- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

In the fast-paced world of tea production, efficiency and precision are paramount. Enter the revolutionary solution: the Tea Bag Filling Machine. This cutting-edge marvel combines advanced technology with ingenuity, revolutionizing the way tea is packaged and processed. Let’s delve into its product characteristics, versatile applications, and the intricate mechanical principles that make it an indispensable asset in the tea industry.

Product Characteristics:

Tea bag filling machines stand as epitomes of innovation, boasting a plethora of distinctive characteristics. These machines are engineered with high-grade materials, ensuring durability and longevity. Their modular design facilitates easy customization, accommodating diverse tea blends and bag sizes. Precise weight control mechanisms guarantee consistent filling, maintaining the quality and flavor integrity of every tea bag. Moreover, these machines often incorporate user-friendly interfaces, enhancing operational efficiency and minimizing downtime.

Product Applications:

The applications of tea bag filling machines are as diverse as the tea blends they handle. From traditional loose leaf teas to herbal infusions and aromatic blends, these machines cater to a wide spectrum of tea varieties. Ideal for both small-scale artisanal producers and large-scale tea manufacturing plants, these machines streamline the packaging process, ensuring uniformity and enhancing the visual appeal of the final product. Restaurants, cafes, and retail outlets also benefit from the efficiency of these machines, meeting the demands of tea enthusiasts worldwide.

Mechanical Principle:

At the heart of tea bag filling machines lies a sophisticated mechanical principle. Utilizing precision dosing systems, these machines measure and dispense precise quantities of tea into individual bags. The process involves a delicate interplay of conveyors, hoppers, and filling chambers, orchestrated with meticulous precision. Automated sensors and actuators ensure seamless operation, while advanced sealing mechanisms secure the tea bags, preserving freshness and flavor. Through a combination of mechanical accuracy and technological finesse, these machines transform raw tea leaves into conveniently packaged delights.

In conclusion, the Tea Bag Filling Machine represents a paradigm shift in the tea industry, embodying innovation, efficiency, and quality. Its remarkable product characteristics, diverse applications, and intricate mechanical principles underscore its significance, making it an indispensable tool for tea producers and enthusiasts alike.

This machine is suitable for automatic packaging of liquid of foods, medicine and chemicals,such as pesticide,shampoo,body foam bath lotion, facial cream, ingredient oil, fruit sauce,tomato ketchup and honey shower gel, skin lotion, toothpaste, cosmetic cream, fruit jam, edible oil, soy etc .

Machine features:

1. This machine can finish : forming bag--measuring--material filling—sealing—counting—date code printing, all the work automatically;

2. Photoelectric and tracing system or computer system can be provided without your specific requirements.

3. The PLC controller has the advantages such as setting the length of the bag; the out put alarm and the speed and quantity with buttons;

4. This machine can be installed to code printer for 1-3 lines characters such as production and expiry date according to your special request.

5.Eye Mark System ,machine can cut complete logo.

6.Machine Stop Automaticlly if it is out of film.

7.Fine Packaging performance.low noies .clear sealing texture and strong sealing performacnce.

Applicable packing film:

Paper/PE, PT/PE, PET/AL/PE, BOPP/PE, Tea filter paper and other compound materials can be heat sealed.

Control Panel

The control panel on the filling machine is the core of the machine,it consists of touch screen,power switch, emergency button You just need to press the corresponding button and the machine will follow the correct program.

The PLC controller has the advantages such as setting the length of the bag; the out put alarm and the speed and quantity with buttons;

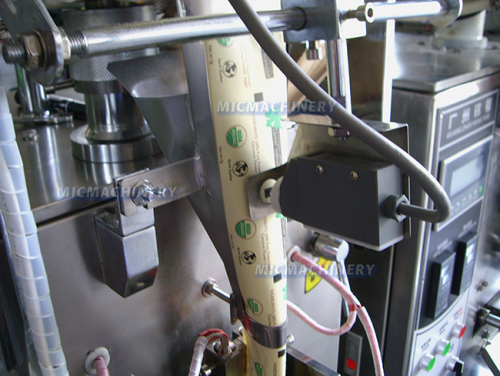

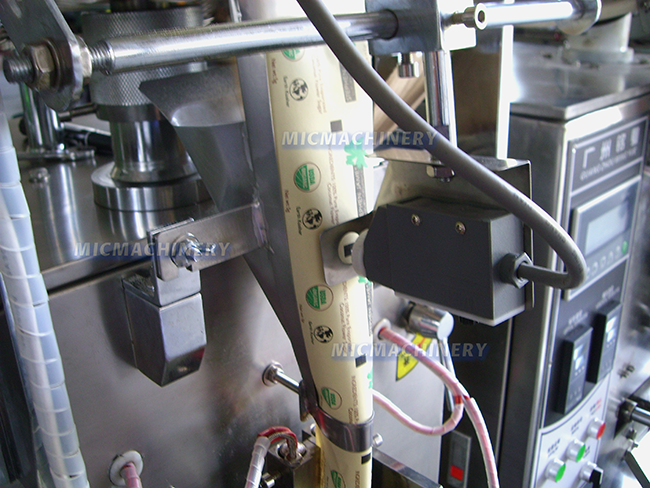

Sensor

The sensor senses the location of the film, telling the machine where to cut the bag.Photoelectric and tracing system or computer system can be provided without your specific requirements.

Bag Former

This machine can finish forming bag--measuring--material filling—sealing—counting—date code printing, all the work automatically;Fine Packaging performance.low noies .clear sealing texture and strong sealing performacnce.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

MIC V01 |

MIC-ZF4 |

MIC-ZF6 |

MIC-ZF8 |

MIC-ZF12 |

MIC-ZF16 |

MIC-ZF20 |

|

Application |

High Viscosity Materials,Butter,Mayonnaise,Honey,Tomato Sauce,Cream , Liquid soap , oil product ,Lotion And So On |

||||||

|

Packing Type |

Metal Cans, jar, Glass Bottle , Bag, Plastic Bottle Etc |

||||||

|

Speed |

5-25 B/M |

192-220 B/h (basis on 25L) |

1300-1500 B/h (basis on100ml bottle) |

≤1800 B/h ( basis on 1000ml bottle) |

3000B/h (basis on 350ml) |

3200 B /h |

≤4000 B/h (basis on1L bottle) |

|

Filling Arrange |

10-20ML. 25-250ML. 50-1000ml, 50-500ML.100-1000ML.250-2500ML. 1000-5000ML 100ml-5L.(10ml-5l) |

||||||

|

Power |

30W |

3.0Kw |

2.8kw |

3kw |

2.8kw |

2Kw |

3.0Kw |

|

Size |

1000*480*700 mm |

2500*1600*2500 mm |

1840*1400*2500 mm |

2000*1400*2500 mm |

1600*1400*2300 mm

|

2440*1240*2350 mm |

2800 *1400*2500 mm |

|

Weight |

35 Kg |

700 kg |

600kg |

1000kg |

3000Kg |

700 kg |

1000 kg |

In addition to,If you're looking for sauce filling machine,tomato sauce filling machine,chili sauce filling machine,hot sauce filling machine,mayonnaise filling machine,tomato paste filling machine,hot sauce bottle filling machine,sauce bottle filling machine,automatic sauce filling machine,sauce filling machine price,it is a pleasure for you to visit our website anytime.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback: