- Mobile: 0086-13083991987

- E-mail: market@micmachinery.com

- Shipment: exporting country

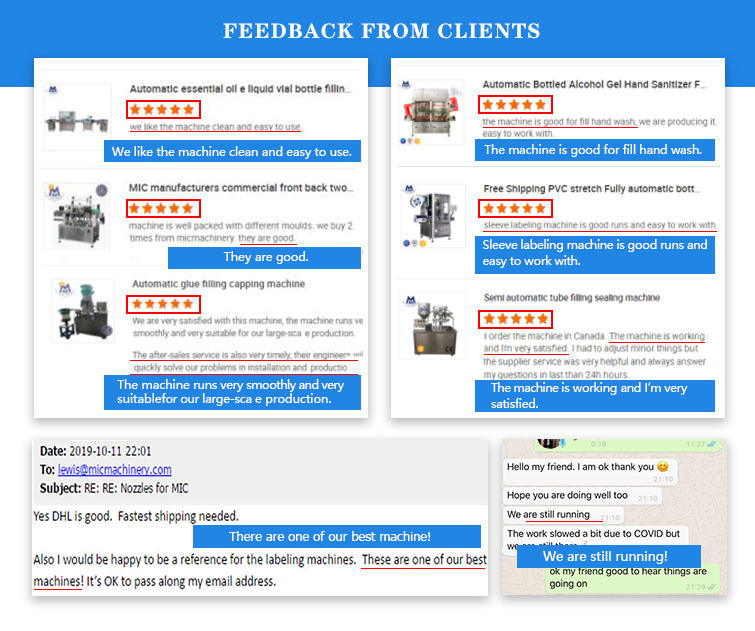

- Customer reviews: click on

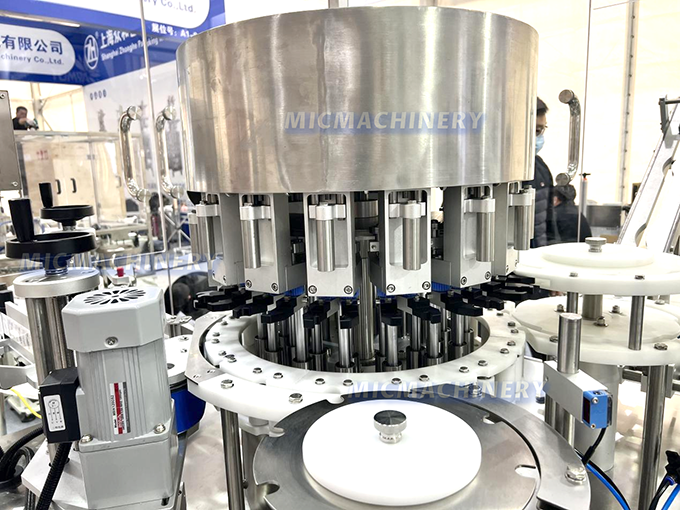

High speed syringe labeling machine continuous rod printing and labeling machine is specially designed and manufactured according to the principle of automatic labeling and technical requirements. Especially suitable for needle products; It has the advantages of compact structure, light weight, simple operation, reliable operation, convenient maintenance, fast labeling speed, smooth and beautiful labeling adaptability, etc. It is a good product in modern labeling machinery.

The continuous rod printing and labeling function automatically sticks the label to the designated position of the needle tube; At the same time complete the printing batch number, production date, output count. In the case of bottle shortage, the control system guarantees not to send the label, effectively prevent the waste of label, and according to the production characteristics of each factory, the labeling speed can be stepless speed regulation, so as to ensure that the machine can be used alone or with other machines in line, pressure labeling parts can make the surface of the bottle is not very flat to get satisfactory labeling effect.

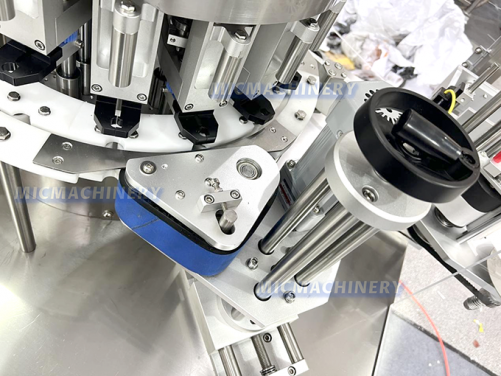

Label Engine

Roll label install on label engine , height and width can adjust according to different size label.

