Technical Introduction to Skincare Filling Machines

A skincare filling machine is designed to automate and optimize the filling process for various skincare products. From serums and lotions to creams and gels, these machines provide precise and efficient filling solutions tailored to the unique requirements of skincare formulations.

|

Model |

|||||

|

Filling Heads/Nozzles |

8 heads |

1 head |

1 head |

1 head |

1 head |

|

Filling Volume Range |

50-1000ml |

20-100ml |

2-300ml |

1-100 grams |

10ml-5000ml |

|

Production Speed |

≤1800 Bph (1000ml bottle) |

30-40 Bottles/min |

20-30 tubes/min |

20-40 bags/min |

1-50 bottles/min |

|

Power |

3Kw |

2Kw |

1.1Kw |

1180W |

220W |

|

Air Pressure |

0.55Mpa-0.65Mpa |

0.4-0.8Mpa |

0.6-0.8Mpa |

- |

0.4-0.6MPa |

|

Weight |

1000kg |

500kg |

250kg |

260kg |

60 kg |

|

Dimension (L×W×H) |

2000×1400×2500mm |

1530×2990×1500mm |

1230×700×1400mm |

800×800×1800mm |

500×580×1380mm |

|

Suitable Container |

Ф40mm-Ф100mm |

- |

- |

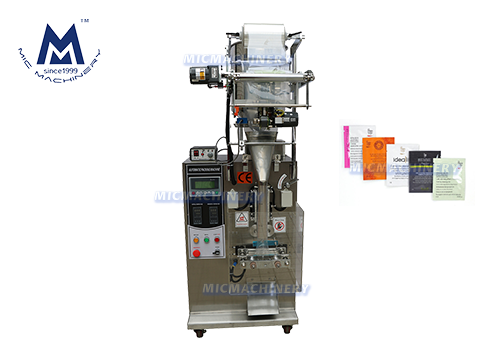

Sachets (L: 20-160mm, W: 20-100mm) |

Bottles |

|

Applications |

Oil, Sauce, Skincare |

Skincare, Gel, Cream |

Cosmetic, Cream, Lotion |

Honey, Ketchup, Oil |

Sauce, Oil, Cream |

1.Precision and Accuracy

Importance: The accuracy of a skincare filling machine is crucial for maintaining product consistency and avoiding overfilling or underfilling.

Performance: Advanced machines feature automated sensors and controls to ensure each product is filled to the exact volume, enhancing overall quality and reducing waste.

2.Versatility

Importance: Skincare products vary widely in viscosity and packaging types. A versatile skincare filling machine can handle different formulations and packaging formats, from bottles and jars to tubes and sachets.Performance: Machines equipped with adjustable nozzles and settings offer flexibility to accommodate various product types, ensuring smooth operation across different formulations.

Importance: Efficiency in filling operations impacts production speed and cost-effectiveness.

Performance: High-speed skincare filling machines streamline the filling process, allowing for increased production capacity and reduced labor costs. Automated features such as filling, capping, and labeling further enhance overall efficiency.

4.Sanitation and Hygiene

Importance: Maintaining high standards of cleanliness is essential in skincare manufacturing to prevent contamination.Performance: Modern skincare filling machines are designed with easy-to-clean components and materials that comply with hygiene regulations, ensuring a safe and sanitary production environment.

Importance: The ease of use affects the efficiency of the production process and operator satisfaction.

Performance: User-friendly interfaces and intuitive controls make it simpler to set up and operate the machine, reducing training time and operational errors.

Choosing the Right Skincare Filling Machine

● Product Compatibility: Select a skincare filling machine that is compatible with the specific types of skincare products you manufacture, considering factors like viscosity and packaging requirements.

● Production Volume: Match the machine’s capacity with your production needs, whether for small batches or large-scale operations.

Conclusion

Investing in a high-quality skincare filling machine is essential for achieving precise, efficient, and hygienic filling operations in the skincare industry. By focusing on performance aspects such as accuracy, versatility, efficiency, and sanitation, businesses can ensure the reliable production of high-quality skincare products that meet consumer expectations and industry standards.

Welcome to the forefront of skincare packaging innovation with Micmachinery. As leaders in the industry, we specialize in providing state-of-the-art skincare filling machines designed to meet the unique demands of the skincare and cosmetics sector. Explore our cutting-edge equipment, meticulously engineered for precision, versatility, and efficiency in skincare product filling.

Our Advanced Skincare Filling Solutions

Precision in Every Drop: Our skincare filling machines are crafted with precision at the forefront. Whether you're filling delicate serums, creams, or lotions, our technology ensures a consistent fill level, preserving the integrity of your skincare formulations.

● Versatility for Various Products: Our machines cater to a diverse range of skincare products, from liquid serums to thicker creams. Adaptability is key, and our skincare filling solutions seamlessly handle different viscosities and textures, providing versatility in your product lineup.

● Efficiency Redefined: Experience streamlined operations with our skincare filling machines. Engineered for high-speed production, our equipment optimizes your skincare packaging line, reducing downtime and enhancing overall efficiency.

● User-Friendly Interface: Our machines feature intuitive interfaces, making them easy to operate and adjust. Minimize training time and empower your production team with equipment designed for user convenience and quick changeovers.

Why Choose Micmachinery?

At Micmachinery, we go beyond providing machines; we offer comprehensive solutions for your skincare packaging needs. Our team of experts combines technical expertise with a deep understanding of the skincare industry to deliver tailored solutions for your filling requirements. We prioritize quality, precision, and customer satisfaction.

Elevate Your Skincare Filling Experience Today

Ready to enhance your skincare production capabilities? Explore our range of skincare filling machines and discover how Micmachinery can be your trusted partner in precision skincare filling technology. Contact us today to discuss your unique requirements and experience the difference in skincare packaging innovation.