|

Model |

||||||||

|

Speed |

60 pcs/min |

60 pcs/min |

60 pcs/min |

60 pcs/min |

60 pcs/min |

60 pcs/min |

60 pcs/min |

80-120 pcs/min |

|

Diameter |

φ11-22, φ25-38 |

φ11-35 |

φ11-22, φ25-38 |

φ11-22, φ25-38 |

φ11-22, φ25-38 |

φ11-22, φ25-38 |

φ11-22, φ25-38 |

80-120 pcs/min |

|

Length |

≤150mm |

180mm |

≤185mm |

≤150mm |

≤185mm |

≤150mm |

≤150mm |

80-120 pcs/min |

|

Power |

5.5Kw |

2.2Kw |

0.75Kw |

2.2 Kw |

0.75Kw |

4 Kw |

3.5Kw |

41Kw |

|

Size |

2980*2020*1420mm |

2100*1750*1100mm |

5132*1300*3040mm |

3000*1600*2150mm |

5132*1300*3040mm |

2300*1800*1100mm |

2230*1600*1800mm |

5620*2400*2950mm |

|

Weight |

3.6 ton |

1.3 ton |

1.95 ton |

2.2 ton |

1.95 ton |

4.2 ton |

4.2 ton |

5 ton |

● 60T Extrusion Press Machine: Shapes aluminum into precise tube blanks.

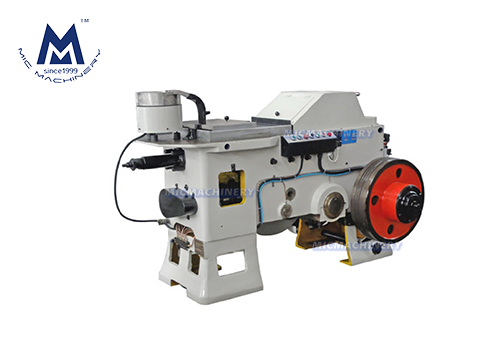

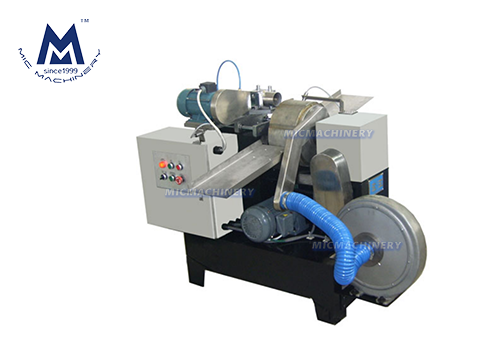

● Trimming Machine: Cuts the tubes to exact lengths.

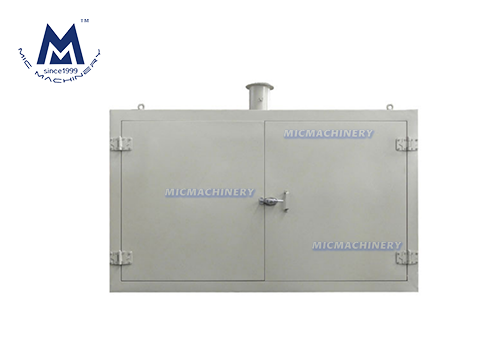

● Annealing Oven: Softens aluminum for better flexibility.

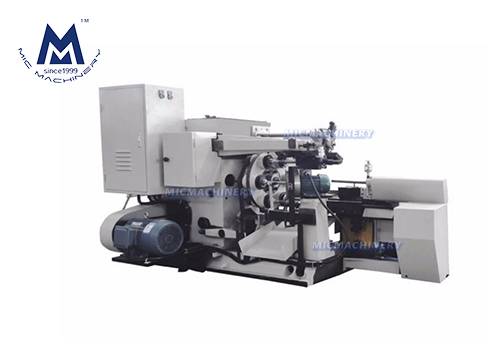

● Internal Coating Machine: Applies protective coatings to the inside of the tube.

● Lacquering Oven & Base Coating Machine: Apply smooth external finishes and coatings.

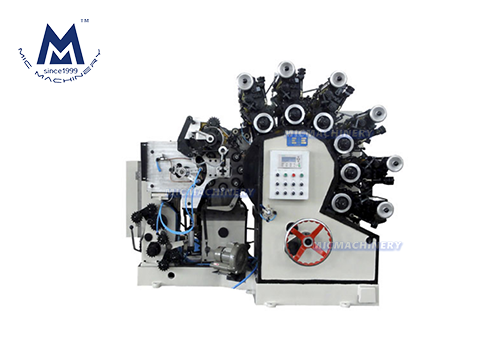

● 6 Color Tube Body Printing Machine: Prints high-quality designs on the tube surface.

● Drying Oven: Ensures quick and efficient drying of coatings.

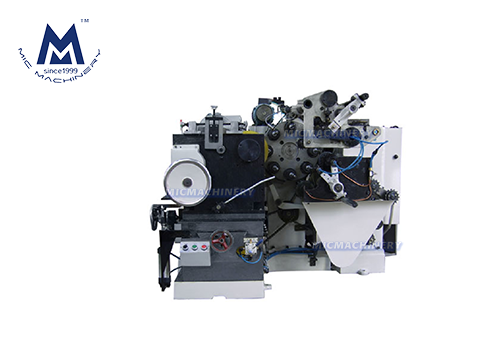

● Capping & Latexing Machines: Securely seals the tubes and adds extra protection.

2)Premium Build Quality – Constructed from high-grade aluminum profiles with SUS 304 stainless steel panels for a durable, hygienic, and aesthetically pleasing design.

3)User-Friendly & Eco-Efficient – Upgraded system for easier operation, reduced labor costs, lower failure rates, simple maintenance, and energy-efficient performance that supports environmental sustainability.

Quality is paramount in the Tube Manufacturing Machine Line. The Internal Coating Machine ensures that each tube is safely coated to prevent contamination, while the Lacquering Oven and Base Coating Machine guarantee a flawless exterior finish. The Drying Oven effectively speeds up the curing process, improving productivity. In addition, the line is flexible enough to handle various tube sizes and coating requirements, offering manufacturers the versatility to meet diverse customer needs, from cosmetics to pharmaceuticals.

Why Choose MIC Machinery?

MIC offers high-quality, automated solutions that reduce manual intervention and operational costs. Our machines are built for long-term use, with advanced features that enhance production efficiency. With strong after-sales support and tailored solutions, we ensure our customers’ needs are always met. Our systems help businesses reduce waste while maintaining top-notch product quality.

Conclusion

The MIC Automatic Aluminum Collapsible Tube Manufacturing Machine Line is a comprehensive and efficient solution for producing aluminum tubes. From extrusion to sealing, each step is designed for precision and reliability. With MIC, you get a high-performance production system backed by expert support to keep your business ahead of the competition.