- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Embark on a journey of precision and efficiency with the Adhesive Filling Machine—a technological marvel that redefines the standards of adhesive packaging. This specialized equipment, celebrated for its unique product characteristics, versatile applications, and sophisticated mechanical principles, stands as an integral player in the adhesive industry. In this exploration, we unravel the essence of the Adhesive Filling Machine, showcasing its pivotal role in delivering reliable and consistent adhesive solutions.

Product Characteristics:

The Adhesive Filling Machine is distinguished by a set of exceptional product characteristics meticulously designed for efficiency and precision. Crafted from durable and corrosion-resistant materials, this machine ensures longevity in the demanding adhesive production environment. Automated filling, precise dispensing, and sealing mechanisms mark it as a pinnacle of speed and accuracy in adhesive packaging. Equipped with intuitive interfaces and advanced programmable controls, the machine seamlessly adapts to various adhesive viscosities and container sizes. Anti-drip features and customizable settings guarantee the preservation of adhesive quality, delivering products that embody efficiency and the promise of superior bonding performance.

Product Applications:

The versatility of the Adhesive Filling Machine extends across the adhesive and bonding sector, offering a streamlined solution for efficiently filling various adhesive formulations. Whether manufacturing instant adhesives, industrial glues, or specialized compounds, this machine ensures uniformity in dosage and presentation. Its adaptability addresses the dynamic requirements of the adhesive industry, where each adhesive variant demands a precise approach to dispensing, sealing, and preserving its unique properties. From large-scale industrial bonding applications to intricate crafts, the Adhesive Filling Machine plays a pivotal role in delivering potent and effective adhesive solutions.

Mechanical Principle:

At its core, the Adhesive Filling Machine operates on advanced mechanical principles meticulously designed for precision, speed, and reliability. Leveraging state-of-the-art volumetric or gravimetric filling systems, specialized nozzles, and sealing mechanisms, the machine accurately measures and dispenses the specified quantity of adhesive formulations into individual containers. Fully automated sealing ensures a secure, consistent, and airtight closure, preserving the potency and integrity of the adhesive product. Integrated sensors and programmable logic controllers (PLCs) oversee the entire process, ensuring seamless uniformity, minimizing errors, and enhancing the overall efficiency of adhesive filling operations.

In conclusion, the Adhesive Filling Machine stands as a cornerstone in the adhesive technology landscape, ensuring the efficient and accurate packaging of essential adhesive formulations. Its exceptional product characteristics, diverse applications, and advanced mechanical principles make it an indispensable asset for manufacturers globally. This machine continues to redefine the standards for adhesive filling, embodying the essence of precision and the commitment to superior bonding performance across various applications.

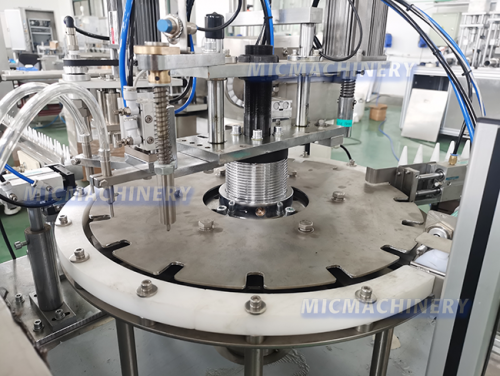

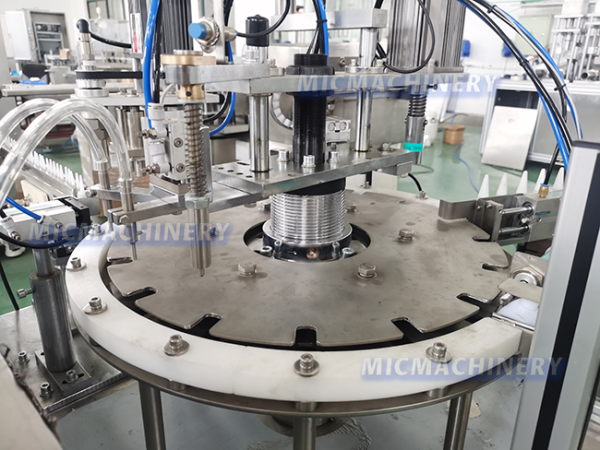

The main platform

The picture includes turnplate, filling head,and automatic cap feeding and cap tightening stations.They are clear function and easy to clean.

Among them, the mould is used to fix the filling container and drive the container to move to the filling、capping and other stations. The circular design can save space while setting up multiple positions, so that the filling process is time-saving and efficient

We can customize this turntable, filling head, screw cap and so on

Screw capping head

His job is to tighten the lid on a bottle that has been filled , which is the last step on the main bench.

When the bottle reaches under the Screw capping head, the machine automatically recognizes and the Screw capping head moves downward to tighten the cap quickly.

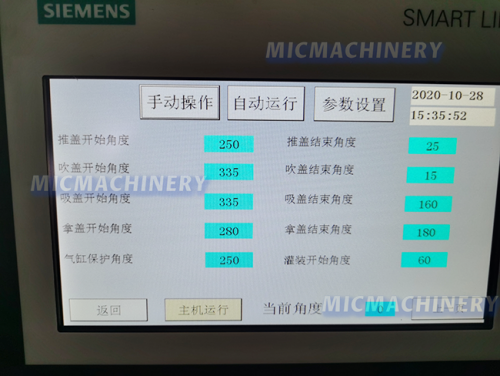

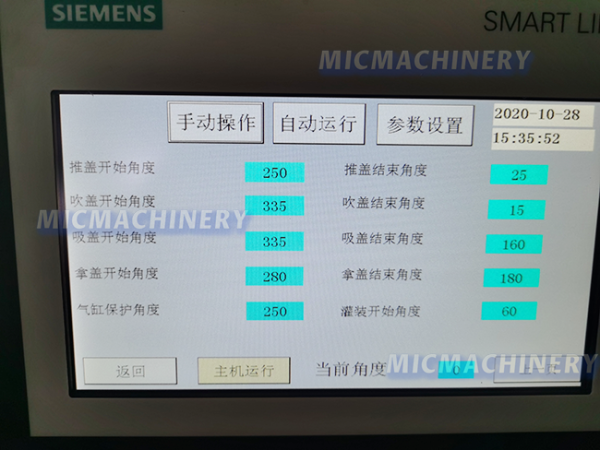

Control panel

The control panel on the filling machine is the core of the machine,it consists of touch screen,power switch, emergency button You just need to press the corresponding button and the machine will follow the correct program.

An Alarm Screen will also be included on automatic filling equipment to notify packagers when there is an issue with the filling equipment or the packaging line in general. In addition to notification, the screen can assist with identifying the issue if the same is not immediately obvious.

super glue, glue 502, cyanoacrylate adhesive and other similar products.

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand.

3) Running in a high automatization ,no pollution.

4) Self bottle loaded.

5) Stainless steel body, neat and beautiful.

6) No bottle no filling.

This machine filling system is made for specially for glue, easy clean and changes, it is a practical machine for glue production, 24 hours runs none stops, hardly have machine break down once well adjusted.

Machine filling accuracy max is at 0.3-0.7g, from 20ml-150ml.

This machine is adopted with mechanical hand to place inner and outer caps with no mistakes, capping noise is low enough to hear, capping divider speed reaches 60 piece per min, compare to other usually company, we can really do 60 piece per min, not just design theory.

This machine is guaranteed for one year and you can extent your guarantee easily by discuss with our sales.

Which you might be interested, under guaranteed, machine parts got broken by daily use, we will replace it once we are informed by free DHL.