- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

- Customer reviews: click on

This machine is suitable for a variety of materials 50-100ML flat bottles . The high precision cam provides a regular plate positioning on the plug cover; acceleration cam provide lifting screw head, constant torque rotary cover; measuring and filling of piston pump; touch screen control. No bottle no filling and don't upload the plug and outer cap . The advantages of accurate positioning, stable transmission, protection of the bottle cap, measurement accuracy and simple operation, etc.

Filling head

When the bottle through the conveyor belt was sent to the location of the chuck, automatic identification of sensors, control by internal program to send signals for filling station, when the bottle comes under the filling head, cylinder head began to move down the drive filling, filling process without dripping, do not waste material, also can ensure the bottle clean and tidy, convenient after labeling.

Automatic sorting device for the lid

Its main role is going to filling the bottle, hand put the bottle to the machine, open the bottle on the button on the touch screen, start automatically on the bottle, the bottle to the filling machine by the conveyor belt This process greatly save labor costs, and its work efficiency is very high, save time and effort.

In short, we will try our best to provide you with satisfactory service,the following is our customer feedback.

|

Filling Volume |

10-100ml |

|

Filling nozzle |

1 head |

|

Output |

20-30 bottles each minute |

|

Filling Error |

≤±1% |

|

Power Supply |

220V/50Hz |

|

Capping Rate |

≥99% |

|

Stopping rate |

≥99% |

|

Air Supply |

1.3 m3/h 0.4-0.8Mpa |

|

Power |

2.0 kw |

|

Weight |

650 kg |

|

Dimension |

1800*1000*1500mm |

|

Name |

Brand |

|

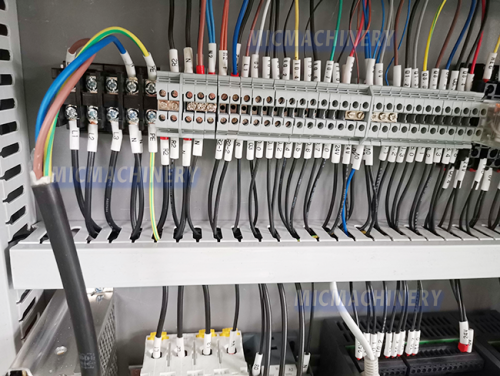

Button |

Schneider |

|

AC contactor |

Schneider |

|

Relay |

Schneider |

|

Frequency converter |

Schneider |

|

Motor |

Qi peng |

|

Air cylinder |

AIR TAC |

|

The electromagnetic valve |

AIR TAC |

|

Bearing |

NSK |

|

PLC |

Schneider |

|

Touch screen |

Schneider |

|

Photoelectric detection |

Sick |

|

If the peristaltic pump control filling will use servo motor Servo motor + drive |

Schneider |

- Penicillin bottle filling machine ( MIC-L40 Small glass Bottle Filling Corking And Seaming Machine )

- Gorilla Bottle Filling Machine(MIC-ZF4 Automatic small plastic bottle liquid filling machine)

- Oral liquid filling machine(MIC-L45 linear syrup and oral liquid filling machine)

- Syrup Filling Machine ( Speed 60-90 bottles per minute )

- Eye drops filling machine(MIC-L45 eyes drops plastic bottle with inner plug filling and capping machine)

- Gorilla Bottle Filling capping machine 2 in 1

- Eye drops high speed small volume bottle filling machine