- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

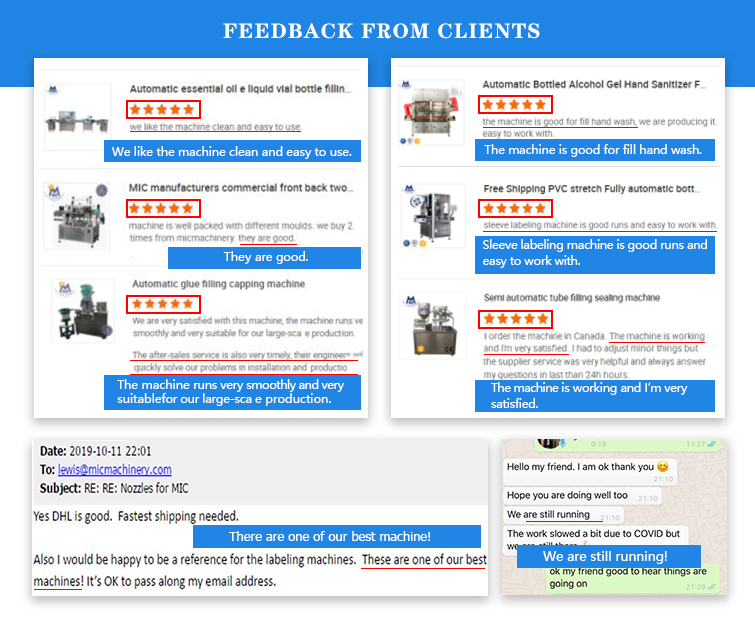

- Customer reviews: click on

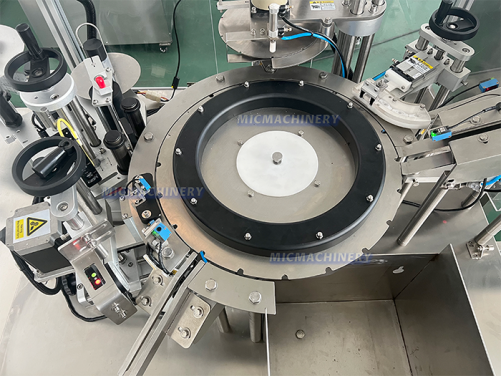

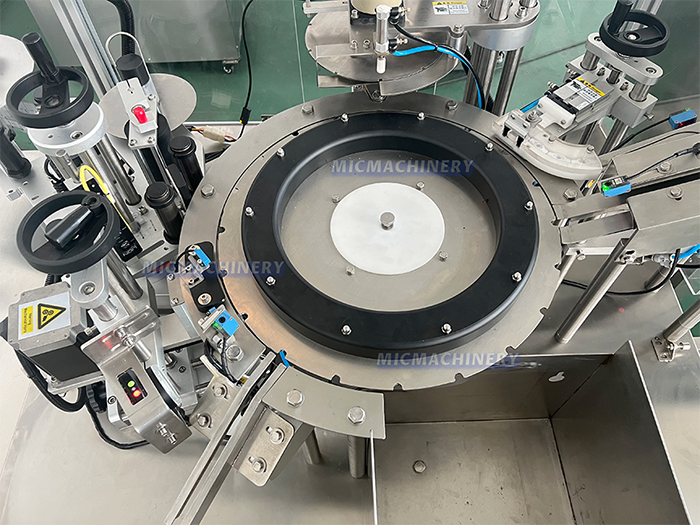

The syringe labeling machine star disk type rod printing and labeling function automatically sticks the label to the designated position of the needle tube; At the same time complete the printing batch number, production date, output count. In the case of bottle shortage, the control system guarantees not to send the label, effectively prevent the waste of label, and according to the production characteristics of each factory, the labeling speed can be stepless speed regulation, so as to ensure that the machine can be used alone or with other machines in line, pressure labeling parts can make the surface of the bottle is not very flat to get satisfactory labeling effect.

Enhance Syringe Labeling Efficiency with an Advanced Syringe Labeling Machine

Introduction:

In the pharmaceutical industry, accurate and efficient labeling of syringes is critical for product identification, patient safety, and regulatory compliance. A state-of-the-art syringe labeling machine provides a comprehensive solution to streamline the labeling process. This article delves into the technical features and benefits of a syringe labeling machine, highlighting its significance in optimizing syringe labeling operations. Discover how this advanced machine can revolutionize your labeling processes with precision and efficiency.

Automated Labeling Precision:

A syringe labeling machine automates the labeling process, eliminating the inconsistencies and errors associated with manual labeling. Equipped with advanced technology and precision controls, it ensures accurate and consistent placement of labels on syringe bodies or caps. This automated precision enhances label readability, reduces rework, and ensures compliance with regulatory guidelines.

