- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

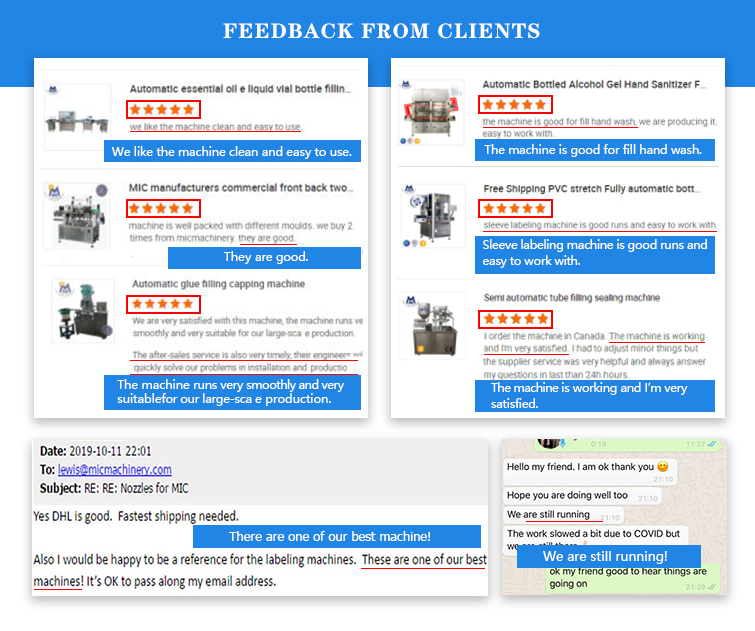

- Customer reviews: click on

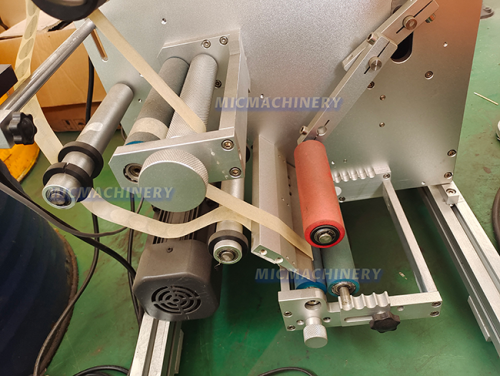

Good design and compact structure, and can be a part of small scale packaging lines.

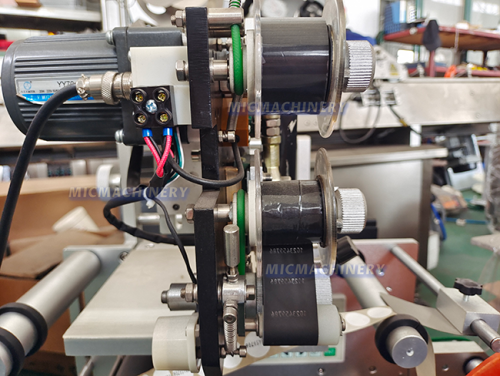

It adopts PLC control and to monitor the Electric Eye to detect the label route.

Low cost and high efficiency.

In case you need to paste transparent adhesives you must equip a special Electric Eye for it.

Boost Syringe Labeling Efficiency with a Semi-Automatic Syringe Labeling Machine

Introduction:

In the pharmaceutical industry, precise and efficient labeling of syringes is essential to meet regulatory requirements and ensure patient safety. A semi-automatic syringe labeling machine provides a cost-effective and user-friendly solution for pharmaceutical manufacturers. This article explores the technical features and benefits of a semi-automatic syringe labeling machine, shedding light on its significance in optimizing labeling processes. Discover how this versatile machine can streamline your syringe labeling operations with ease.

Semi-Automatic Efficiency:

A semi-automatic syringe labeling machine strikes a balance between manual labeling and fully automated systems. It combines the convenience of manual loading with automated label application, allowing operators to maximize efficiency while retaining control over the labeling process. This machine is ideal for small to medium-scale production environments, offering increased productivity compared to manual labeling methods.

Precise Label Placement:

Accurate label positioning is crucial to maintain compliance and readability. A semi-automatic syringe labeling machine employs advanced mechanisms and sensors to ensure precise label placement on syringe bodies or caps. Operators can adjust label position parameters and align labels with high accuracy, reducing the risk of misalignment or improper labeling.

Versatile Labeling Options:

Semi-automatic syringe labeling machines accommodate various labeling options, catering to different labeling requirements and syringe sizes. These machines can handle wrap-around labels, front and back labels, or spot labels, providing flexibility to adapt to specific product labeling needs. The versatility allows pharmaceutical manufacturers to address a wide range of labeling applications using a single machine.

User-Friendly Operation:

Designed with user convenience in mind, a semi-automatic syringe labeling machine offers a user-friendly interface and intuitive controls. Operators can easily set label parameters, adjust labeling speed, and monitor the labeling process with clarity. The machine's simplicity minimizes training requirements and ensures efficient operation, even for operators with minimal labeling experience.

Cost-Effective Solution:

For pharmaceutical manufacturers looking to enhance labeling efficiency without a significant capital investment, a semi-automatic syringe labeling machine presents a cost-effective solution. It offers improved productivity compared to manual labeling, minimizing labor costs and reducing labeling errors. This cost-effectiveness makes it an attractive option for smaller or growing pharmaceutical companies.

Conclusion:

A semi-automatic syringe labeling machine serves as a valuable asset for pharmaceutical manufacturers seeking efficient and accurate labeling solutions. With its semi-automated operation, precise label placement, versatility, user-friendly interface, and cost-effectiveness, this machine streamlines the labeling process while maintaining control and ensuring compliance. Embrace the benefits of a semi-automatic syringe labeling machine to enhance efficiency and productivity in your syringe labeling operations.

| Adopt Product Size | As Required |

| Adopt Label Size |

As Required |

| Capacity | 10-25 syringes min |

| Labeling Error | ±1mm |

| Voltage | 220V |

| Power | 100W |

| Air Pressure | 0.6-0.8Mpa |

| Controller | PLC (Germany Siemens) |

| Labeling Sensor | Sick (Germany) |

| Labeling Motor | 40W AC motor (China) |

| Bottle Sensor | LEUZE (Germany) |

| Relay | Schneider (France) |

| Air Component Airtac | Taiwan |