- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

Product Characteristics:

The Automatic Glue Filling Machine is characterized by a set of remarkable features meticulously crafted for efficiency and precision. Constructed from robust materials, often incorporating corrosion-resistant components, it ensures durability and resilience in the challenging adhesive production environment. Automated filling, precise dispensing, and sealing mechanisms define this machine, positioning it as a pinnacle of speed and accuracy in glue packaging. Equipped with intuitive interfaces and advanced programmable controls, it seamlessly adapts to various adhesive viscosities and container sizes. Anti-drip features and customizable settings assure the preservation of adhesive quality, delivering products that embody efficiency and the assurance of superior bonding performance.

Product Applications:

The versatility of the Automatic Glue Filling Machine extends across the adhesive and bonding sector, offering a streamlined solution for efficiently filling various adhesive formulations. Whether manufacturing instant adhesives, industrial glues, or specialized compounds, this machine ensures uniformity in dosage and presentation. Its adaptability caters to the dynamic demands of the adhesive industry, where each glue variant requires a precise approach to dispensing, sealing, and preserving its unique properties. From large-scale industrial bonding applications to intricate crafts, the Automatic Glue Filling Machine plays a pivotal role in delivering potent and effective adhesive solutions.

Mechanical Principle:

At its core, the Automatic Glue Filling Machine operates on advanced mechanical principles meticulously designed for precision, speed, and reliability. Leveraging state-of-the-art volumetric or gravimetric filling systems, specialized nozzles, and sealing mechanisms, the machine accurately measures and dispenses the specified quantity of adhesive formulations into individual containers. Fully automated sealing ensures a secure, consistent, and airtight closure, preserving the potency and integrity of the adhesive product. Integrated sensors and programmable logic controllers (PLCs) oversee the entire process, ensuring seamless uniformity, minimizing errors, and enhancing the overall efficiency of glue filling operations.

In conclusion, the Automatic Glue Filling Machine stands as a beacon of innovation in the adhesive technology landscape, ensuring the efficient and precise packaging of essential adhesive formulations. Its exceptional product characteristics, diverse applications, and advanced mechanical principles make it an indispensable asset for manufacturers globally. This machine continues to set new standards for automatic glue filling, embodying the essence of precision and the commitment to superior bonding performance in various applications.

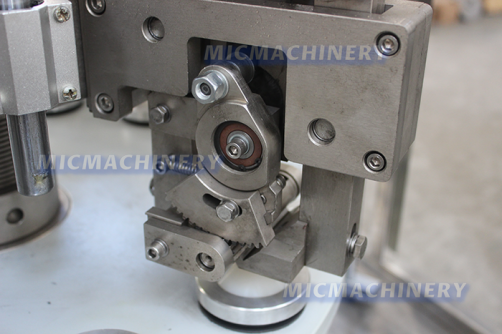

Sensor and Sensor rod

Main role is to sense the tube, and automatically turn the tube to ensure the standard.

Workflow: When the tube enters the machine bench, the sensor is automatic, adjusts the position of the pipe, and sends a signal to the next filling station. The internal program controls automatic filling

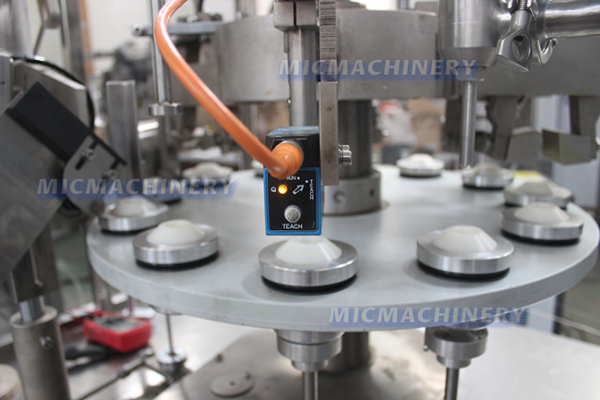

The main platform

The picture includes turntable, filling head,sensor,automatic flattened, fold-tube, cut and date-printed stations.This is clear function and easy to clean.

Main workflow: automatically goes on the tube. When the tube comes, the sensor automatically identifies it, sends a signal to the filling station, and starts the filling.After the filling, the tail of the pipe is flattened, folded, folded forward and back, date printed, and finally the pipe is topped out

We can customize this turntable, filling head, and so on

Automatic tube feeding system

Its main function is to make the pipes in order on the top, into the filling machine, the whole process can be controlled by the touch screen, the internal program will automatically complete the tube work. Effectively save labor cost

This machine function is:

1. Automatic tube clamping and sealing

2. Automatic tube loading tunnel

3. Automatic tube logo marking

4. Automatic material feeding system (optional)

5. No tubes no fill and date printing

6. Can equipped nitrogen filling system, and tube lifting filling system.

7. As different material, we can also make sure no air inside products while filling.

8. Automatic counting and tube outlet

9. Can be customized for different tube and liquid

10. Can be equipped different tanks and mixers

This MIC-L60 AUTO ALUMINUM TUBE FILLING & SEALING MACHINE is pneumatic controlled, with 1 filling head and a heating gun. It has total 10 positions for filling and sealing. And materials such as paste, adhesives, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste etc., are all applicable.

This machine is guaranteed for one year and you can extent your guarantee easily by discuss with our sales.

Which you might be interested, under guaranteed, machine parts got broken by daily use, we will replace it once we are informed by free DHL.

If you want to know more models of filling machine, you can refer to the table below:

|

Model |

L30 |

L30I |

L45 |

L45I |

L60 |

L60I |

R30 |

R30I |

R45 |

R60 |

|

Application |

Pharmacy, cosmetic, food and chemical ,super glue, glue 502. etc. |

|||||||||

|

Packing Type |

Soft tube,aluminum tube,plastic tube. Etc |

|||||||||

|

Speed |

10-50 t/m |

25-45 t/m |

30-75 t/m |

40-45 t/m |

50-60 t/m |

50-60 t/m |

20-30 t/m |

20-30 t/m |

30-35 t/m |

30-65 t/m |

|

Filling Arrange |

1-300ml,2-300ml,3-20ml,5-75ml, 15-75ml, 75-250ml,5-75ml/75-150ml /150-300ml |

|||||||||

|

Power |

1.1Kw |

1.1kw |

2.2Kw |

2.2Kw |

2.2Kw |

2.2Kw |

1.1kw |

1.1Kw |

4KW |

5.5Kw |

|

Size |

1130*750*1680 mm |

1500*700*1800 mm |

1950*800*1850 mm |

1950*800*1850 mm |

1900*1400*2000 mm |

1900*1400*2000 mm |

1230*700*1400 mm

|

1230*700*1400 mm |

1450*1050*1750 mm |

1850*950*1980 mm |

|

Weight |

250Kg |

300Kg |

850Kg |

800 Kg |

850Kg |

1200 Kg |

250Kg |

250Kg |

475Kg |

850Kg |

In addition to,If you're looking for glue filling machine,adhesive filling machine,super glue filling machine,502 glue filling machine,automatic glue filling machine,AB Glue filling machine,glue tube filling machine,glue tube filling machine,Gel Glue filling machine,glue bottle filling machine,You can browse our product website more.

If you are more than interested in the machine ,you can contact us at market@micmachinery.com

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.