- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

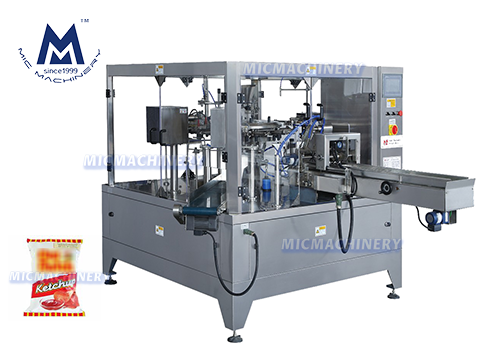

In the dynamic landscape of modern manufacturing, efficiency and precision play pivotal roles in meeting the demands of diverse industries. Automatic pouch packing machines, automatic pouch filling machines, and bag filling equipment stand at the forefront of this technological revolution, offering unparalleled advantages in terms of product characteristics, versatile applications, and advanced mechanical principles.

Product Characteristics

Automatic pouch packing machines are engineered with cutting-edge features that redefine the packaging process. These machines boast high-speed capabilities, ensuring swift and accurate filling of pouches. Precision is a hallmark, with the ability to handle various packaging materials and sizes. These machines often incorporate user-friendly interfaces, allowing operators to easily program and monitor the packaging parameters. Moreover, advancements in design prioritize durability and ease of maintenance, ensuring prolonged operational life and minimal downtime.

Product Application:

The applications of automatic pouch packing machines, automatic pouch filling machines, and bag filling equipment are vast and diverse. From the food and beverage industry to pharmaceuticals, these machines cater to the unique needs of each sector. In food packaging, these machines excel in efficiently handling a wide range of products, from powders and granules to liquids and sauces. In pharmaceuticals, they ensure the precise filling of medications for accurate dosage. Additionally, these machines find utility in industries such as cosmetics, chemicals, and agriculture, showcasing their adaptability across various sectors.

Mechanical Principle:

At the core of these machines lies a sophisticated mechanical principle designed to optimize the packing and filling processes. Automated systems control the entire workflow, from pouch feeding to filling and sealing. Auger fillers, volumetric fillers, or liquid pump systems are often integrated to ensure precise and consistent product measurements. These machines employ advanced sensors and actuators that enhance the overall accuracy of the packaging process. Furthermore, the integration of PLC (Programmable Logic Controller) technology facilitates seamless communication between different components, contributing to the efficiency and reliability of the entire system.

In conclusion, automatic pouch packing machines, automatic pouch filling machines, and bag filling equipment epitomize the fusion of innovation and functionality in the realm of industrial packaging. Their exceptional product characteristics, diverse applications, and sophisticated mechanical principles position them as indispensable assets for businesses striving for excellence in efficiency, precision, and overall product quality.

2.Automatic detection function, if the bag is not opened or opened incompletely, no feeding, no heat sealing, the bag can be reused, no waste of materials, saving production costs for users.

3.The safety device will give an alarm when the working air pressure is abnormal or the heating pipe fails.

4.Equipped with plexiglass safety door to protect operators.

5.Oil-free vacuum pump is adopted to avoid pollution of the production environment.

Suitable for milk powder,coffee,flour,spices,additive,pesticide,chemical powder weighing filling packing for premade bag,zipper bag.

Adopting PLC control,it has the advantages of stable operation and high weighing accuracy.

The width of the bag is easy to adjust and can be controlled with just one button.

Comply with GMP requirements, environmental protection and pollution-free.

All contact parts are made of 304/316 stainless steel.

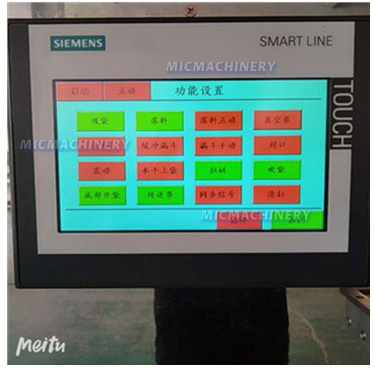

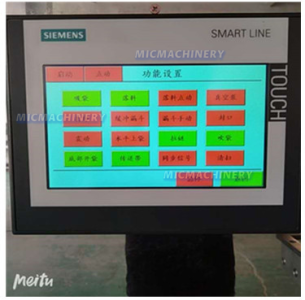

control panel

The control panel on the filling machine is the core of the machine,it consists of touch screen,power switch, emergency button You just need to press the corresponding button and the machine will follow the correct program.

An Alarm Screen will also be included on automatic filling equipment to notify packagers when there is an issue with the filling equipment or the packaging line in general. In addition to notification, the screen can assist with identifying the issue if the same is not immediately obvious.

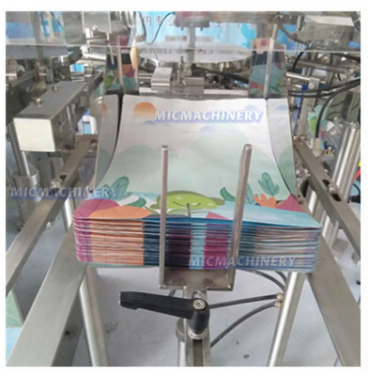

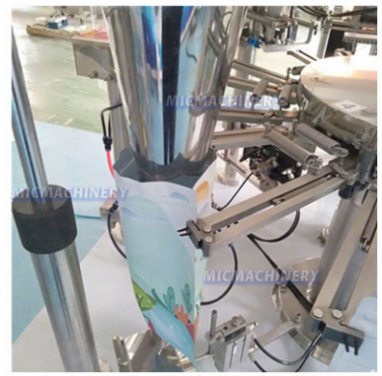

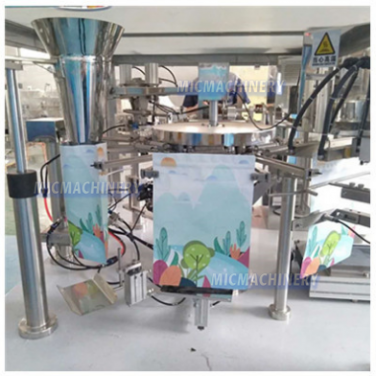

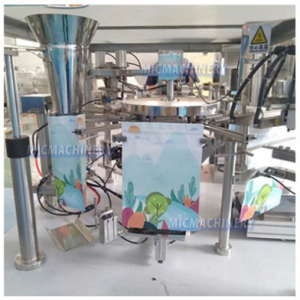

Automatic bag opening device

Its main function is to open the bag and prepare the filling materialMain work flow: suction cup will bring the bag to the main rotary plate, the main rotary plate holds the bag into the vacuum bag opening station. The bag is vacuumed by suction cups and assists in blowing air out. After the bag is opened, the filling begins, then the bag is sealed, and the final product is conveyed out of the filling machine through a conveyor belt

In addition to,we have ketchup packaging machine,tomato paste packaging machine,ketchup filling machine,tomato paste sachet packing machine,ketchup packet filling machine,ketchup sachet packing machine,ketchup pouch filling machine,ketchup packing machine,tomato sauce packing machine,sauce pouch packing machine.

If you are more than interested in the machine ,you can contact us at market@micmachinery.com

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.