A Comprehensive Guide to Bottle Filling and Packing Machines

|

Model |

|||||

|

Filling Volume Range |

100-1250ML |

100-6000ML |

50-1000ML |

10-20ML/25-250ML/50-500ML/100-1000ML/250-2500ML. 1000-5000ML |

10-20ML/25-250ML/50-500ML/100-1000ML/250-2500ML/1000-5000ML |

|

Production Speed |

2000-6000Bottles/H |

1000-2500Bottles/H |

1800Bottles/H |

300-1500Bottle/H |

60-3000Bottles/H |

|

Power |

1.5kw |

1.5kw |

3kw |

0.03kw |

220kw |

|

Work Pressure |

0.7Mpa |

0.7Mpa |

0.55Mpa-0.65Mpa |

0.4-0.6MPa |

0.4-0.6MPa |

|

Weight |

3500Kg |

2500Kg |

1000Kg |

35Kg |

60Kg |

|

Dimension (L×W×H) |

2200*1800*2550mm |

2300*1400*2500mm |

2000*1400*2500mm |

1000*480*700mm |

500*580*1380mm |

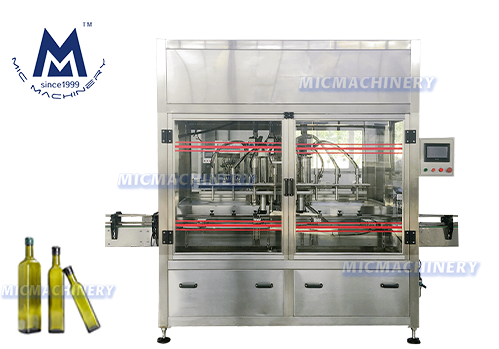

Bottle Filling and Capping Machine

A bottle filling and capping machine is a key component in any production line, designed to handle both the filling of bottles with liquid or semi-liquid products and securely capping them. This dual functionality ensures a streamlined process, reducing the need for multiple machines and increasing overall efficiency.

Automatic Bottle Filling and Capping Machine

The automatic bottle filling and capping machine is ideal for high-volume production lines. These machines are equipped with advanced automation features, allowing for precise filling and consistent capping at high speeds. They are crucial for industries where production rates and product consistency are critical.

Bottle Filling and Capping Machine Price

When considering the bottle filling and capping machine price, it’s important to balance cost with the features and capabilities that your production requires. While more advanced machines with higher speeds and greater automation will generally come at a higher price point, they offer long-term savings through improved efficiency and reduced labor costs.

Bottle Filling and Sealing Machine

A bottle filling and sealing machine goes a step further by not only filling and capping bottles but also ensuring that the seal is secure, protecting the product's integrity. This is especially important in the food and beverage industries, where maintaining product freshness is paramount.

Semi-Automatic Bottle Filling Machine

For smaller operations or those needing flexibility, a semi-automatic bottle filling machine offers a good balance between manual control and automation. These machines allow operators to control the filling process, making them ideal for small batches or products that require special handling.

Integrated Solutions: Capping, Labeling, and Packaging

Bottle Filling, Capping, and Labeling Machine

An integrated bottle filling, capping, and labeling machine combines multiple stages of the production process into a single unit. This type of machine is highly efficient, reducing the need for multiple operators and minimizing space requirements in the production area. These machines are designed to streamline operations, particularly in high-volume production environments.

Bottle Packaging Machine

A bottle packaging machine is essential for the final stage of the production line, where filled and capped bottles are packed for distribution. These machines are designed to handle various bottle sizes and types, ensuring that each bottle is securely packaged for transport.

Bottle Packing Machine Price

The bottle packing machine price varies depending on the machine’s capabilities, speed, and level of automation. Companies must evaluate their production needs and budget to select the right machine that offers the best return on investment.

Bottle Packing Machine Manual

For businesses that require a hands-on approach, a bottle packing machine manual provides detailed instructions on operating and maintaining the machine. This is particularly useful for smaller operations or those just starting, where a manual machine might be the most cost-effective option.

Manual Bottle Packing Machine

A manual bottle packing machine is operated by hand, offering flexibility and control over the packing process. This type of machine is best suited for small-scale operations or specialty products that require careful handling.

Specialized Packing Machines

Plastic Bottle Packing Machine

The plastic bottle packing machine is specifically designed to handle the challenges associated with packaging plastic bottles. These machines are optimized for speed and precision, ensuring that plastic bottles are packed efficiently without compromising their integrity.

PET Bottle Packing Machine

Similar to plastic bottles, PET (polyethylene terephthalate) bottles require specialized equipment for packaging. The PET bottle packing machine is designed to handle these lightweight, durable bottles with care, ensuring they are packed securely for transport.

Glass Bottle Packing Machine

The glass bottle packing machine is engineered to handle the fragility of glass bottles. These machines are equipped with features that gently but securely pack glass bottles, preventing breakage and ensuring that the product arrives safely at its destination.

Conclusion

Choosing the right bottle filling and capping machine, bottle packing machine, and associated equipment is essential for maintaining high production standards and ensuring product quality. Whether you need an automatic bottle filling and capping machine for large-scale production or a manual bottle packing machine for a more hands-on approach, understanding the performance characteristics of these machines will help you make informed decisions. Balancing cost with the features and capabilities that your production line requires will ensure that your investment delivers optimal returns.