- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

In the realm of dairy processing, where freshness meets technology, the Yogurt Packaging Machine emerges as a symbol of precision and efficiency. This cutting-edge device seamlessly blends the wholesome goodness of yogurt with modern engineering, revolutionizing the way this beloved dairy product is packaged and delivered to consumers worldwide. By exploring its unique product characteristics, diverse applications, and the intricate mechanical principles guiding its operation, one can truly grasp its pivotal role in the food industry. From dairy farms to supermarket shelves, this machine ensures that every yogurt cup is sealed with the richness and freshness of dairy delight.

Product Characteristics:

The Yogurt Packaging Machine boasts exceptional product characteristics tailored for reliability and consistency. Crafted from food-grade stainless steel and advanced polymers, these machines guarantee durability, hygiene, and compliance with stringent food safety standards. Their adaptable design allows for customizable packaging options, accommodating various cup sizes and yogurt consistencies, catering to the diverse needs of dairy producers. Equipped with precision dosing systems and sealing mechanisms, these machines ensure accurate and mess-free filling, minimizing wastage and optimizing resource utilization. User-friendly interfaces enhance operational efficiency, allowing for seamless adjustments and control, ensuring each cup is sealed to perfection.

Product Applications:

The applications of the Yogurt Packaging Machine are vast and indispensable within the food industry. Dairy farms and yogurt producers rely on these machines to maintain the freshness and quality of their products, ensuring a longer shelf life and superior taste. Large-scale production facilities utilize these machines to streamline their packaging processes, enhancing productivity while maintaining the integrity of their dairy offerings. Additionally, these machines are vital for catering services, airlines, and institutional food providers, ensuring a convenient and hygienic delivery of yogurt products to consumers. The versatility of these machines allows dairy producers to offer various yogurt flavors, sizes, and packaging styles, catering to the diverse tastes of consumers.

Mechanical Principle:

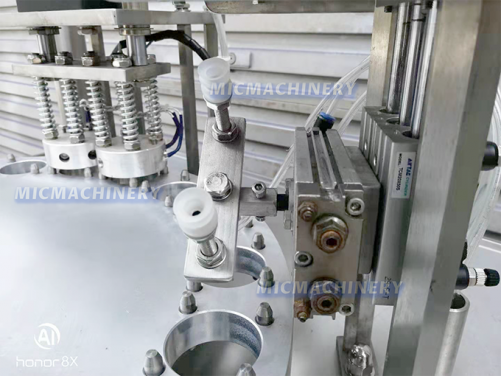

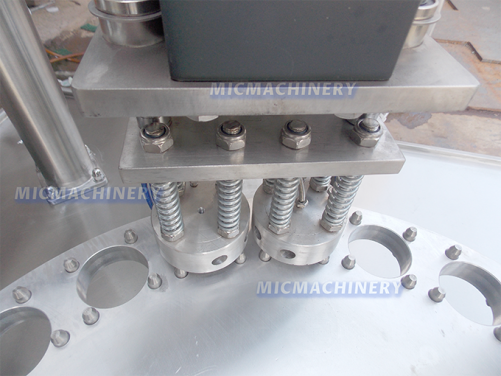

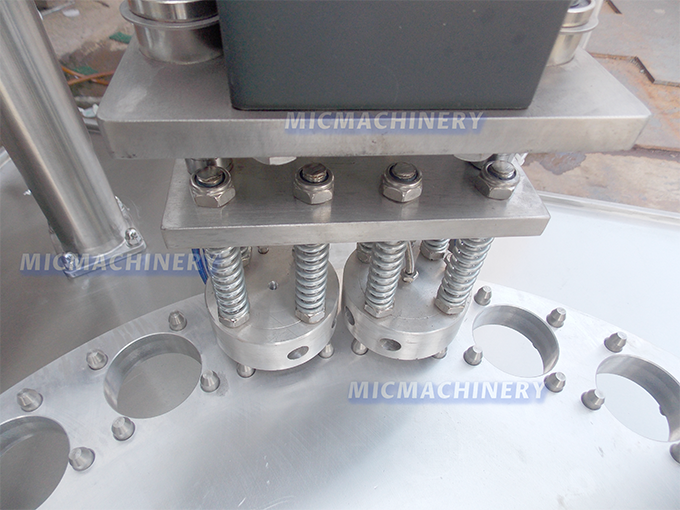

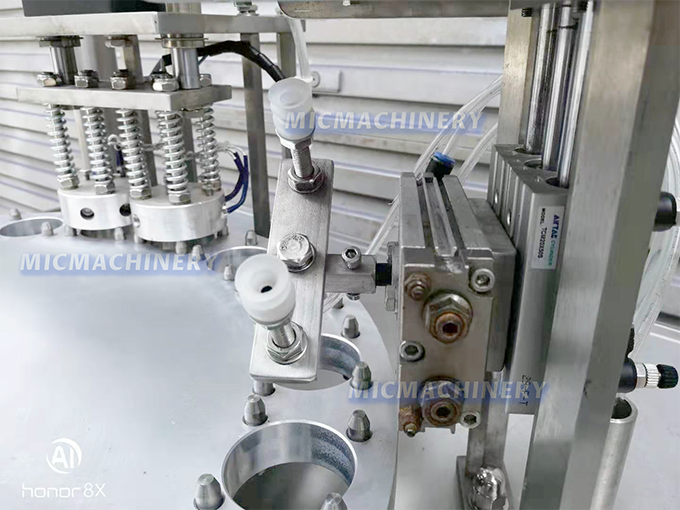

At its core, the Yogurt Packaging Machine operates on sophisticated mechanical principles designed for precision and speed. Utilizing conveyor systems, dosing pumps, and sealing stations, the machine accurately measures and dispenses the specified quantity of yogurt into individual cups. Automated sealing mechanisms, employing heat or pressure technology, secure the cups, preserving the freshness and flavor of the yogurt. Integrated sensors and programmable logic controllers (PLCs) oversee the entire process, guaranteeing accuracy, minimizing errors, and enhancing the overall efficiency of the packaging operation.

