Understanding Liquid Filling Machines: Performance and Applications

|

Model |

|||||

|

Filling Volume Range |

100-1250ML |

100-6000ML |

50-1000ML |

10-20ML/25-250ML/50-500ML/100-1000ML/250-2500ML/1000-5000ML |

10-20ML/25-250ML/50-500ML/100-1000ML/250-2500ML/1000-5000ML |

|

Production Speed |

2000-6000Bottles/H |

1000-2500Bottles/H |

1800Bottles/H |

300-1500Bottle/H |

60-3000Bottles/H |

|

Power |

1.5kw |

1.5kw |

3kw |

0.03kw |

220kw |

|

Work Pressure |

0.7Mpa |

0.7Mpa |

0.55Mpa-0.65Mpa |

0.4-0.6MPa |

0.4-0.6MPa |

|

Weight |

3500Kg |

2500Kg |

1000Kg |

35Kg |

60Kg |

|

Dimension (L×W×H) |

2200*1800*2550mm |

2300*1400*2500mm |

2000*1400*2500mm |

1000*480*700mm |

500*580*1380mm |

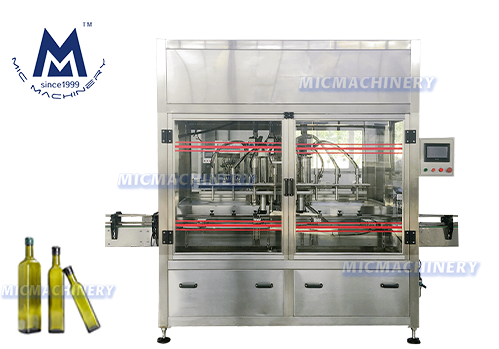

Liquid Filling Machine

A liquid filling machine is designed to fill liquids into containers, such as bottles, jars, or pouches. These machines are versatile and can handle a wide range of liquids, from water and juices to oils, creams, and gels. The primary function of a liquid filling machine is to ensure precise filling volumes, which is critical for product quality and consistency.

Automatic Liquid Filling Machine

An automatic liquid filling machine is ideal for high-volume production lines. These machines are equipped with advanced automation features, allowing for continuous operation with minimal human intervention. Automatic filling machines for liquid are particularly useful in industries where speed and efficiency are paramount, such as beverages and pharmaceuticals.

Manual Liquid Filling Machine

For smaller operations or specialty products, a manual liquid filling machine offers greater control over the filling process. These machines require manual operation, making them suitable for small batches or products that need careful handling. Manual liquid filling machines are often used in artisanal or custom production environments.

Types of Liquid Filling Machines

Semi-Automatic Liquid Filling Machine

A semi-automatic liquid filling machine strikes a balance between manual control and automation. These machines are ideal for businesses that require flexibility and precision without the need for full automation. Semi-automatic liquid filling machines are commonly used in small to medium-sized operations.

Fully Automatic Liquid Filling Machine

For large-scale production, a fully automatic liquid filling machine offers the highest level of automation and efficiency. These machines are capable of running continuously with minimal human oversight, making them ideal for high-demand industries such as food and beverage manufacturing.

Semi-Liquid Filling Machine

A semi-liquid filling machine is specifically designed to handle thicker, more viscous liquids that may not flow easily through standard liquid filling machines. These machines are commonly used for products like sauces, creams, and gels.

Liquid Filling Machine for Sale

When searching for a liquid filling machine for sale, it’s essential to consider your production needs, the types of liquids you’ll be filling, and your budget. There are various options available, from fully automated systems to manual machines, each with different capabilities and price points.

Liquid Filling Machine Price

The liquid filling machine price varies depending on the type of machine, its features, and its production capacity. Automatic machines tend to be more expensive due to their advanced technology and higher output capabilities, while manual and semi-automatic machines are more budget-friendly but require more operator involvement.

Industry Suppliers and Manufacturers

Liquid Filling Machine Manufacturer

Choosing a reputable liquid filling machine manufacturer is crucial for ensuring the quality and reliability of your equipment. Manufacturers with a proven track record offer better support, higher-quality machines, and often provide customization options to meet specific production needs.

Automatic Liquid Filling Machine Manufacturer

An automatic liquid filling machine manufacturer specializes in producing machines that offer high-speed, automated filling solutions. These manufacturers are often at the forefront of technology, offering the latest innovations in liquid filling automation.

Liquid Filling Machine Supplier

A liquid filling machine supplier plays a key role in providing access to a range of machines and ensuring they meet industry standards. Suppliers often work with multiple manufacturers, offering a variety of options to match different production requirements.