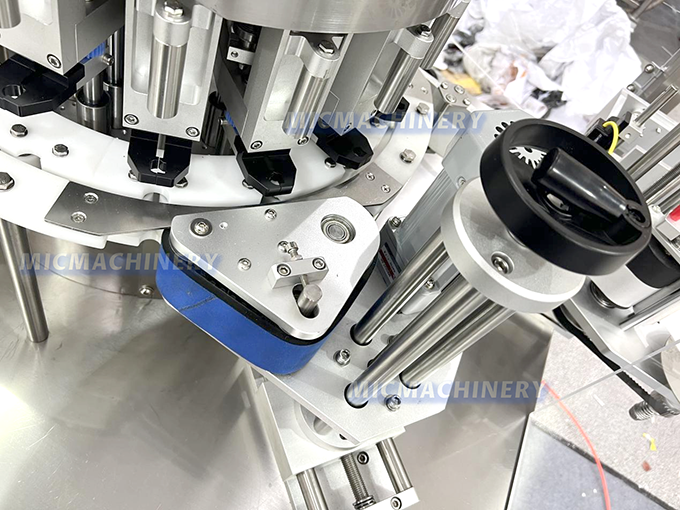

Syringe Feeding

Connect with syringe filling machine ‘s output guider , supply syringe into labeling machine dial wheels automatically

Roll Label Device

To round labeling the label when syringe on this position

Syringe Flip Holder

used to flip syringe plugging the plunger if needed.

Boost Productivity and Efficiency with a High-Speed Syringe Labeling Machine

Introduction:

In the pharmaceutical industry, accurate and efficient labeling of syringes plays a crucial role in ensuring product integrity and regulatory compliance. A high-speed syringe labeling machine offers a cutting-edge solution that enables rapid and precise label application, maximizing productivity on the production line. This article provides a technical introduction to a high-speed syringe labeling machine, highlighting its key features and benefits. Discover how this advanced machine can optimize your syringe labeling processes, saving time and enhancing overall efficiency.

Unparalleled Labeling Speed:

A high-speed syringe labeling machine is designed to handle the demands of high-volume production. It operates at exceptional speeds, allowing for rapid label application without compromising accuracy. With its high-speed capabilities, this machine significantly reduces labeling cycle times, ensuring maximum throughput and minimizing production bottlenecks.

Precision Label Placement:

Accurate label placement is vital for ensuring legibility and maintaining product aesthetics. A high-speed syringe labeling machine employs advanced precision labeling technology, which guarantees precise and consistent label placement on syringe bodies or caps. This eliminates label misalignment issues and enhances overall product quality.

Versatility and Adaptability:

To cater to diverse labeling requirements, a high-speed syringe labeling machine offers versatility and adaptability. It can accommodate various label types, including wrap-around labels, front and back labels, or spot labels. Additionally, the machine can handle different syringe sizes, allowing for seamless integration into existing production lines.

Advanced Control Systems:

High-speed syringe labeling machines are equipped with advanced control systems that provide real-time monitoring and precise label positioning control. Operators can easily adjust label parameters, such as position, orientation, and size, ensuring accurate label placement. This level of control enhances operational efficiency and minimizes label wastage.

User-Friendly Interface:

Efficient machine operation is facilitated by a user-friendly interface. High-speed syringe labeling machines feature intuitive controls and an easy-to-navigate interface, simplifying machine setup, operation, and troubleshooting. This user-centric design minimizes training requirements and maximizes productivity on the production floor.

Enhanced Productivity and Efficiency:

By automating the syringe labeling process, high-speed syringe labeling machines eliminate the need for manual labor, reducing human errors and increasing overall productivity. These machines can seamlessly integrate with other production line equipment, such as syringe filling machines or packaging systems, creating a streamlined and efficient labeling process.

Conclusion:

Investing in a high-speed syringe labeling machine is a strategic decision for pharmaceutical manufacturers aiming to optimize productivity and efficiency. With its unparalleled labeling speed, precision label placement, versatility, advanced control systems, user-friendly interface, and enhanced productivity benefits, this machine revolutionizes syringe labeling processes. Embrace the power of a high-speed syringe labeling machine to accelerate your labeling operations, meet production demands, and ensure regulatory compliance.

|

Item |

Data |

|

Suitable Outer diameter of syringe |

Ф 8-φ20mm |

|

Total length of syringe |

≤90mm |

|

The labeling position requires the highest distance from the syringe ear |

10mm |

|

Label length |

20-60mm |

|

Label height |

≤80mm |

|

Labeling speed |

0-200 bpm |

|

Voltage |

220V/50 – 60HZ |

|

Size |

1150X1000X1400mm |