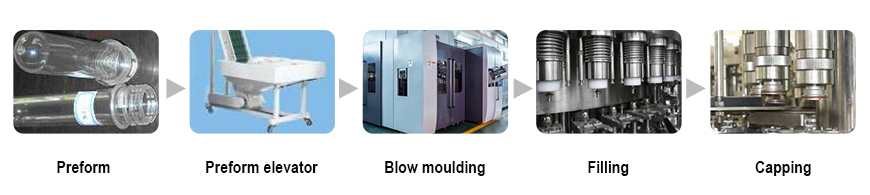

How the System Operates

These newly formed bottles are transferred directly—without external contact—into the filling module, where liquid is dispensed accurately through flow meters or gravity filling nozzles. After filling, the containers proceed seamlessly to the capping unit, where caps are sorted, placed, and tightened with precision. The entire process is completed in a sterile, enclosed environment, ensuring consistent output and excellent hygiene.

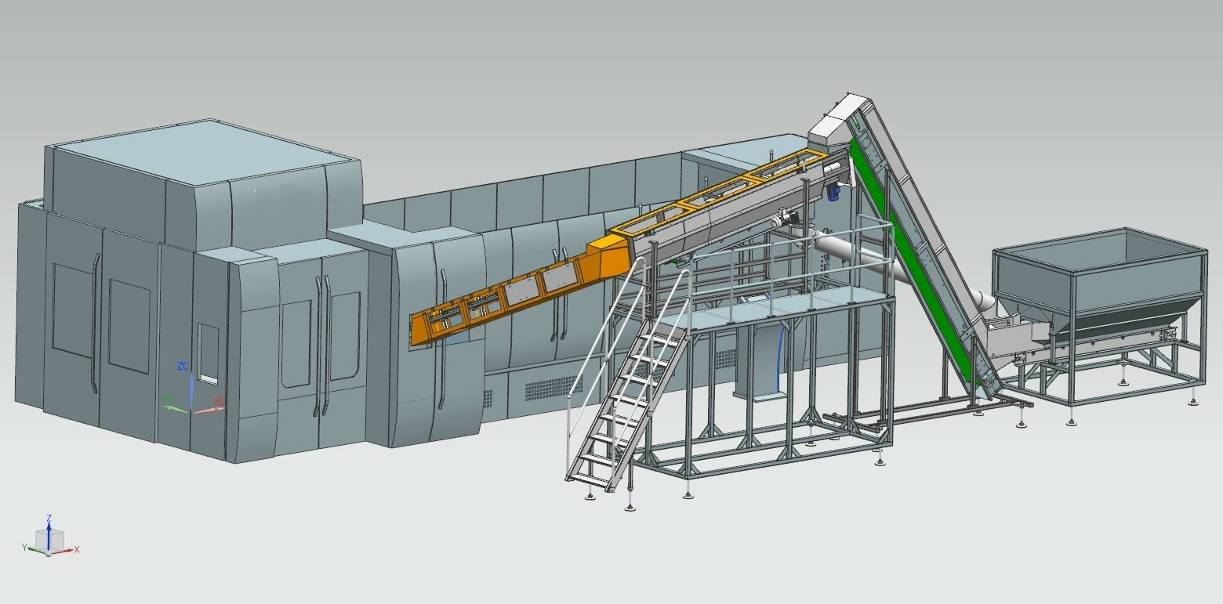

Auxiliary Equipment

To ensure smooth operation, we provide essential auxiliary devices such as preform loaders, high-pressure air compressors, chillers, cap elevators, labelers, and shrink wrapping machines. These units complement the main system by automating bottle feeding, air supply, capping, and packaging tasks—forming a complete and efficient production line. Designed to integrate seamlessly with our bottle blowing filling capping machine, these optional components enhance both speed and stability across the entire process.

Key Advantages

Our high speed blowing filling capping machine line offers major benefits:

1) PET bottle blowing rotary filling control technology integration, and synchronization

2) High-speed preform heating system design and optimization of energy-saving control technology

3) High-speed blow molding system miniaturization and optimization of mold design technology

4) Reasonable cam curve design in order to improve the quality and stability of the blowing

5) High speed and accurate filling speed control and precise level control technology

6) High-speed rotary seal synchronous control technology

7) PET bottle blowing rotary filling fast image recognition quality detection technology

8) Energy saving and noise reduction technology

Bottle Blowing Filling Capping Machine Line

☑ PLC + HMI touchscreen for intuitive operation and diagnostics

☑ Servo stretching rod ensures uniform bottle formation

☑ Precise non-contact filling valves for drip-free filling

☑ Automatic cap sorting and torque control for consistent sealing

These features make our bottle blowing filling capping machine suitable for a wide range of product types and packaging demands.

Applications

The pet bottle blowing filling capping machine is widely used in industries such as:

◆ Bottled Water: Mineral water, purified water, alkaline water

◆ Juices & Soft Drinks: Still or carbonated, including flavored water

◆ Edible Oil & Liquid Foods: Sunflower oil, olive oil, vinegar

◆ Dairy Products: Milk, yogurt drinks

◆ Non-Food Liquids: Disinfectants, liquid detergents (with customization)

This machine is suitable for various liquid viscosities and ensures a hygienic bottling process.

Technical Specifications

| Number of Working Positions | Blowing 8, Filling 32, Capping 10 |

| Rated Capacity | 18000BPH (600ml) |

| Filling Method | Gravity Filling |

| Applicable Bottle | PET bottle |

| Diameter of bottle: Φ50~Φ92mm | |

| Height of bottle: 150-320mm | |

| Applicable Cap | Normal Standard Cap |

| Installed Power | 200KW |

Why Choose Mic Machinery

By choosing Mic Machinery, you invest in durability, flexibility, and productivity. Whether you're building a new plant or upgrading an existing facility, our integrated systems ensure you stay ahead in a fast-paced, quality-driven market.

- Hot Sauce Filling Production Line

- Lube Oil Production Line

- Olive Oil Production Line

- Perfume Production Line

- Silicone Production Line

- Beer Production Line

- Tube Manufacturing Machine

- Filling Machine Manufacturer

- Visual Inspection Machine

- Bottle Blowing Machine

- Laser Coding Machine

- Aseptic Cold Filling Machine

- Fruit and Vegetable Processing Machinery Manufacturer

- Dairy Products Machinery

- Alcoholic Drink Production Equipment

- Commercial Water Treatment System

- Blowing Filling Capping Machine

- Barrel Filling Line