- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Introduction:

In the realm of pharmaceutical precision, the Eye Drop Filling Machine emerges as a technological marvel, seamlessly combining innovation with the delicate requirements of ophthalmic product manufacturing. This advanced machine stands as a cornerstone in the pharmaceutical industry, providing manufacturers with a reliable solution to meet the stringent demands of eye care products. As we explore its distinctive product characteristics, diverse applications, and the intricate mechanical principles guiding its operation, we embark on a journey to unveil the essence of excellence in eye drop filling. From sterile formulations to specialized medications, this machine ensures each dropper is filled with accuracy, consistency, and the promise of promoting optimal eye health.

Product Characteristics:

The Eye Drop Filling Machine showcases an array of exceptional characteristics meticulously engineered for precision and compliance. Crafted from materials adhering to pharmaceutical standards, often stainless steel, these machines ensure longevity while upholding the highest standards of quality and hygiene. Featuring automated vial or dropper feeding, precise filling, and sealing mechanisms, they strike a delicate balance between automation and the intricacies of pharmaceutical manufacturing. Designed with user-friendly interfaces and adjustable controls, these machines accommodate various dropper sizes and formulations, ensuring each product receives a consistent and accurate fill. Equipped with anti-contamination features and sterile sealing capabilities, these machines preserve the integrity of eye drop formulations, delivering products that resonate with both quality and the promise of optimal eye care.

Product Applications:

The applications of the Eye Drop Filling Machine span the entire spectrum of ophthalmic product manufacturing, offering a comprehensive solution for efficient and precise filling and sealing of dropper bottles. Whether producing standard lubricating eye drops or specialized medications for glaucoma or infections, these machines ensure uniformity in dosage and presentation. The adaptability of the Eye Drop Filling Machine caters to the dynamic requirements of the pharmaceutical industry, where each eye care product requires a tailored approach to dispensing, capping, and preserving its unique formula.

Mechanical Principle:

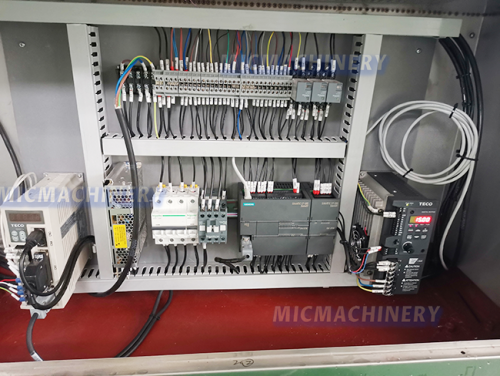

At its core, the Eye Drop Filling Machine operates on advanced mechanical principles designed for delicacy, speed, and compliance. Utilizing dropper feeding systems, dosing pumps, and filling nozzles, the machine accurately measures and dispenses the specified quantity of eye drop solution into individual dropper bottles. Sealing mechanisms, often employing high-speed technology and cleanroom conditions, secure the bottles, preserving the sterility and effectiveness of the eye drops. Integrated sensors and programmable logic controllers (PLCs) oversee the entire process, ensuring uniformity, minimizing errors, and enhancing the overall efficiency of eye drop filling operations.

In conclusion, the Eye Drop Filling Machine stands as a symbol of precision and compliance in the pharmaceutical industry. Its exceptional product characteristics, diverse applications, and advanced mechanical principles make it an indispensable asset for manufacturers globally. Embracing cutting-edge technology, this machine not only ensures the accuracy of eye drop filling but also upholds the highest standards of presentation, consistency, and quality. As a fundamental component in ophthalmic product manufacturing, it continues to shape the way eye care products are filled, ensuring each dropper embodies the essence of precision and the promise of enhanced eye health.

Filling head

When the bottle through the conveyor belt was sent to the location of the chuck, automatic identification of sensors, control by internal program to send signals for filling station, when the bottle comes under the filling head, cylinder head began to move down the drive filling, filling process without dripping, do not waste material, also can ensure the bottle clean and tidy, convenient after labeling.

Automatic sorting device for the lid

Its main role is going to filling the bottle, hand put the bottle to the machine, open the bottle on the button on the touch screen, start automatically on the bottle, the bottle to the filling machine by the conveyor belt This process greatly save labor costs, and its work efficiency is very high, save time and effort.

Screw capping head

His job is to tighten the lid on a bottle that has been filled , which is the last step on the main bench.

When the bottle reaches under the Screw capping head, the machine automatically recognizes and the Screw capping head moves downward to tighten the cap quickly.

This filling capping machine is suitable for:

E-liquid ,essential oil , VG PG seed oil into various round bottles with the filling range from 5-50 ml.

High precision cam provides a regular plate to position, cork and cap; accelerating cam makes capping heads going up and down ;constant turning arm screws caps; Peristaltic pump measures filling volume; and touch screen controls all action. No bottle no filling and no capping. The machine with advantage of high position .

1. Man-machine dialogue system setting, visual convenient operation ,accurate filling level

2. The mainframe running speed is step frequency conversion.

3. The product quantity can be controlled.

4. Multi-failure prompt function (such as depression, no filling and no inserting plug etc).

5. Automatic stop function, if there is no filling, no cap in any rail, it may stop automatically.

If you want to know more models of filling machine, you can refer to the table below:

|

Vial Filling Machine |

||||||||

|

model |

FC-30 |

FC-X40 |

FC-P35 |

FC-P40 |

FC-T30 |

FC-N25 |

FC-E35 |

FC-Z40 |

|

application |

cosmetics, daily chemical and pharmaceutical industries such as nail polish, e-liquid, eye drop,etc |

|||||||

|

Packing type |

various round and flat glass and plastic bottles,etc |

|||||||

|

speed |

23-30 pcs/min |

30-50 pcs/min |

30-40 pcs/min |

25-30 pcs/min |

20-30 pcs/min |

15-25 pcs/min |

30-40 pcs/min |

30-50 pcs/min |

|

Filling arrange |

50-250ML |

10-100 ML |

10-100 ML |

10-100 ML |

30-120 ML |

2-30 ML |

10-100 ML |

20-150 ML |

|

power |

5kw |

2KW |

2KW |

5KW |

2KW |

2KW |

2KW |

2KW |

|

size |

2000*1000*1700mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

1800*1000*1500mm |

2000*1000*1500mm |

|

weight |

650KG |

550KG |

650KG |

650KG |

650KG |

650KG |

650KG |

600KG |

in short, we will try our best to provide you with satisfactory service,the following is our customer feedback.