In conclusion, the Yogurt Packaging Machine represents the epitome of innovation and reliability in the food industry. Its exceptional product characteristics, diverse applications, and advanced mechanical principles make it an indispensable asset for dairy producers and food manufacturers alike. Embracing the latest technological advancements, this machine not only ensures the freshness and quality of yogurt products but also upholds the highest standards of food safety, making it an essential component in the dairy processing landscape, where precision and taste harmonize to create a delightful consumer experience.

In the realm of dairy processing, where freshness meets technology, the Yogurt Packaging Machine emerges as a symbol of precision and efficiency. This cutting-edge device seamlessly blends the wholesome goodness of yogurt with modern engineering, revolutionizing the way this beloved dairy product is packaged and delivered to consumers worldwide. By exploring its unique product characteristics, diverse applications, and the intricate mechanical principles guiding its operation, one can truly grasp its pivotal role in the food industry. From dairy farms to supermarket shelves, this machine ensures that every yogurt cup is sealed with the richness and freshness of dairy delight.

Product Characteristics:

The Yogurt Packaging Machine boasts exceptional product characteristics tailored for reliability and consistency. Crafted from food-grade stainless steel and advanced polymers, these machines guarantee durability, hygiene, and compliance with stringent food safety standards. Their adaptable design allows for customizable packaging options, accommodating various cup sizes and yogurt consistencies, catering to the diverse needs of dairy producers. Equipped with precision dosing systems and sealing mechanisms, these machines ensure accurate and mess-free filling, minimizing wastage and optimizing resource utilization. User-friendly interfaces enhance operational efficiency, allowing for seamless adjustments and control, ensuring each cup is sealed to perfection.

Product Applications:

The applications of the Yogurt Packaging Machine are vast and indispensable within the food industry. Dairy farms and yogurt producers rely on these machines to maintain the freshness and quality of their products, ensuring a longer shelf life and superior taste. Large-scale production facilities utilize these machines to streamline their packaging processes, enhancing productivity while maintaining the integrity of their dairy offerings. Additionally, these machines are vital for catering services, airlines, and institutional food providers, ensuring a convenient and hygienic delivery of yogurt products to consumers. The versatility of these machines allows dairy producers to offer various yogurt flavors, sizes, and packaging styles, catering to the diverse tastes of consumers.

Mechanical Principle:

At its core, the Yogurt Packaging Machine operates on sophisticated mechanical principles designed for precision and speed. Utilizing conveyor systems, dosing pumps, and sealing stations, the machine accurately measures and dispenses the specified quantity of yogurt into individual cups. Automated sealing mechanisms, employing heat or pressure technology, secure the cups, preserving the freshness and flavor of the yogurt. Integrated sensors and programmable logic controllers (PLCs) oversee the entire process, guaranteeing accuracy, minimizing errors, and enhancing the overall efficiency of the packaging operation.

In conclusion, the Yogurt Packaging Machine represents the epitome of innovation and reliability in the food industry. Its exceptional product characteristics, diverse applications, and advanced mechanical principles make it an indispensable asset for dairy producers and food manufacturers alike. Embracing the latest technological advancements, this machine not only ensures the freshness and quality of yogurt products but also upholds the highest standards of food safety, making it an essential component in the dairy processing landscape, where precision and taste harmonize to create a delightful consumer experience.

Brief Introduction of Yogurt Packaging Machine:

It uses the piston cylinder to fill the material in the glass. It can be used in food, chemical industry, medicine, cosmetics, pesticides and other industries. It can be used for filling liquids, especially high viscosity materials and foaming liquids, such as yogurt, soy sauce, jam, soy sauce, ketchup, honey, butter, lubricating oil, etc. It uses PLC control. It fixes the discharge port according to the filling cup, and the rest of operations can be completed on the touch screen. It not only has the common characteristics of automatic piston filling machine, but also expands the range of filling materials. Just as the filler material contains particles, solid strips can also be very useful fillers.

Six Competitive Edges of Our Yogurt Packaging Machine:

1.We provide high-quality after-sales service.2.It can be used with standard conveyor belt or pucks for unstable cups.

3.Design flexible.

4.Format size conversion is very fast and easy

5.We can connect you with the model of the gas station.

6.The filling nozzle is drip proof.

Communication:

1.We will prepare various information and introduce you to videos, pictures and how the machine works.2.To ensure that we provide you with the right machines and solutions, we may ask you a lot about your needs.

3.We will give you samples to confirm the machine and production before we produce the machine.

4.We will test your machine with your real products, debug the machine until you are satisfied with the machine, and solve various problems of the machine.

5.We will help you in shipment and customs clearance and arrange affordable and safe shipping agents.