Versatile Labeling Options:

Syringe labeling machines offer versatility in accommodating various labeling options to meet specific requirements. Whether it's wrap-around labels, front and back labels, or spot labels, these machines can handle a wide range of labeling applications. The ability to adapt to different label types and syringe sizes makes the machine highly flexible, catering to diverse production needs.

High-Speed Labeling:

Efficiency and productivity are paramount in the pharmaceutical industry. A syringe labeling machine operates at high speeds, ensuring swift label application without compromising accuracy. With adjustable labeling speeds, the machine can be tailored to match the production demands, optimizing throughput and minimizing production bottlenecks.

Advanced Control and Monitoring:

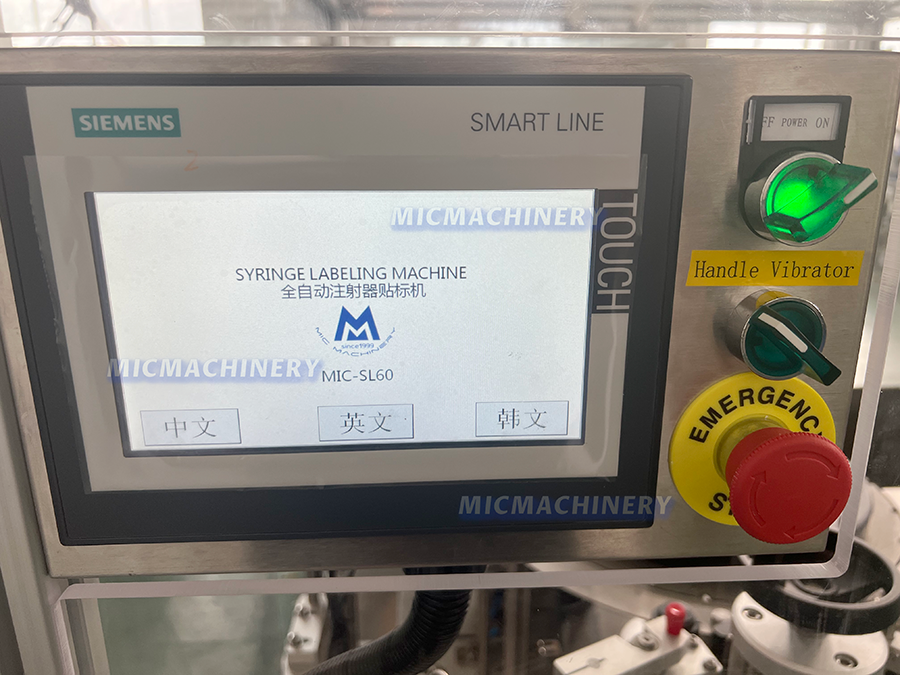

Syringe labeling machines are equipped with advanced control systems that provide real-time monitoring and precise label placement control. Operators can easily configure label parameters, adjust label positioning, and monitor the labeling process for quality assurance. This level of control enhances operational efficiency and enables quick adjustments to meet changing labeling requirements.

Seamless Integration and Compact Design:

To optimize production line efficiency, syringe labeling machines are designed for seamless integration into existing workflows. Their compact footprint allows for efficient use of limited space while maintaining high labeling capacity. The machines can be easily synchronized with other packaging equipment, ensuring a smooth and uninterrupted production flow.

Regulatory Compliance and Traceability:

Pharmaceutical manufacturers must adhere to strict regulatory guidelines and maintain traceability throughout the production process. Syringe labeling machines support compliance by accurately applying labels with essential product information, such as dosage instructions, lot numbers, and expiration dates. This promotes patient safety, enhances product integrity, and simplifies inventory management.

Conclusion:

Investing in a syringe labeling machine is a strategic choice for pharmaceutical manufacturers aiming to optimize their labeling operations. With automated precision, versatile labeling options, high-speed performance, advanced control systems, seamless integration, and regulatory compliance support, these machines revolutionize syringe labeling processes. Embrace the power of a syringe labeling machine to enhance efficiency, accuracy, and compliance in your labeling operations.

|

Item |

Data |

|

Suitable Outer diameter of syringe |

Ф 8-φ20mm |

|

Total length of syringe |

≤90mm |

|

The labeling position requires the highest distance from the syringe ear |

10mm |

|

Label length |

20-60mm |

|

Label height |

≤80mm |

|

Labeling speed |

100-150bpm |

|

Voltage |

220V/50 – 60HZ |

|

Size |

1150X1000X1400mm |