Technical Introduction to Liquid Filling Equipment: Performance and Key Features

|

Model |

|||||

|

Filling Volume Range |

100-1250ML |

100-6000ML |

50-1000ML |

10-20ML/25-250ML/50-500ML/100-1000ML/250-2500ML/1000-5000ML |

10-20ML/25-250ML/50-500ML/100-1000ML/250-2500ML/1000-5000ML |

|

Production Speed |

2000-6000Bottles/H |

1000-2500Bottles/H |

1800Bottles/H |

300-1500Bottle/H |

60-3000Bottles/H |

|

Power |

1.5kw |

1.5kw |

3kw |

0.03kw |

220kw |

|

Work Pressure |

0.7Mpa |

0.7Mpa |

0.55Mpa-0.65Mpa |

0.4-0.6MPa |

0.4-0.6MPa |

|

Weight |

3500Kg |

2500Kg |

1000Kg |

35Kg |

60Kg |

|

Dimension (L×W×H) |

2200*1800*2550mm |

2300*1400*2500mm |

2000*1400*2500mm |

1000*480*700mm |

500*580*1380mm |

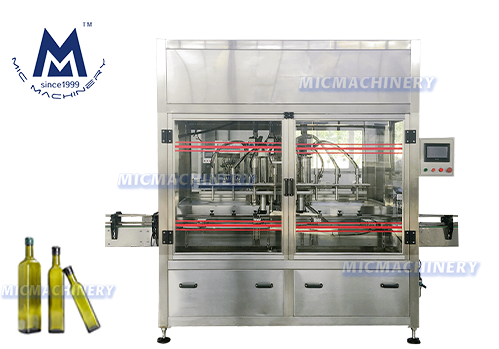

Liquid Filling Equipment

Liquid filling equipment refers to a wide range of machinery used to fill bottles, jars, and other containers with liquid products. This equipment is designed to handle various types of liquids, from thin, free-flowing liquids like water and juices to thicker, more viscous substances like syrups, gels, and creams.

Liquid Filling Equipment Suppliers

Liquid filling equipment suppliers are companies that provide these machines to industries worldwide. These suppliers offer various models, each designed to meet specific production needs. Choosing a reliable supplier is crucial for ensuring that the equipment meets the required standards and provides long-term performance.

Liquid Filling Lines and Their Components

Liquid Filling Line

A liquid filling line is a complete system that includes several machines working together to fill containers with liquid products. This line typically includes filling machines, capping machines, labeling machines, and packaging machines, all synchronized to optimize production speed and efficiency.

Liquid Filling Line Machine

The liquid filling line machine is a key component of the liquid filling line. It is responsible for accurately dispensing the liquid into containers at high speeds. These machines can be customized to handle different container sizes and liquid viscosities, ensuring flexibility in production.

Automatic Liquid Filling Line

An automatic liquid filling line offers the highest level of automation, minimizing the need for manual intervention. These lines are ideal for large-scale production, where speed, accuracy, and efficiency are critical. Automatic lines are equipped with advanced controls and sensors to ensure consistent filling and reduce waste.

Liquid Packaging Line

A liquid packaging line includes all the machinery required to fill, cap, label, and package liquid products. These lines are essential for ensuring that the products are not only filled accurately but also packaged securely for distribution. The efficiency of the packaging line directly impacts the overall productivity of the production process.

Liquid Packaging Equipment

Liquid packaging equipment encompasses all the machines used in the packaging process, from filling to sealing and labeling. High-quality packaging equipment ensures that the products are securely packaged, protecting them from contamination and damage during transportation.

Specialized Liquid Filling Equipment

Rotary Liquid Filling Equipment

Rotary liquid filling equipment is designed for high-speed production lines. It uses a rotating mechanism to fill multiple containers simultaneously, significantly increasing the production rate. This type of equipment is ideal for industries that require large volumes of liquid products to be filled quickly and efficiently.

Inline Liquid Filler and Inline Liquid Filling Equipment

An inline liquid filler and inline liquid filling equipment are designed for filling containers in a straight line. These machines are suitable for medium to high production volumes and offer flexibility in handling different container sizes and types. Inline liquid filling systems are often preferred for their simplicity, ease of operation, and cost-effectiveness.

Linear Liquid Filling Machine

A linear liquid filling machine operates by filling containers in a linear sequence. This type of machine is ideal for smaller production lines where space is limited. It offers precise control over the filling process and is suitable for various types of liquids.

Selecting the right liquid filling equipment is crucial for optimizing production processes and ensuring product quality. Whether you need a liquid filling line machine for large-scale operations or inline liquid filling equipment for more flexible production, understanding the performance and capabilities of each type of machinery is essential. By working with reputable liquid filling equipment suppliers and choosing the appropriate liquid packaging line, businesses can enhance efficiency, reduce costs, and maintain the highest standards of product quality.