Semi Automatic Liquid Filling Machine Price

The semi automatic liquid filling machine price can vary based on the machine’s features, such as the type of liquid it can handle, its production speed, and the level of automation. These machines offer a cost-effective solution for businesses looking to increase efficiency without investing in fully automated systems.

Manual Liquid Filling Machine Price

The manual liquid filling machine price is typically lower than that of automated machines, making it an attractive option for small businesses or startups. Despite the lower cost, these machines still offer reliable performance for low to medium-volume production.

Industry Applications and Performance

Liquid Filling Companies

Liquid filling companies utilize a range of filling machines to package products for various industries. These companies often require machines that can handle different types of liquids, from water-thin substances to thick creams, ensuring versatility and efficiency in their production lines.

Conclusion

Whether you need a liquid filling machine for a small artisanal operation or a fully automatic liquid filling machine for large-scale production, understanding the different types and their performance is essential for making the right choice. By considering factors such as production volume, liquid type, and budget, you can select a machine that meets your specific needs, ensuring efficiency, consistency, and product quality.

Liquid filling machines are essential tools across various industries, ensuring accurate and efficient filling of liquids into containers. This article provides a comprehensive overview of different types of liquid filling machines, emphasizing their performance, applications, and key considerations for selection. The focus will be on specific keywords, including chemical liquid filling machine, rotary liquid filling machines, best liquid filling machine, small liquid filling machine, piston liquid filling machine, and vial liquid filling machine.

Understanding Liquid Filling Machines

Chemical Liquid Filling Machine

A chemical liquid filling machine is designed specifically for handling hazardous or reactive liquids, often found in the chemical industry. These machines are built with materials that resist corrosion and contamination, ensuring the safe and precise filling of chemicals such as acids, solvents, and other aggressive liquids. The performance of a chemical liquid filling machine is critical in maintaining safety standards and product integrity.

Rotary Liquid Filling Machines

Rotary liquid filling machines are high-speed filling solutions that use a rotating mechanism to move containers through the filling process. These machines are ideal for large-scale production, offering efficiency and speed. The rotary liquid filling machine is commonly used in the beverage, pharmaceutical, and cosmetics industries where high output and consistency are required.

Specialized Liquid Filling Machines

Best Liquid Filling Machine

When searching for the best liquid filling machine, it's essential to consider factors such as accuracy, speed, ease of use, and compatibility with different types of liquids. The best machines offer a balance of performance and reliability, ensuring consistent results across various production runs.

Small Liquid Filling Machine

For businesses with limited space or small-batch production needs, a small liquid filling machine is the perfect solution. These machines are compact yet efficient, designed to handle lower volumes without compromising accuracy. The small liquid filling machine price is generally lower than that of larger models, making it an economical choice for startups or specialty product lines.

Key Features of Liquid Filling Machines

Piston Liquid Filling Machine

A piston liquid filling machine is ideal for handling viscous liquids like gels, creams, or thick sauces. This type of machine uses a piston to draw liquid into a cylinder and then pushes it out into the container, ensuring precise filling volumes. The performance of a piston liquid filling machine is particularly valued in industries where product consistency and quality are paramount.

Liquid Filling Machine Small

A liquid filling machine small is tailored for operations where space is limited, and the production scale is modest. Despite its size, this machine offers robust performance, making it suitable for a wide range of applications, from cosmetics to pharmaceuticals.

Vial Liquid Filling Solutions

Vial Liquid Filling Machine

A vial liquid filling machine is specialized for filling small containers, such as vials, which are commonly used in the pharmaceutical industry. These machines ensure that each vial is filled accurately, maintaining the sterility and integrity of the product. The precision and performance of a vial liquid filling machine are crucial in applications where dosage accuracy is critical.

Performance Considerations and Pricing

Small Liquid Filling Machine Price

The small liquid filling machine price is typically more affordable than larger machines, making it an attractive option for small to medium-sized enterprises. However, despite the lower cost, these machines do not compromise on performance, offering precise and efficient filling for a variety of liquids.

Conclusion

Whether you're in need of a chemical liquid filling machine for hazardous materials, a rotary liquid filling machine for high-speed production, or a vial liquid filling machine for pharmaceutical applications, selecting the right equipment is crucial. The performance of these machines directly impacts product quality, operational efficiency, and overall production costs. By understanding the features and capabilities of each type, you can choose the best liquid filling machine that meets your specific needs, ensuring consistent and reliable results in your manufacturing process.