- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

Description of the machine

Synchronized transmission, any change of transmission belt will be finished quickly. Compared to the type of traditional multilayer whose change and maintain need more than six hours ,it’s maintenance is easy and maintain is simple ,so it doesn’t influence production.

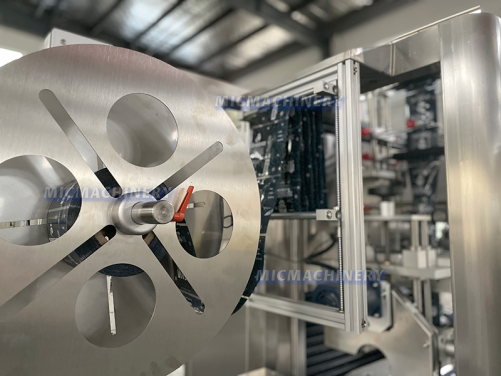

Unit cutter head plane design in China which apply to the container of ∮40mm—∮70mm.you never need to change or debug it. It also has unique light touch human-machine screen, that means, auto search original location as well as safety and convenience which is ahead of other congener products.

Single shrinking label feed plane ,reasonable height which is convenient to fix the label ;micro-computer auto figure which avoid enactment and adjustment .you only need to press it lightly ,the label will detect and locate automatically .The change of label is quick and convenient, besides ,the cut place is absolutely exact .

Label feeding equipment :driving synchronized tensility control the supply of label ,the supply ability is 90meters per minute, volume label supply plane is ∮500mm,the internal diameter of paper tube will be 4’ ,8’,10’ .the configuration of label feeding is stable tensility which enable the exact length of label and the stable ,quick supply of label .The center pillar apply step by step shoot label structure and the speed is 150B per minute for 100mm label.

The newly designed cutter head use step by servo motor driving which speed is high ,action is exact ,the cut is in order and the shrinking is beautiful .This design cooperate with the label synchronized location structure enable the precision of cut location within 1mm.

Many emergency stop buttons enable emergency stop at the proper position along the production which guarantee the safe production.

This is the description of sleeve labeling machine, bottle sleeve machine, shrink sleeve label machine.

Sleeve Labeling Machines are advanced labeling systems that are used to label products with shrink sleeves. These machines are designed to apply and shrink a heat-sensitive label onto a product, creating a tight, secure and visually appealing label. The machine operates by first feeding a roll of film with pre-printed labels through a set of rollers, which cut the labels and apply them to the product. Then, heat is applied to the sleeve, causing it to shrink tightly around the product, creating a seamless and wrinkle-free label.

These machines are commonly used in industries such as food and beverage, cosmetics, and pharmaceuticals. They are particularly popular for their ability to provide a high-quality finish and tamper-evident seal, which can help to protect the product from contamination and maintain its quality. With the ability to label a wide range of product shapes and sizes, Sleeve Labeling Machines are a versatile and reliable solution for any labeling needs.

SLM-1800 Steam Shrink Tunnel

1. In the case of different and irregular round bottles, square bottles and flat bottles etc, the new-style both steam and electricity shrinking oven is easy to adjust and maintain. It has an even shrinking .2. The distribution of low-pressure steam drum and sqouting way of steam are uniform and designed with seamless tube.

3. The nozzle is divided to be adjustable three segments and the height , position and steam output of every segment can be adjusted respectively so as to gain the perfect shrinking effect.

4 .The whole machine is made of stainless steel with heat preservation, which not only saves energy, but also comply with the international safety standard.

5 .The stainless steel defrosting tray collects condense water.

6. The whole machine adopts the water-proof design with the convenience of easy operation and low maintenance.

Stream Generator

The water is fed into the series of wholly automatic electrical heating generator by high pressure potential vortex pump made of copper with short water-supply time and durable service. A floating ball for liquid level is fixed in the water tank to automatically control the water inlet. Working system is all automatically controlled. After connecting the water supply and power supply for 5 minutes or so, it can output the steam continuously with a high level of working efficiency.

Quotation for the machine

|

Item |

Name |

Amount |

Unit |

Configuration |

Unit Price

|

Total price

|

Remark |

|

1 |

Sleeve labeling machine |

1 |

set |

4kw |

|

|

SLM-252D |

|

2 |

Shrink tunnel |

1 |

set |

0.75kw |

|

|

SLM-1800 |

|

3 |

Steam generator |

1 |

set |

24kw |

|

|

SLM-1200

|

|

4 |

mold |

2 |

pcs |

|

|

|

|

|

5 |

Conveyor |

7 |

m |

|

|

|

|

|

FOB SHANGHAI Total Price :USD25000 |

|||||||

Technical Parameters

|

Input Power Supply of Blower |

1,220VAC 0.75KW |

|

Working Pressure |

≤0.1Mpa |

|

Weight |

230kg |

|

Steam Consumption |

20-30Kg/h |

|

Size of Oven Body |

L1800mm×W600mm×H450mm |

|

Transporting Speed |

0-35m/min |

|

Input Power Supply |

220V 24kw

|

|

Steam Pressure |

0.25-0.4Mpa |

|

Vapor Generation |

24kg/h |

|

External Dimension |

L600mm x W550mm x H1200mm |

|

Weight |

96Kg |

Detail list of Selecting and Using the Accessory

|

Name |

Amount |

Unit |

Brand |

Origin |

|

PLC |

1 |

Set |

Siemens |

German |

|

Touch Screen |

1 |

Set |

Siemens |

German |

|

High-speed Optical Fiber Sensors |

2 |

Pc |

Panasonic |

Japan |

|

OPTICAL SENSORS |

4 |

Pc |

Panasonic |

Japan |

|

Label Sending Servo Motor |

2 |

Set |

Panasonic |

Japan |

|

Label Cutting Servo Motor |

2 |

Set |

Panasonic |

Japan |

|

Bottle Separate Ac Motor |

1 |

Set |

Panasonic |

Japan |

|

Bottle Separate Converter |

1 |

Set |

Panasonic |

Japan |

|

Bottle Carrying Ac Motor |

1 |

Set |

Panasonic |

Japan |

|

Bottle Carrying Converter |

1 |

Set |

Panasonic |

Japan |

|

Conveyor Converter |

1 |

Set |

Panasonic |

Japan |

|

Ac Contactor |

2 |

Pc |

Schneider |

France |

|

2P air switch |

1 |

Pc |

DELIXI |

china |

|

24V relay |

13 |

Pc |

Schneider |

France |

Toolbox detailed list

|

NO |

Name |

Specification |

Quantity |

|

1 |

Open wrench |

14、12、8、10(4 total) |

1set |

|

2 |

Movement wrench |

250*30 |

1set |

|

3 |

Inner hexagonal wrench |

7 total |

1set |

|

4 |

Clubs screwdriver |

6*100mm、3*75mm |

1set |