- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

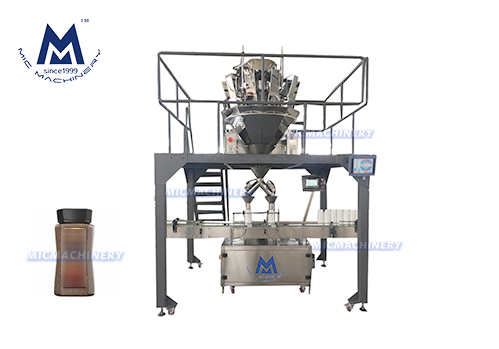

In the vibrant world of culinary innovation, where flavors dance and aromas captivate, the Spice Filling Machine emerges as an essential partner for spice producers and culinary enthusiasts. This advanced device embodies precision and efficiency, redefining the way spices are packaged and delivered to kitchens around the globe. By exploring its unique product characteristics, versatile applications, and the intricate mechanical principles guiding its operation, one can truly grasp its pivotal role in the food industry. From spice manufacturing facilities to gourmet restaurants, this machine ensures that every packet and jar is filled with the authentic essence of spices, enhancing culinary experiences with each sprinkle and pinch.

Product Characteristics:

The Spice Filling Machine is defined by an array of exceptional product characteristics designed for accuracy and consistency. Crafted from high-quality stainless steel and food-grade materials, these machines guarantee durability, hygiene, and compliance with stringent food safety standards. Their adaptable design allows for customizable filling options, accommodating various spice textures and densities, catering to the diverse needs of spice producers. Equipped with precision dosing systems, these machines ensure accurate filling, minimizing wastage and optimizing resource utilization. Anti-clumping mechanisms and dust control features maintain the freshness and potency of the spices, ensuring a high-quality end product for consumers.

Product Applications:

The applications of the Spice Filling Machine are vast and indispensable within the food industry. Spice manufacturers rely on these machines to maintain the consistency and quality of their spice blends, ensuring accurate portions and preserving the aromatic profiles. Gourmet restaurants and food packaging companies utilize these machines to enhance the presentation and quality of their products, meeting the discerning tastes of culinary enthusiasts. Additionally, these machines are invaluable for catering services, spice subscription boxes, and specialty food stores, providing consumers with precisely filled spice packets and jars. The adaptability of these machines allows spice producers to offer a wide range of products, from exotic spice blends to single-origin varieties, catering to the diverse palates of home cooks and chefs.

Mechanical Principle:

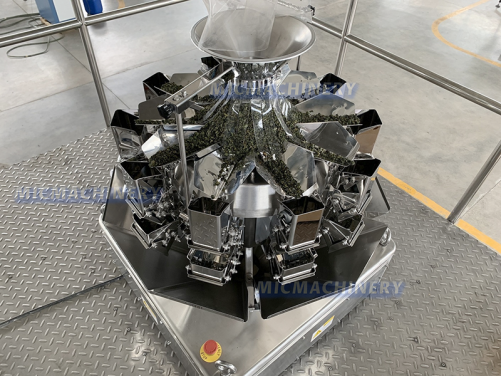

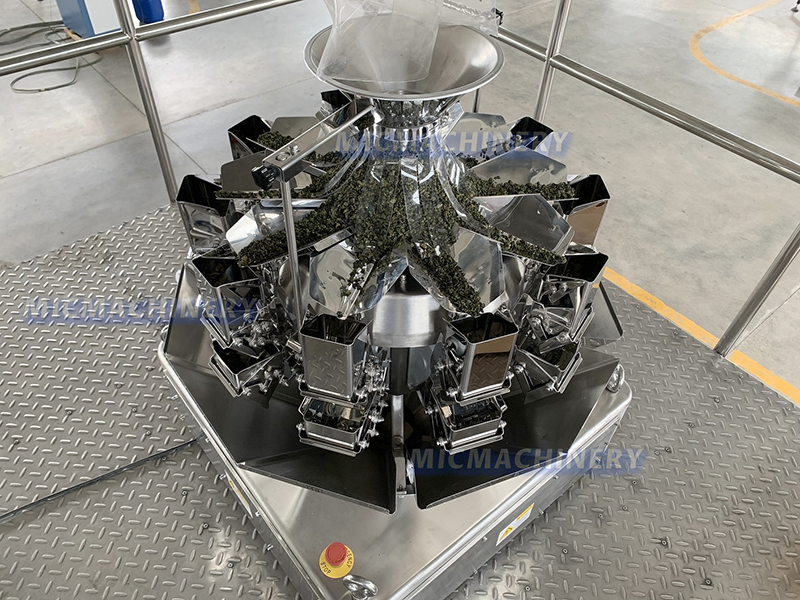

At its core, the Spice Filling Machine operates on intricate mechanical principles designed for precision and speed. Utilizing auger systems, vibratory feeders, and weighing scales, the machine accurately measures and dispenses the specified quantity of spices into individual packets or jars. Sealing mechanisms, employing heat or pressure technology, secure the packaging, preserving the freshness and flavor of the spices. Integrated sensors and programmable logic controllers (PLCs) oversee the entire process, ensuring uniformity, minimizing errors, and enhancing the overall efficiency of the filling operation.

In conclusion, the Spice Filling Machine stands as a testament to culinary precision and innovation. Its exceptional product characteristics, diverse applications, and advanced mechanical principles make it an indispensable asset for spice producers, gourmet chefs, and food enthusiasts alike. Embracing the latest technological advancements, this machine not only ensures the accuracy of spice portions but also upholds the highest standards of flavor and aroma, enriching culinary creations and delighting taste buds, making it an essential component in the ever-evolving world of culinary arts and gastronomy.

2.Frequency conversion adjusts the speed: this machine uses frequency conversion equipment, can be adjusted within the range according to the needs of reality in production

3.Automatic checking: no pouch or pouch open error, no fill, no seal. the bag can be used again, avoid wasting packing materials and raw materials.

4.Safety device: Mchine stop at abnormal air pressure, heater disconnection alarm。

5.Horizontal conveyer style to giving bag: it can put on more bags on the bag storage and have a low requirement about the quality of bags.

6.The width of the bags could be adjusted by electrical motor. Press the control-button could adjust the width of clips, easily operate, and save time.

7.It match with the glass safety door. The machine will stop working when you open the door. So that it could protect the safety of operators. At the same time, it could prevent dust.8.Use the plastic bearing, don’t need put on oil, less pollution.

9.Use no oil vacuum pump, avoid polluting the environment in the production.

10.The opening zipper framework is special in the feature of zipper bag, it can avoid distortion or destroy when open the zipper

11.The packing materials loss low, what this machine is used the preformed bag, the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification

12.Product or packing bag contact parts adopt stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food13.With different feeders changed to pack solid, liquid, thick liquid ,powder and so on

14. The packing bag suits in extensive range, suit for multi-layer compound, monolayer PE , PP and so on Preformed bag made by film and paper.