- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Inner wall: stainless steel 316

Jacket and outer layer: stainless steel 304

Both inner and outer are polished and handled by special light treatment.

Pot Capacity:

Primary Pot: 60L (working volume: 50L)

The core functionality of a cosmetic homogenizer mixer lies in its ability to create uniform and smooth formulations by breaking down particles and blending ingredients effectively. Equipped with high-speed rotating blades or mixing elements, these machines generate intense shear forces that disperse and homogenize the ingredients, resulting in a smooth and uniform cosmetic product. The advanced design of the homogenizer's chamber ensures efficient mixing and prevents the formation of lumps or aggregates.

Pot Lid Feeding System

This device can be connected to the tube using vacuum system, the material into the emulsifying pot, inner wall and outer are 304 high quality stainless steel, inside and outside fine casting, surface special light processing.

Oil And Water Tank

Used for pre-heating and pre-stirring materials, and then transported to the main pot for secondary stirring homogenization. The electric heating power of the sandwich layer is 2KW, and the outer layer is equipped with asbestos insulation device, which not only ensures that the heat energy is reduced and the scalding of employees is avoided. Two cases quota fixed stirring dispersions 0.55KW, so that oil and water heating more quickly and evenly.

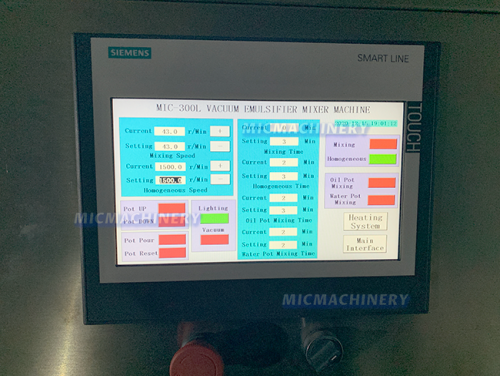

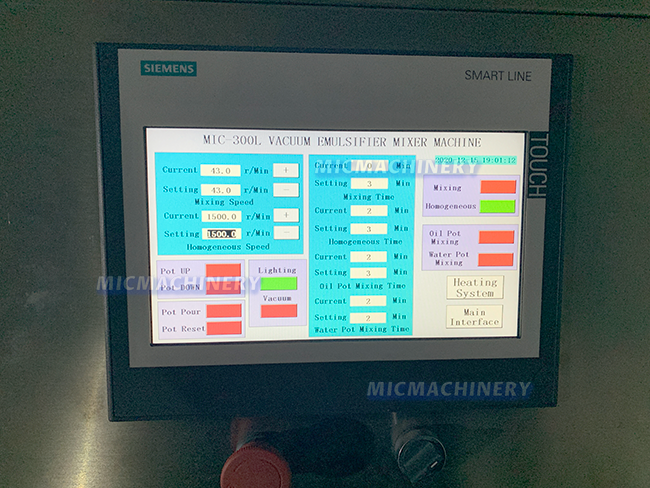

Control System

The control system is equipped with digital time relay device, so it can adjust time and speed of homogenizer based on different material. All control buttons are concentrated together,clear at a glance.

If you want to know more models of filling machine, you can refer to the table below:

|

Vacuum Homogenizer Mixer |

|||||||||||

|

Model |

10L |

30L |

50L |

100L |

150L |

200L |

300L |

500L |

600L |

1000L |

|

|

Working Capaicty |

10 |

30 |

50 |

100 |

150 |

200 |

300 |

500 |

600 |

1000 |

|

|

Emulsify |

KW |

0.75 |

1.1 |

2.2 |

3 |

4 |

4 |

4 |

7.5 |

11 |

11 |

|

Min/r |

0-2800 |

0-2900 |

0-2800 |

0-2800 |

0-2800 |

0-2800 |

0-2900 |

0-3500 |

0-3500 |

0-3500 |

|

|

Agitator |

KW |

0.55 |

1.1 |

1.1 |

1.1 |

1.5 |

1.5 |

2.2 |

2.2 |

4 |

4 |

|

Min/r |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

10-120 |

|

|

Machine Dimension |

Length |

1100 |

1650 |

1500 |

1700 |

1100 |

2600 |

1100 |

3000 |

3000 |

4800 |

|

Width |

600 |

600 |

600 |

650 |

600 |

1900 |

600 |

2500 |

1300 |

3000 |

|

|

Height |

1500 |

1700-2300 |

1900-2500 |

1700-2700 |

1700-2700 |

2500-3500 |

2500-3500 |

3200-4500 |

3200-4500 |

2500-3850 |

|

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Working ability |

Design volume: 60L |

|

Working volume:50L |

|

|

Minimum operating volume: 20L |

|

|

Material |

Contact Parts: 304 stainless steel thickness: 3mm |

|

Interlayer: 304 stainless steel thickness: 3mm |

|

|

Outer layer: 304 stainless steel thickness: 2mm |

|

|

Weight |

650kg |

|

Size |

1500mm×600mm×1900-2500 mm |

|

Service life |

10 years |

|

Stirring |

Fixed paddle stirring, PE blade Scraping |

|

Homogenizer |

Power: 2.2KW |

|

Motor speed: 2800r/min |

|

|

Particle size: 0.2-0.6um |

|

|

Uncapping |

Electric lift |

|

Heating |

Electric heating |

|

Discharge |

Tilt pot discharge and bottom valve discharge |

|

Process parameters |

Working pressure: -0.09MPa |

|

Flimsy parts |

1 year renewal except artificial |

|

Warranty period |

1 year |

|

Inverter |

Taian (Taiwan) |

|

Motor |

Huadiao (Nanjing) |

|

Reducer |

Jiahe(Zhejiang) |

|

Vacuum |

Boer Kang (Shanghai) |

|

304 stainless steel |

Taigang(Tianjin) |

|

Main electrical components |

Zhengtai(Zhejiang) |