consistencies, planetary mixers are capable of effectively handling powders, granules, pastes, creams, gels, and other pharmaceutical formulations. This versatility makes them indispensable for applications such as tablet manufacturing, capsule filling, cream compounding, ointment production, and more.

Achieving Uniform Dispersion of Active Ingredients:

Ensuring the uniform dispersion of active ingredients is a critical aspect of pharmaceutical manufacturing, directly impacting the potency and efficacy of the final product. planetary mixer in pharmaceutical industry excel in achieving this goal by efficiently dispersing and blending active ingredients with other components, including fillers, binders, lubricants, and disintegrants. The precise mixing action of planetary mixers promotes a homogeneous blend, resulting in consistent quality and optimal performance of pharmaceutical formulations.

Optimized Processing Time and Enhanced Efficiency:

In the fast-paced realm of pharmaceutical production, minimizing processing time is paramount. planetary mixer in pharmaceutical industry in pharmaceutical industrys offer efficient mixing capabilities, leading to reduced overall processing time required for blending pharmaceutical ingredients. By utilizing a combination of planetary motion, powerful motors, and purpose-designed mixing tools, these mixers enable rapid and thorough mixing, resulting in improved production efficiency and increased throughput.

Compliance with Regulatory Standards and Quality Assurance:

Pharmaceutical manufacturing operates under stringent regulations and adheres to high-quality standards, including Good Manufacturing Practices (GMP). planetary mixer in pharmaceutical industry are designed to meet these exacting requirements, providing features that ensure compliance and enhance quality assurance. Features such as easy-to-clean surfaces, sealed mixing vessels, and sanitary designs facilitate thorough cleaning, prevent cross-contamination, and promote product safety. Additionally, advanced control systems enable precise monitoring and adjustment of mixing parameters, ensuring consistent quality throughout the production process.

Integrate mixture, dispersion and wall scraper in one machine.

Mechanical seal, O ring seal or trapezoid seal for option material reaction can happen under vacuum condition.

High and low speed impellers rotate rapidly and exert strong impact force to mix materials thoroughly in a very short time. No deposit and residuals.

Inverter control, various speed adjustment.

Mirror polishing to ensure its smoothness.

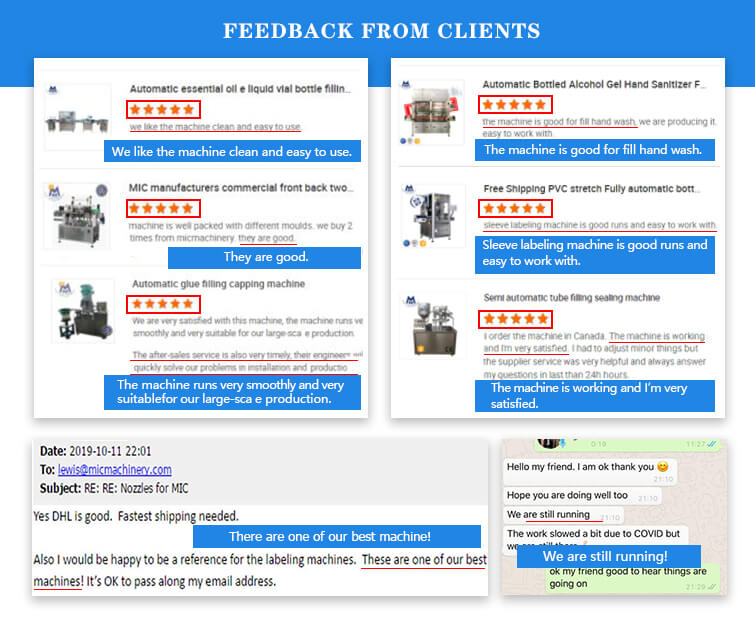

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Valtage |

220V |

|

Power |

45KW |

|

Material Barrel Design Volume |

650L |

|

Material Barrel Working Volume |

500L |

|

Vacuum Degree |

-0.08Mpa |

| Stitting Shaft Speed | 0-55rpm suitable |

|

Frequency Changer |

Watson (Shenzhen) |

| Motor | Kiper (Wuxi) |

| Reducition Gears |

Kiper (Wuxi) |

| Vacuum Pump | Maubec (Shenzhen) |

| 316 Stainless Steel | Tisco (Taiyuan) |

| 304 Stainless Steel | Tisco (Taiyuan) |

| Main Electrical Components | Chint (Zhejiang) |

| Bearing | NSK (Japan) |

| Sealing Element | Dingsheng (Taiwan) |